Stamping forming method of big-flange high-turnup pipe orifice reinforcing piece

A technology of stamping forming and reinforcing parts, which is applied in the field of forming sheet metal parts and stamping forming parts made of high-temperature alloy materials, which can solve the problem of thinning of flanging thickness, large amount of thinning of flanging holes, and failure to meet the high strength of aircraft structure and other issues to achieve the effect of strong persuasiveness, stable product quality, and easy promotion and realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

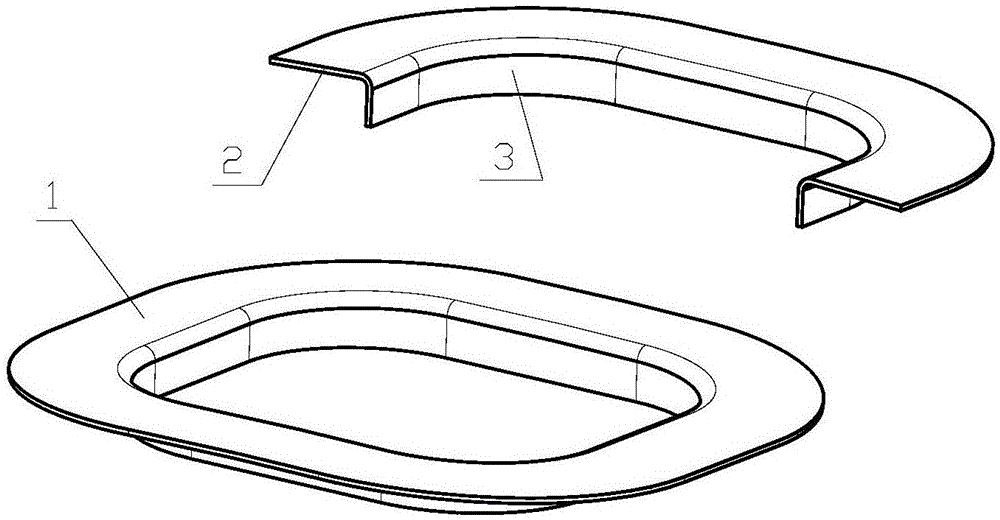

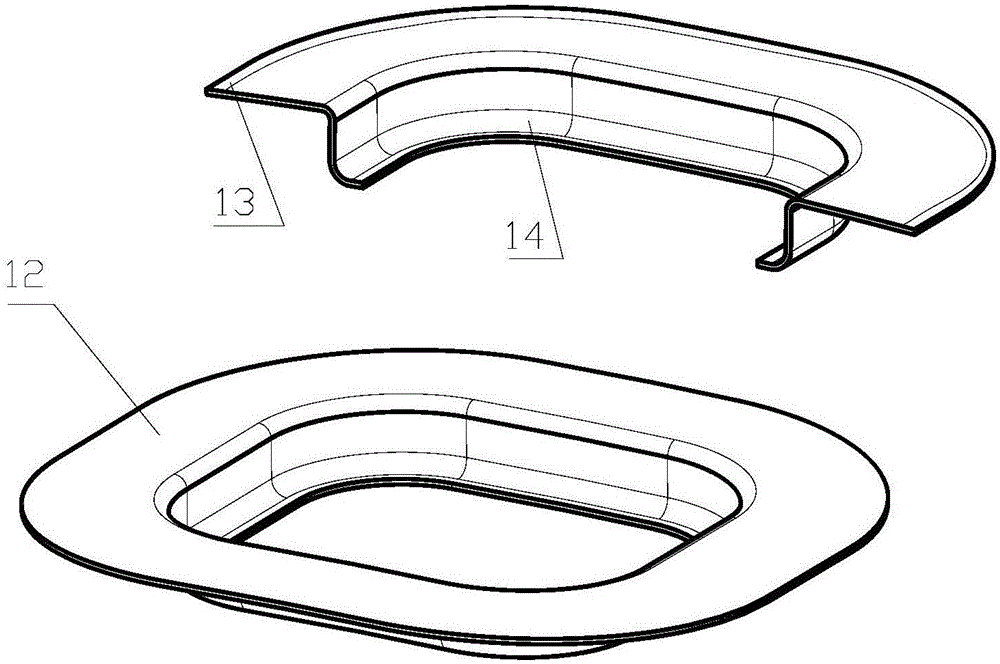

[0032] Referring to the accompanying drawings, the aircraft parts provided by the embodiment are as figure 1 As shown, the part is a large flange, high flange nozzle reinforcement 1, and the main body includes two major parts of the outer edge flange 2 and the side wall flange 3. The cross-section of the stiffener is simply Type, the biggest problem in forming by using the prior art is that the flange 2 is seriously wrinkled or the side wall flanging 3 is thinned out of tolerance.

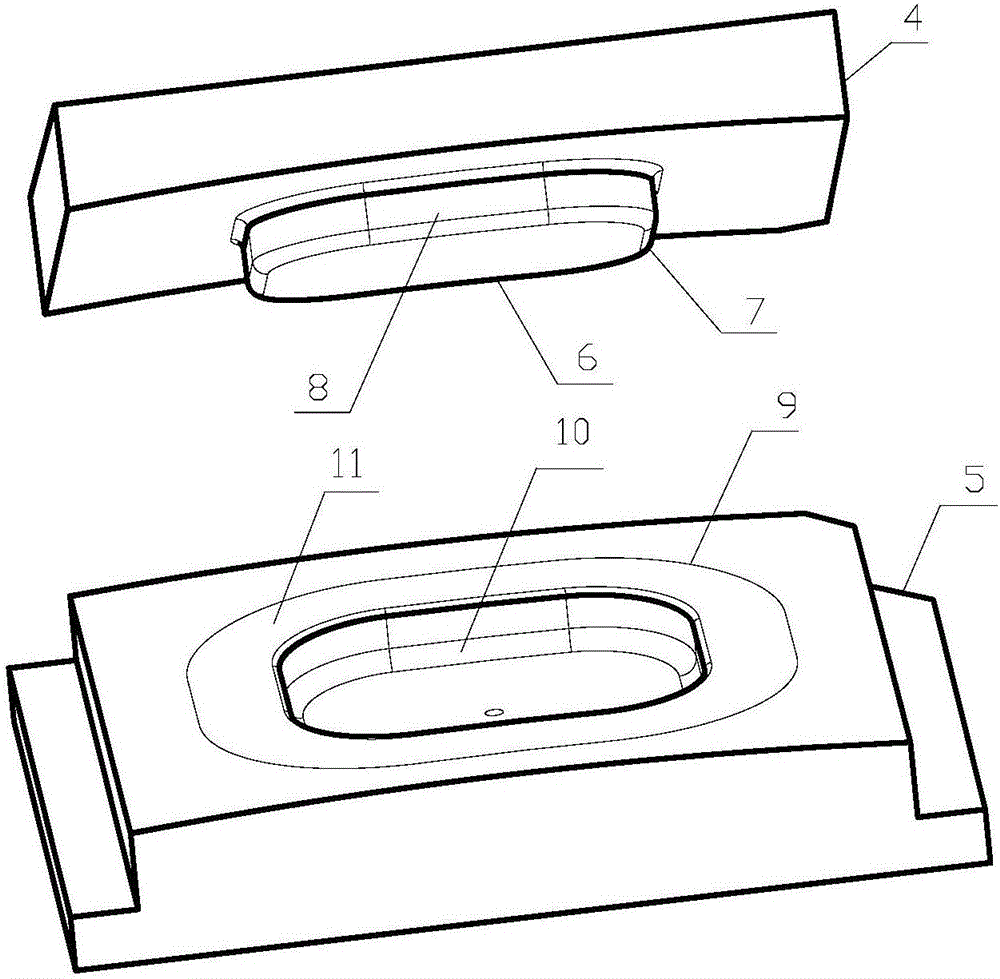

[0033] Such as Figure 2-6 As shown, a new type of large flange, high flanging nozzle reinforcement stamping forming method, including the following steps:

[0034] Step 1: Determine the stamping die structure

[0035] The forming die that this application proposes is as figure 2 As shown, the mold includes a male mold 4 and a concave mold 5, a vent hole is provided in the center of the bottom of the concave mold cavity 11, and the concave mold 5 is provided with an outer edge line 9 of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com