Solid separating device

A solid separation and support frame technology, which is applied in the direction of solid separation, classification, chemical instruments and methods, etc., can solve the problems of difficult cleaning, high maintenance cost, screen blockage, etc., and achieve the effect of uniform feeding and high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

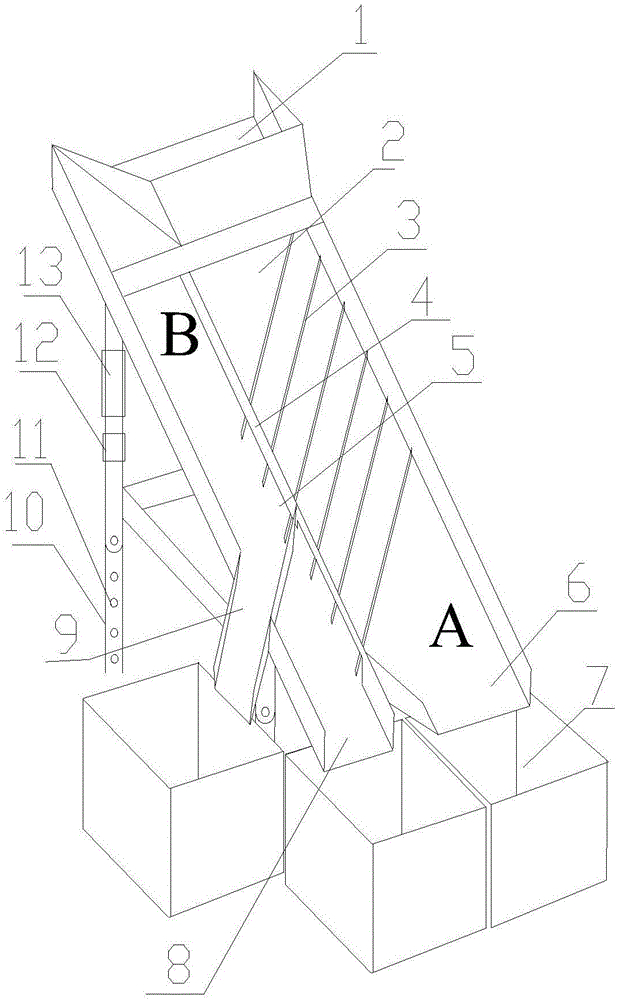

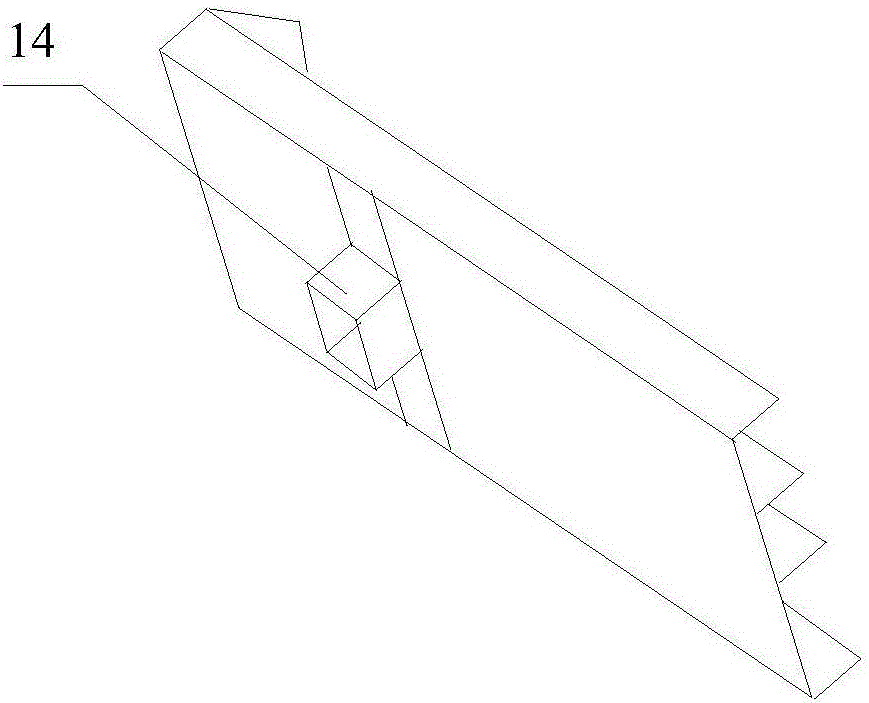

[0020] Such as figure 1 , figure 2 Shown, a kind of solid sorting device is characterized in that: comprise support frame (10), support frame (10) is obliquely fixed by vibrator (14) and separation liner (2); inclination angle can be adjusted by support rod ( 11) Adjustment, the separation liner (2) is two parallel grooves, the top of the groove A is provided with a feed port (1), the bottom of the groove A is provided with a first discharge port (6), and the groove A is provided with a first discharge port (6). There are several separating ribs (3) arranged obliquely downward in groove A; the bottom end of groove B is provided with a second outlet (8), and groove A and groove B are separated by a separation baffle (4). The middle part of B is also provided with a third discharge port (9), the separation baffle (4) is trapezoidal, and the separation baffle (4), separation edge (3) and separation liner (2) form the separation hole (5), The aperture of the separation hole lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com