A lint collecting device

A collection device and lint technology, which is applied in the field of lint treatment devices for dryers, can solve the problems of lint falling, pipe blockage, and difficulty in cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

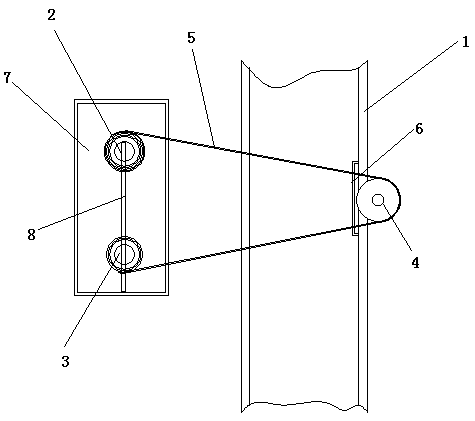

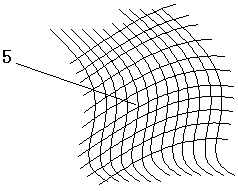

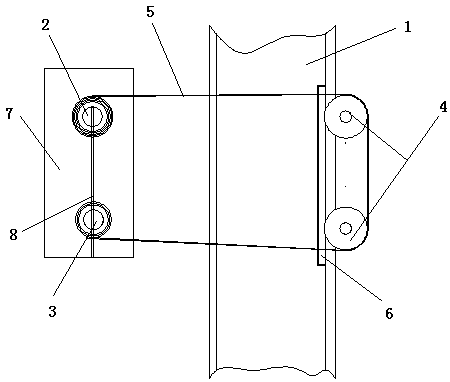

[0020] The first embodiment: as Figure 1-2 As shown, a wire waste collection device includes a first roller 2 and a second roller 3 located on one side outside the pipeline 1, and the other side of the pipeline 1 is opposite to the first roller 2 or / and the second roller. A third roller 4 is arranged at the roller shaft 3, and a wire dust adsorption belt 5 is wound on the first roller shaft 2, and the wire dust adsorption belt 5 passes through the pipeline 1 from the first roller shaft 2, and passes through the second roller shaft 2. The three rollers 4 are recovered by the second roller 3 afterward, and the lint adsorption belt 5 is a mesh adsorption belt with viscose on the surface.

[0021] The second roller shaft 3 is connected with a power device, the pipeline 1 has a pressure sensor 6, and the pressure sensor 6 is electrically connected with the power device.

[0022] The first roller shaft 2 and the second roller shaft 3 are housed in a box body 7 , and the box body 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com