Pre-coating film with anti-counterfeiting key and anti-counterfeiting lock function

A pre-coating film and functional technology, applied in the direction of film/sheet release coating, film/sheet adhesive, transportation and packaging, etc., can solve the functional limitations of anti-counterfeiting, and is not very suitable for low-end packaging Market, high prices and other issues, to achieve a good anti-counterfeiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The steps to make an unlocking tablet are as follows:

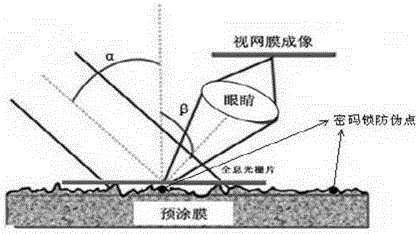

[0045] 1) Design the interference shading pattern through the computer pattern software, and realize the optical interference (at the same frequency) through the shading printed by the ink of the gravure printing machine. The composition method of unlocking anti-counterfeiting is composed of lines, and it is also designed with interference stripes to prevent scanning, so that it cannot be copied.

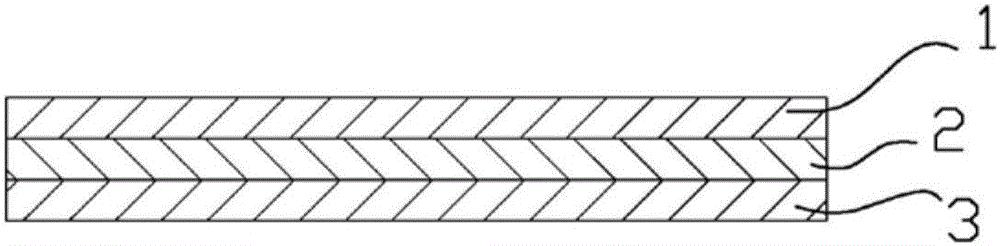

[0046] 2) Coating the molded resin layer 2 on the polyester film layer 1 .

[0047] 3) Using a thermal molding process at 90-160° C. to mold grating indentations on the thermoplastic molded resin layer 2 to form a molded grating stripe layer 3 , with a grating indentation depth of 1 μm.

Embodiment 2

[0049] The steps to make an unlocking tablet are as follows:

[0050] 4) Design the interference shading pattern through the computer pattern software, and realize the optical interference (at the same frequency) through the shading printed by the ink of the gravure printing machine. The composition method of unlocking anti-counterfeiting is composed of lines, and it is also designed with interference stripes to prevent scanning, so that it cannot be copied.

[0051] 5) Coating the molded resin layer 2 on the polyester film layer 1 .

[0052] 6) Using a thermal molding process at 90-160° C. to mold grating indentations on the thermoplastic molded resin layer 2 to form a molded grating stripe layer 3 , the depth of the grating indentations is 10 μm.

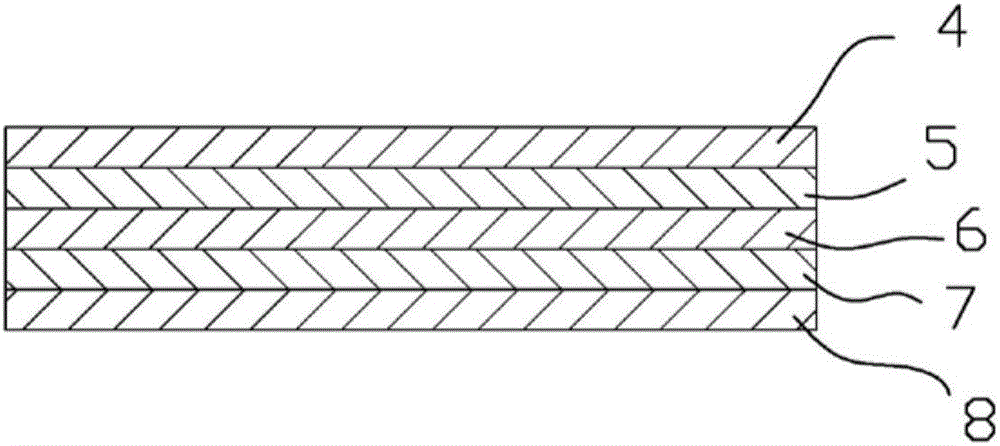

[0053] The steps to make a seal lock are as follows:

[0054] 1) Use a gravure printing machine to print transparent and colored inks on the gravure printable film layer 5 to form an anti-counterfeit pattern and form a gravure p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com