Preparation method of matte solid watercolor paint

A watercolor and solid technology, applied in the direction of polyether paint, starch paint, art paint, etc., can solve the problems of high equipment requirements, long production cycle, complex process, etc., and achieve low input cost, high production efficiency, and good water solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

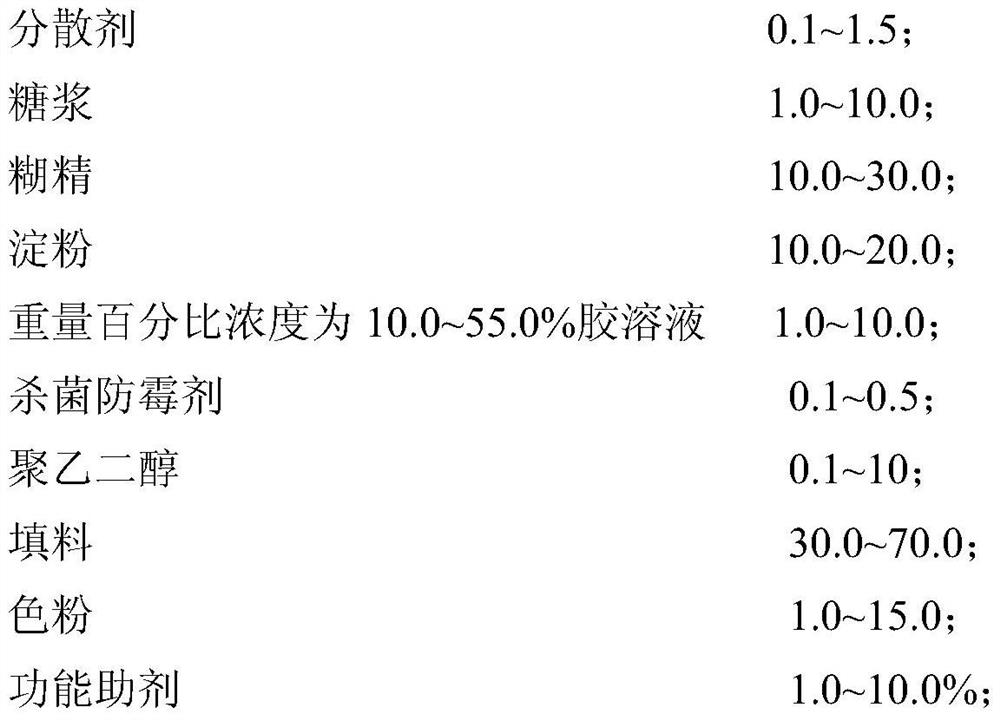

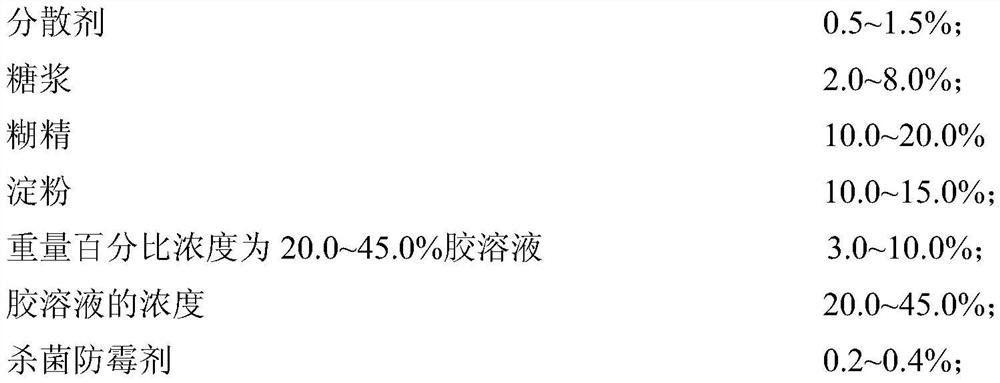

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, a matte solid watercolor paint, its components are: hexenyl bis-stearamide 0.7%, white honey 4%, dextrin 16%, corn starch 12%, 6% peach gum solution of 30% by weight , 0.3% sodium benzoate, 5% polyethylene glycol with a molecular weight of 4000, 18% kaolin, 30% ground calcium carbonate, 6% phthalocyanine blue BGS toner, and 2% sodium dodecylbenzenesulfonate.

[0047] The preparation method of the matte solid watercolor paint of the present embodiment is: comprising the following steps:

[0048] (1) take by weighing peach gum and add in water and stir until completely dissolved to make 30% peach gum solution;

[0049] (2) take by weighing peach gum solution in container, then add hexenyl bis-stearamide, honey, white dextrin, corn starch, sodium benzoate, polyethylene glycol, kaolin, heavy carbonic acid in order in the container respectively Calcium, phthalocyanine blue BGS toner, sodium dodecylbenzenesulfonate, stir well by hand;

[0050] (3) in the above...

Embodiment 2

[0052] Example 2, the components of the matte solid watercolor paint are: hexenyl bis-stearamide 0.7%, honey 6.0%, yellow dextrin 10%, corn starch 12%, 30% by weight gum arabic solution 6%, benzene 0.3% of sodium formate, 5% of polyethylene glycol with molecular weight of 4000, 10% of kaolin, 20% of heavy calcium carbonate, 22% of light calcium carbonate, 6% of 3132 bright red powder, 2% of sodium dodecylbenzenesulfonate.

[0053] The preparation method of the matte solid watercolor paint of the present embodiment is: comprising the following steps:

[0054] (1) Weigh the gum arabic, add it in water and stir until it is completely dissolved to make a 30% gum arabic solution;

[0055] (2) Weigh the gum arabic solution obtained in step (1) in a container, then add hexenyl bis-stearamide, honey, yellow dextrin, cornstarch, sodium benzoate, polyethylene to the container in sequence. Diol, kaolin, heavy calcium carbonate, light calcium carbonate, 3132 bright red powder, sodium dod...

Embodiment 3

[0058] Example 3, the components of the matte solid watercolor paint are: ammonium polyacrylate 1.5%, honey 3.4%, white dextrin 10%, tapioca starch 10%, peach gum 1.0% by weight 30%, 2-methyl -4-isothiazolin-3-one (MI) 0.1%, molecular weight 2000 polyethylene glycol 2%, heavy calcium carbonate 50%, light calcium carbonate 10%, barium sulfate 10%, black toner 1% , Sodium tripolyphosphate 1%.

[0059] The preparation method of the matte solid watercolor paint of the present embodiment is: comprising the following steps:

[0060] (1) take by weighing peach gum and add in water and stir until completely dissolved to make 30% peach gum solution;

[0061] (2) take by weighing the prepared peach gum solution of step (1) in a container, then add polyacrylic acid ammonium salt, honey, white dextrin, tapioca starch, 2-methyl-4-isopropyl acrylate in sequence in the container respectively Thiazolin-3-one (MI), polyethylene glycol, heavy calcium carbonate, light calcium carbonate, barium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com