Position-based steel rail length measurement system and measurement method

A technology for length measurement and rail, which is applied to measurement devices, mechanical measurement devices, sawing machines, etc., can solve the problems of rail length measurement deviation, unqualified rails, and difficult to find, and achieve the effects of easy implementation, easy calibration, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

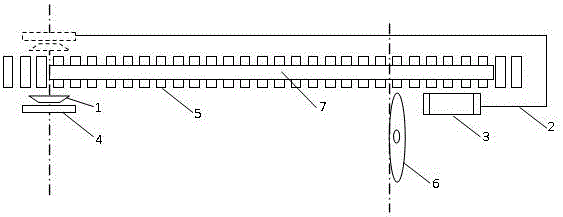

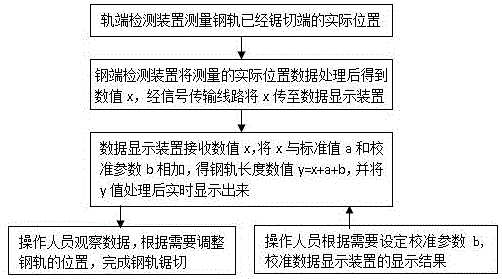

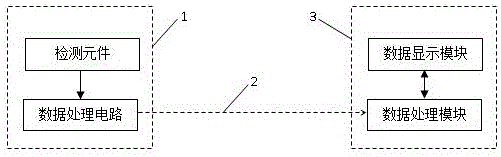

[0026] figure 1 and image 3 It shows that a position-based rail length measurement system of the present invention includes sawing equipment 6, rail end detection device 1, signal transmission line 2 and data display device 3; Disc saw blade; rail end detection device 1 is installed on the fixed brackets 4 on both sides of the rail conveying roller table 5, including a data processing circuit and a detection element, and the detection element is a group of infrared emitters symmetrically arranged on both sides of the rail conveying roller table 5 Diodes and a group of infrared receiving diodes; the infrared rays formed by the infrared emitting diodes and the infrared receiving diodes form a detection area on a horizontal plane, the center line of the detection area is perpendicular to the center line of the length direction of the rail, and it is close to the rail with the sawing equipment to prepare for sawing The vertical distance between the saw surfaces of the circular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com