Steel pipe composite pile foundation applicable to deep water and coral reef geology

A composite pile and coral reef technology, applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of low lateral friction resistance, difficulty in meeting bearing capacity requirements, low efficiency, etc., to reduce the amount of steel bars and construction risks. and cost, the effect of increasing the bearing capacity of the pile foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

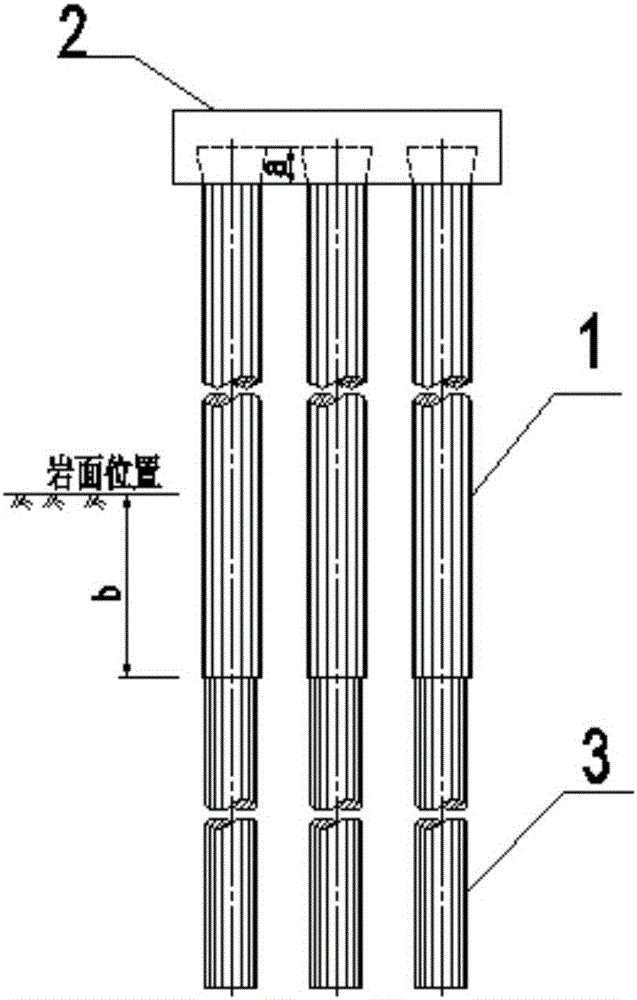

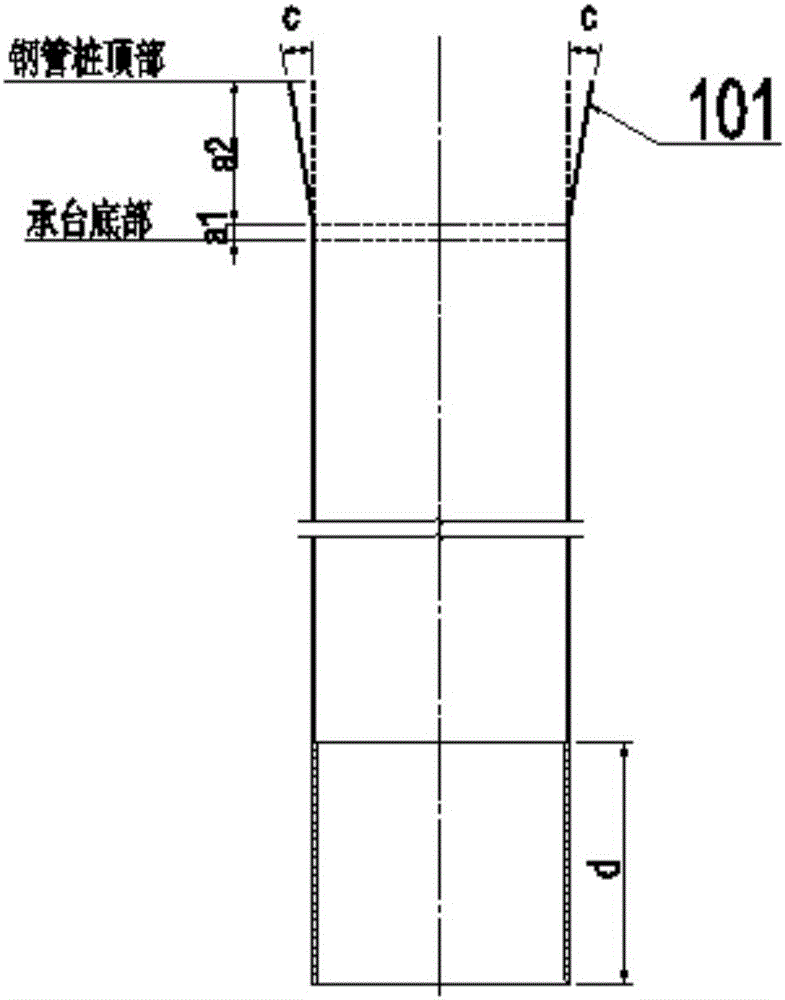

[0036] A structural form of steel pipe composite pile foundation suitable for deep water and coral reef geological conditions, such as figure 1 As shown, it consists of three parts: steel casing 1, cap 2, and reinforced concrete pile body 3. It is characterized in that steel casing 1 participates in the horizontal bearing of the pile foundation, and vertically bears the steel casing and the bored pile. The most important thing to bear is the concrete pile inside the steel casing.

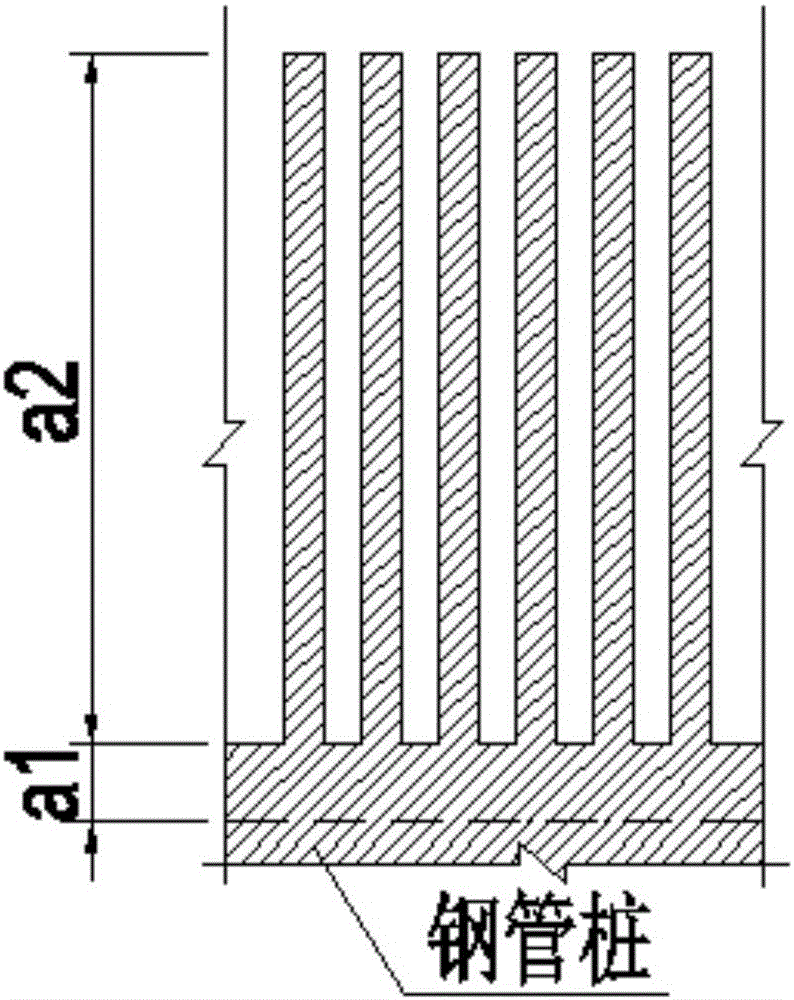

[0037] In order to ensure that the steel casing 1 and the reinforced concrete part are jointly stressed, the upper end of the outer steel casing 1 and the reinforced concrete pile body 3 goes deep into the cap 2, and its depth is a, and the value of a is generally equal to the cap 2 half of the height to ensure that the upper end is embedded. The length of the steel casing 1 is shorter than that of reinforced concrete. The length b of the steel casing 1 deep into the rock surface is determined acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com