A kind of lubricating oil and preparation method thereof

A technology for lubricating oil and base oil, applied in the field of lubricating oil and its preparation, can solve the problems of unusable lubricating oil and poor low-temperature fluidity of lubricating oil, and achieve the effects of improving adhesion, good anti-oxidation performance and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

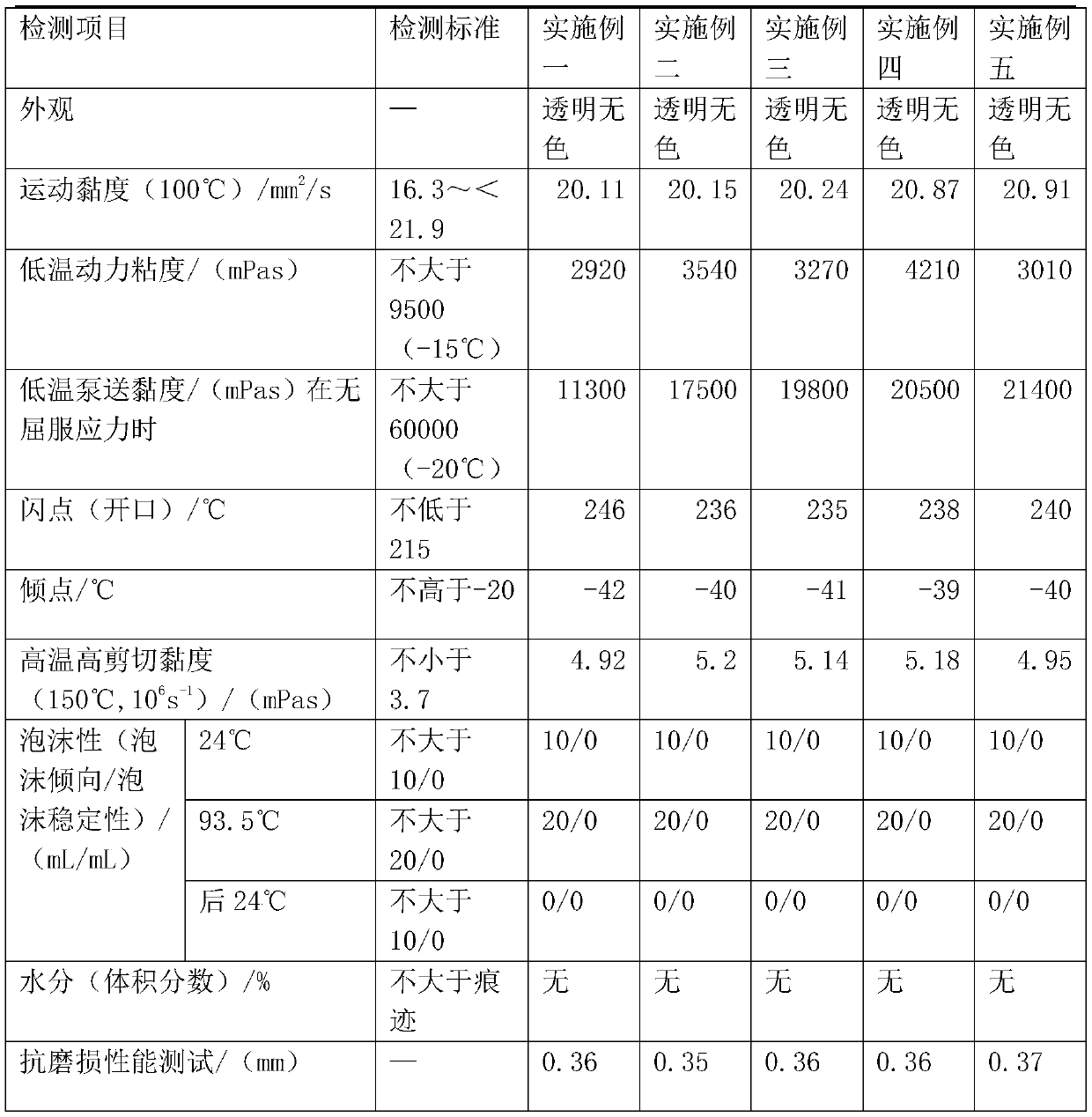

Examples

Embodiment 1

[0034] Embodiment one: a kind of lubricating oil, make according to the following method:

[0035] Preparation of reinforcing agent: Take 68kg of polymethyl methacrylate and heat it to 70°C, add 28kg of ester oil, 5kg of diphenylamine antioxidant containing butyl and octyl groups and 5kg of β-( 3,5-di-tert-butyl-4-hydroxyphenyl) propionate isooctyl alcohol, stirred for 1 hour and mixed to prepare a reinforcing agent.

[0036] Preparation of lubricating oil: Take 65kg of base oil and heat it to 55°C, add 1.5kg of anti-wear functional agent, 2kg of reinforcing agent, 4kg of viscosity index agent, 0.2kg of pour point depressant, 1.5kg of antioxidant and 0.1 kg of antifoaming agent was stirred evenly to obtain lubricating oil.

[0037] Among them, HP202 of LG Chemical is used for polymethyl methacrylate; POE ester oil is used for ester oil; Irganox L57 is used for diphenylamine antioxidant containing butyl and octyl; β-(3,5-di-tert-butyl -4-Hydroxyphenyl) propionate isooctanyl e...

Embodiment 2

[0038] Embodiment two: a kind of lubricating oil, make according to the following method:

[0039] Preparation of reinforcing agent: Take 70kg of polymethyl methacrylate and heat it to 75°C, add 30kg of ester oil, 6kg of diphenylamine antioxidant containing butyl and octyl groups and 6kg of β-( 3,5-di-tert-butyl-4-hydroxyphenyl) propionate isooctanyl, stirred for 1.5h and mixed to prepare a reinforcing agent.

[0040] Preparation of lubricating oil: Take 70kg of base oil and heat it to 60°C, add 2kg of anti-wear functional agent, 4kg of reinforcing agent, 6kg of viscosity index agent, 0.4kg of pour point depressant, 2kg of antioxidant and 0.3kg of anti-wear agent into the base oil in sequence. The foaming agent is stirred evenly to obtain lubricating oil.

[0041] Among them, HP202 of LG Chemical is used for polymethyl methacrylate; POE ester oil is used for ester oil; Irganox L57 is used for diphenylamine antioxidant containing butyl and octyl; β-(3,5-di-tert-butyl -4-Hydro...

Embodiment 3

[0042] Embodiment three: a kind of lubricant is obtained according to the following method:

[0043] Preparation of reinforcing agent: Take 73kg of polymethyl methacrylate and heat it to 80°C, add 32kg of ester oil, 8kg of diphenylamine antioxidant containing butyl and octyl groups and 8kg of β-( 3,5-di-tert-butyl-4-hydroxyphenyl) propionate isooctanyl, stirred for 1.5h and mixed to prepare a reinforcing agent.

[0044] Preparation of lubricating oil: Take 80kg of base oil and heat it to 65°C, add 2.5kg of anti-wear functional agent, 6kg of reinforcing agent, 8kg of viscosity index agent, 0.6kg of pour point depressant, 2.5kg of antioxidant and 0.3 kg of antifoaming agent was stirred evenly to obtain lubricating oil.

[0045]Among them, HP202 of LG Chemical is used for polymethyl methacrylate; POE ester oil is used for ester oil; Irganox L57 is used for diphenylamine antioxidant containing butyl and octyl; β-(3,5-di-tert-butyl -4-Hydroxyphenyl) propionate isooctanyl ester ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com