Metal tray and processing method thereof

A technology of metal pallets and processing methods, which is applied in the field of freight facilities, can solve the problems of pallet deformation and bending, limit the support strength and load capacity of metal pallets, and achieve the effects of improving firmness, rigidity and load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

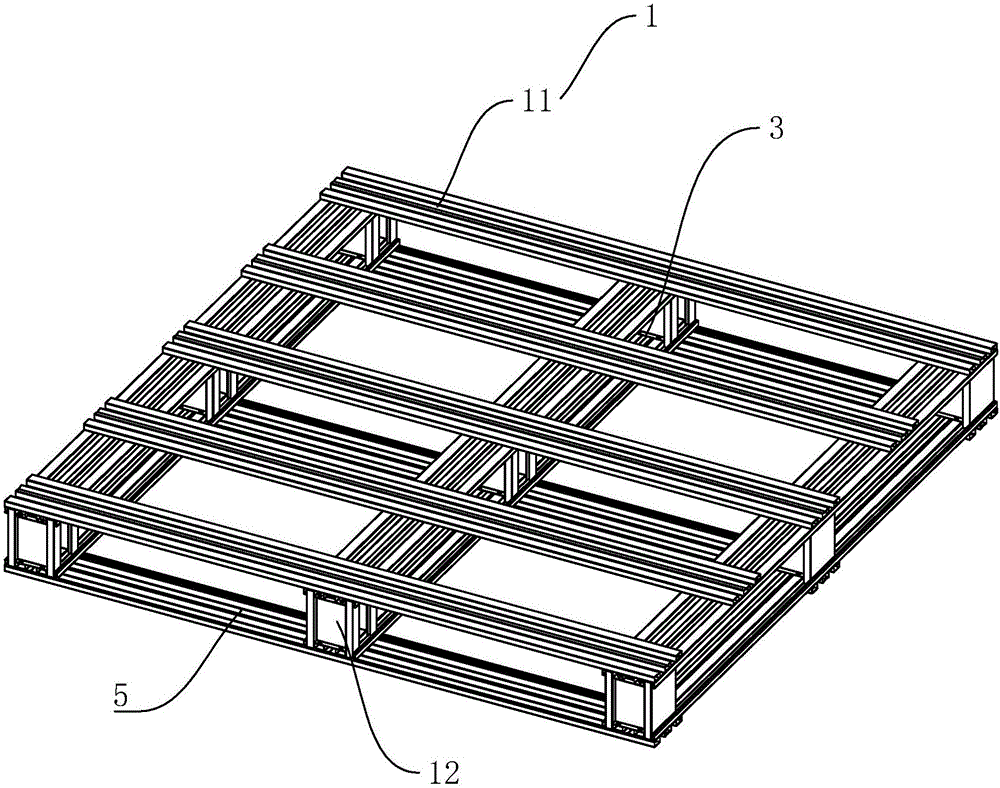

[0047] Embodiment 1: a kind of metal tray, such as figure 1 As shown, the metal tray is set as a cuboid as a whole, its upper and lower surfaces are square, and its height is smaller than the side length, so that the gravity of the heavy objects placed on the surface of the metal tray can be dispersed, and the smaller the height, the better its pressure resistance and bearing capacity. The stronger the capacity, this setting can greatly enhance the load-bearing capacity of the metal pallet.

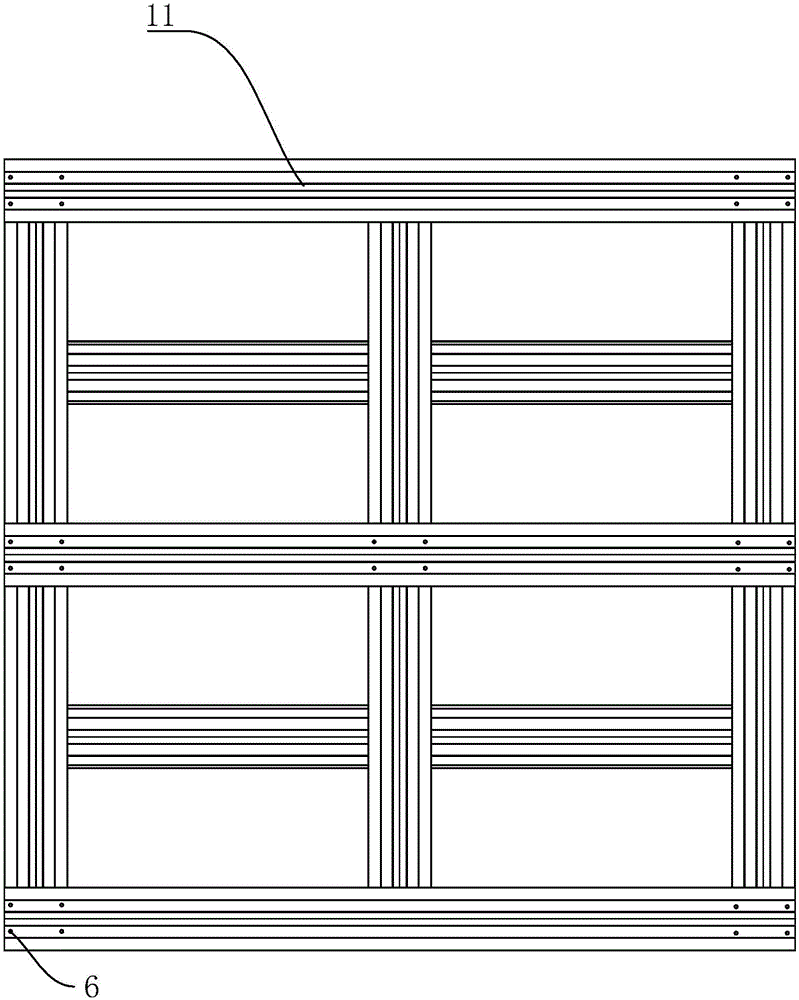

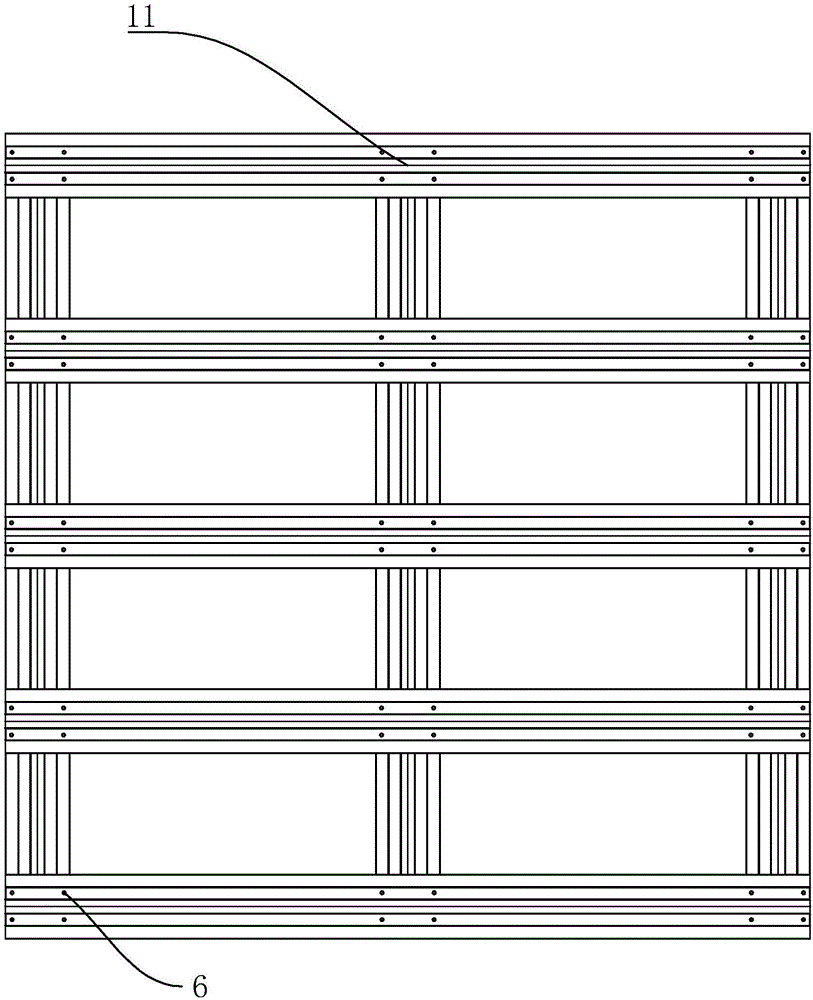

[0048] Such as figure 1 with figure 2 As shown, the metal tray is divided into three parts, the top is the upper load-bearing plate 1, the bottom is the lower load-bearing plate 5, and the middle is fixed by the support beam 3. The upper load-bearing plate 1 is composed of five parallel and equidistant load-bearing bars 11. The load-bearing plate 5 is composed of three identical load-bearing bars 11. The upper and lower load-bearing plates 5 are arranged in parallel, and the middle sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com