Transferring type automatic ink supply system based on flexibly-packaged ink

A flexible packaging and ink technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of not adding on demand, drying and can no longer be used, and no environmentally friendly treatment methods for ink storage tanks, so as to reduce the occurrence of failures High efficiency, conducive to environmental protection and recycling, and reduce the effect of manual maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0047] The embodiment of the present invention relates to the provided automatic ink supply system based on flexible packaging ink, which can realize the fully automatic filling process of ink from the ink packaging container to the ink pool, and can effectively prevent the waste of ink caused by low temperature and oxidative drying.

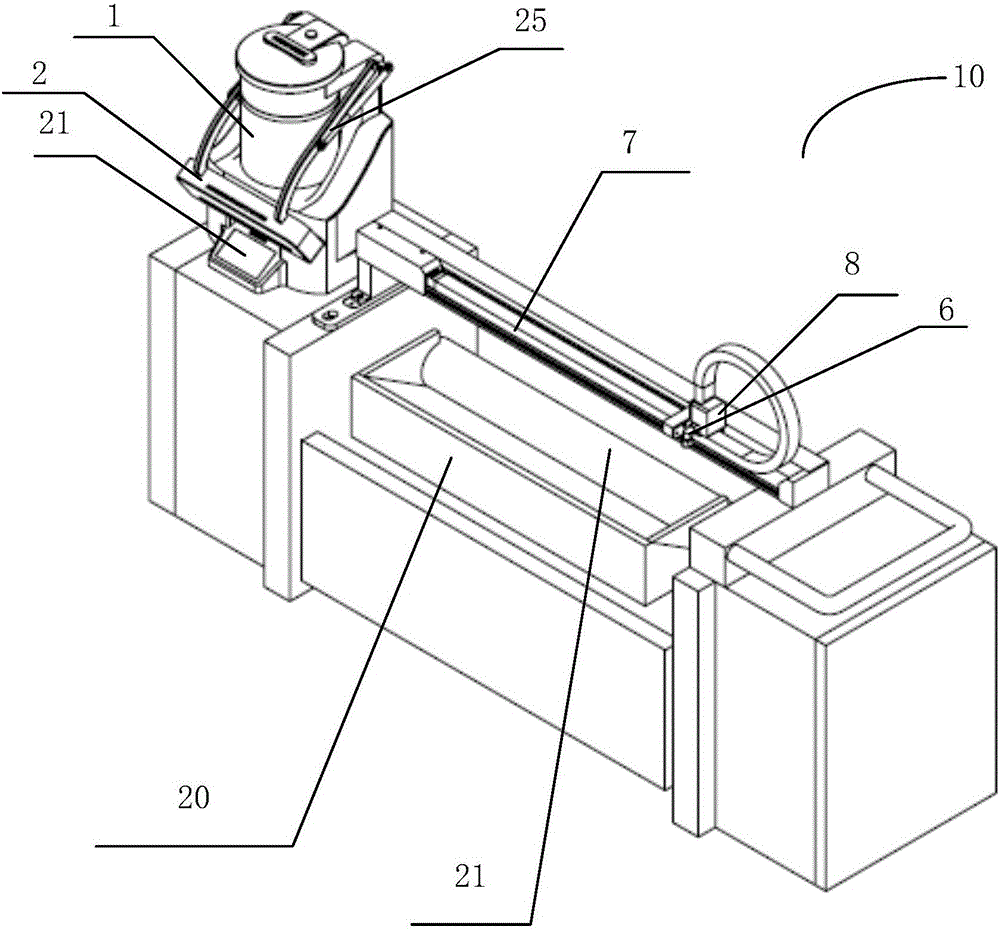

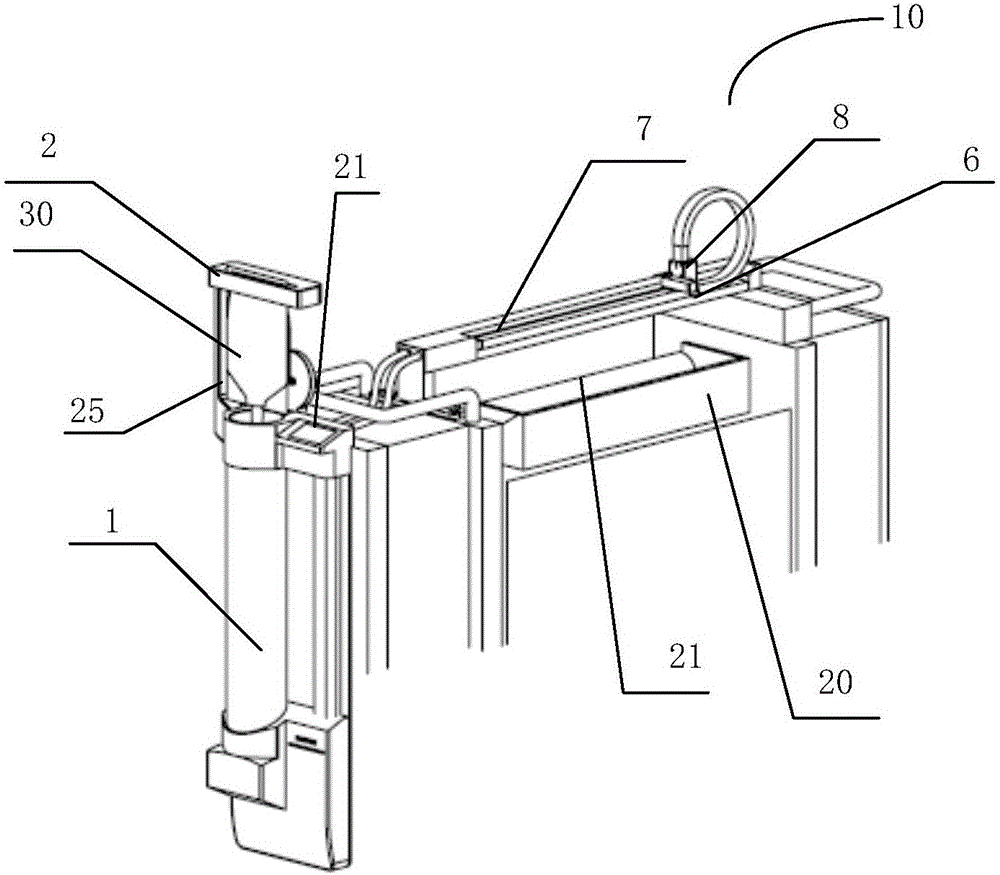

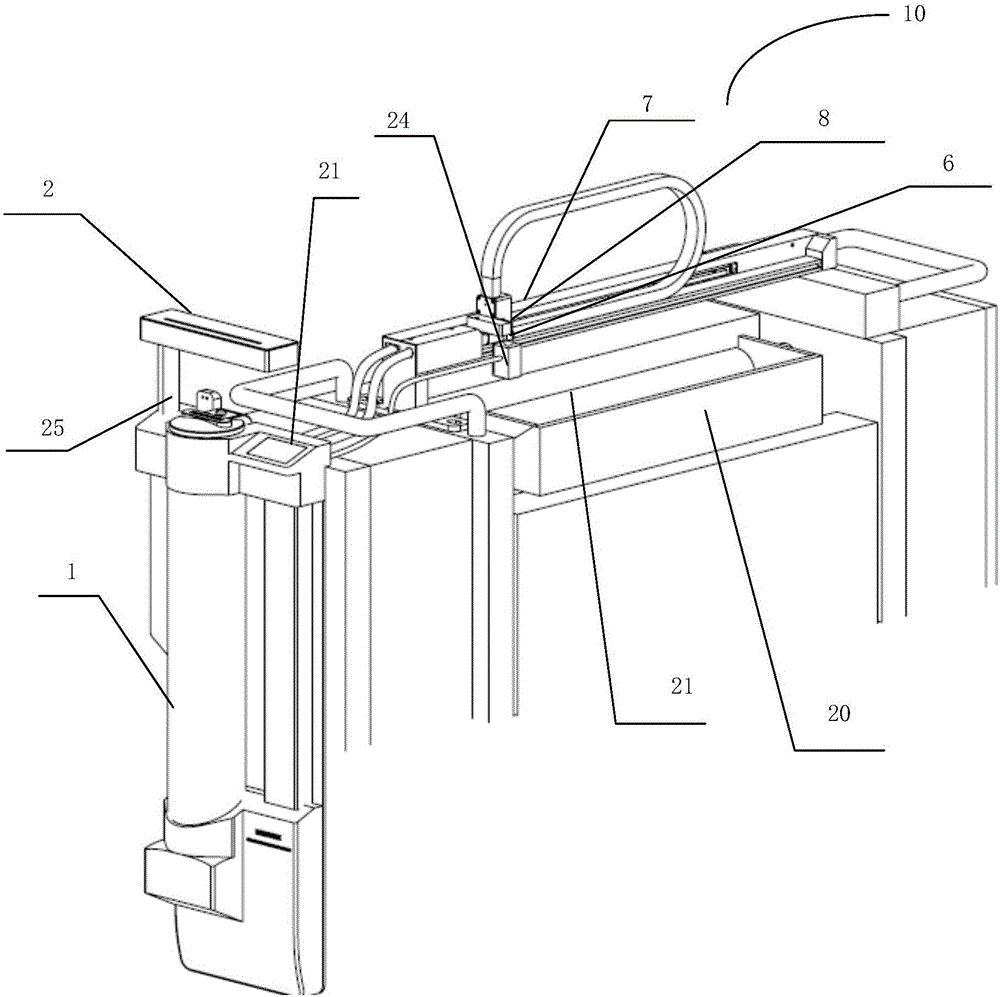

[0048] figure 1 , figure 2 Shown is the transfer type automatic ink supply system based on flexible packaging ink provided in this embodiment, wherein, figure 1 Automatic ink supply system for wall-mounted ink tanks, figure 2 An automatic ink supply system for desktop ink storage barrels; image 3 It is a better way to realize the automatic ink supply system of the desktop ink storage tank; Figure 4 Schematic diagram of the specific structure of the ink storage tank; Figure 5 A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com