Steam mop

A technology of mop and steam, which is applied in the field of steam mop, can solve the problems that the water tank and the water tank mounting seat cannot be disassembled, the operation is inconvenient, and labor-intensive, etc., and achieve the effect of thorough cleaning, easy taking out and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

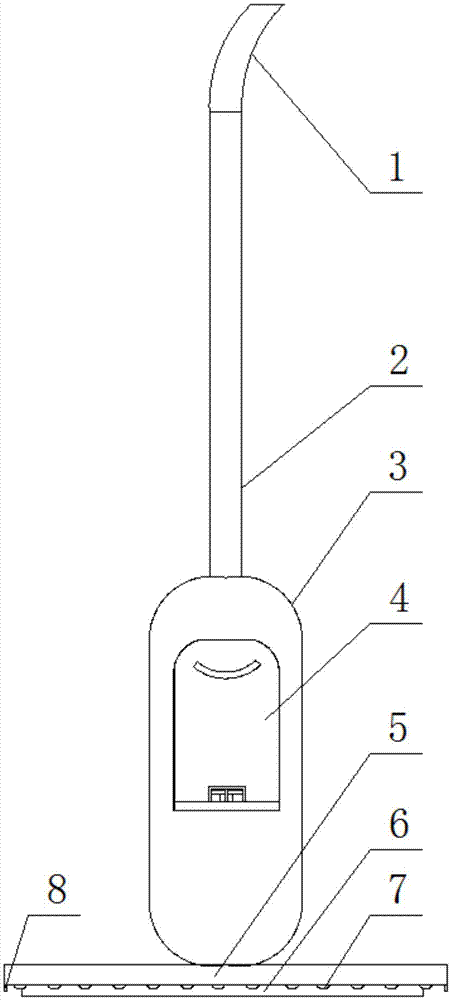

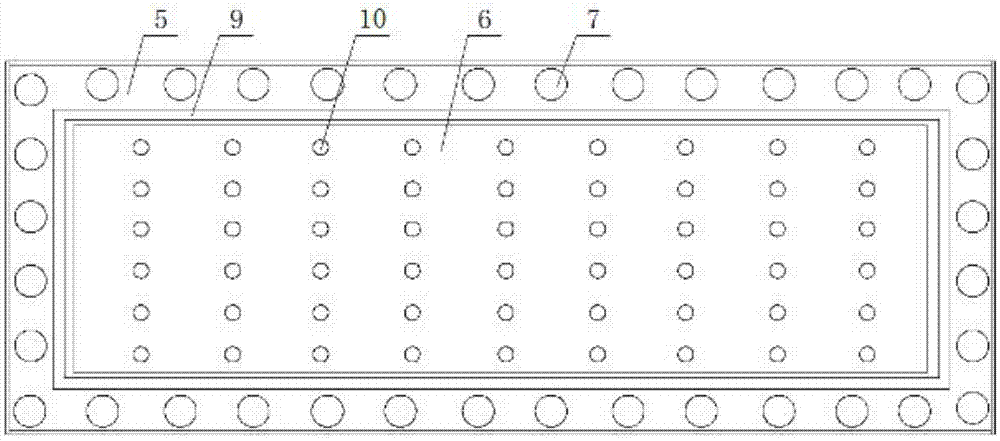

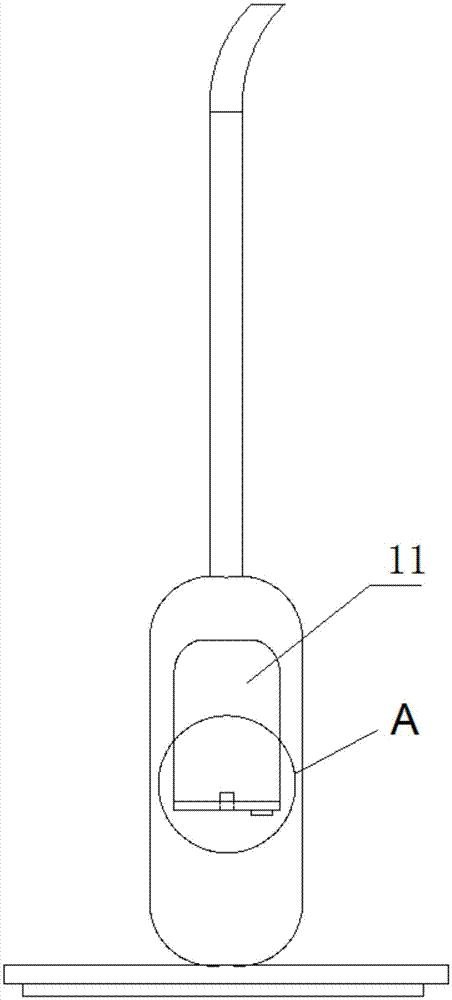

[0030] A steam mop, including a mop rod 2 with a handle 1 on the top, a water tank 4, a steam generator, and a mop 5 with a mop 6 on the bottom. , a water tank mounting seat is installed on the lower end of the mop rod, a drag plate is installed on the lower end of the water tank mounting seat, a water tank is embedded on the water tank mounting seat, and the water outlet of the water tank and the steam generated in the water tank mounting seat The steam outlet of the steam generator is connected to the nozzle hole 10 on the carriage through a pipe, and an ultraviolet lamp and an air outlet 9 are respectively arranged on the bottom outer ring of the carriage, and the air outlet is connected to the water tank Fan connections inside the mount....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com