Ferromagnetic nano alpha-Fe2O3 with iron defects, and preparation method thereof

A ferromagnetic, -fe2o3 technology, applied in the field of ferromagnetic nano-α-Fe2O3 and its preparation, can solve the problems of metal defects and other problems, and achieve the effect of low synthesis cost and strong magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

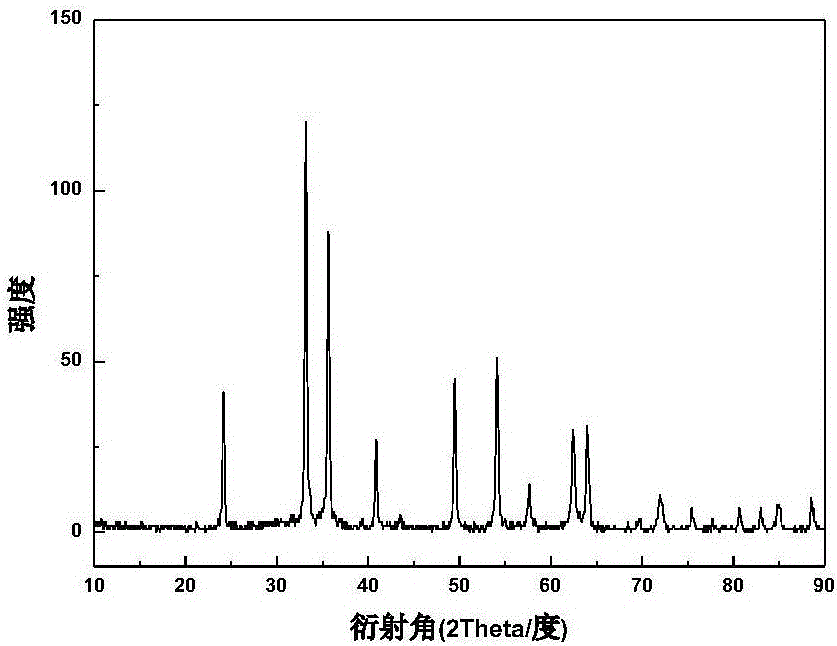

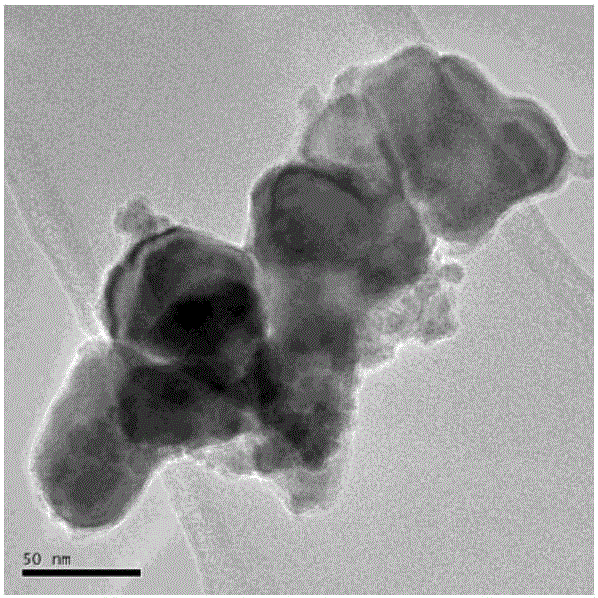

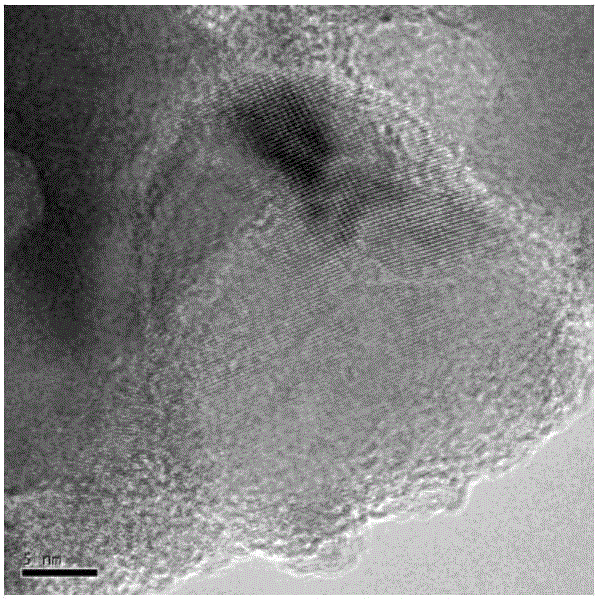

[0033] Example 1: Mix 1 g of iron acetate, 20.0 g of glycerin and 100 mL of ethanol, and stir to obtain a homogeneous solution that is transferred to an autoclave polytetrafluoro liner. Put the polytetrafluoroethylene liner into the autoclave, seal it, place it in a constant temperature oven, and react in the oven at 120°C for 6.0h. After the reaction is over, the autoclave is quenched. After the autoclave was cooled to room temperature, the hydrothermal precipitate was taken out, and after being centrifuged and washed with ethanol, it was dried. The dried powder was calcined at 700 °C for 2 h in a muffle furnace, and then cooled naturally. The prepared samples showed strong ferromagnetism, the saturation magnetization was 13emu / g, and the coercive force was 1200Oe.

example 2

[0034] Example 2: 3g ferric oxalate, 24.0g glycerin and 200mL ethanol were mixed, and the homogeneous solution obtained by stirring was transferred to an autoclave polytetrafluoro liner. Put the polytetrafluoroethylene liner into the autoclave, seal it and place it in a constant temperature oven, and react in the oven at 100°C for 15.0h. After the reaction is over, the autoclave is quenched. After the autoclave was cooled to room temperature, the hydrothermal precipitate was taken out, and after being centrifuged and washed with ethanol, it was dried. The dried powder was calcined at 600 °C for 4 h in a muffle furnace, and then cooled naturally. The prepared samples showed strong ferromagnetism, the saturation magnetization was 20emu / g, and the coercive force was 1600Oe.

example 3

[0035]Example 3: Mix 0.5 g of ferric citrate, 10.0 g of glycerin and 50 mL of ethanol, and stir to obtain a homogeneous solution that is transferred to an autoclave polytetrafluoro liner. Put the polytetrafluoroethylene liner into the autoclave, seal it and place it in a constant temperature oven, and react in the oven at 180°C for 2.0h. After the reaction is over, the autoclave is quenched. After the autoclave was cooled to room temperature, the hydrothermal precipitate was taken out, and after being centrifuged and washed with ethanol, it was dried. The dried powder was calcined at 400 °C for 8 h in a muffle furnace, and then cooled naturally. The prepared samples showed strong ferromagnetism, the saturation magnetization was 15emu / g, and the coercive force was 1300Oe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com