Assembly type concrete slotting shear wall

A concrete and prefabricated technology, applied to walls, protective buildings/shelters, building components, etc., can solve the problems of small deformation capacity, low energy consumption capacity, and increased casualties, so as to increase deformation capacity and ductility, The effect of increasing the lateral stiffness and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

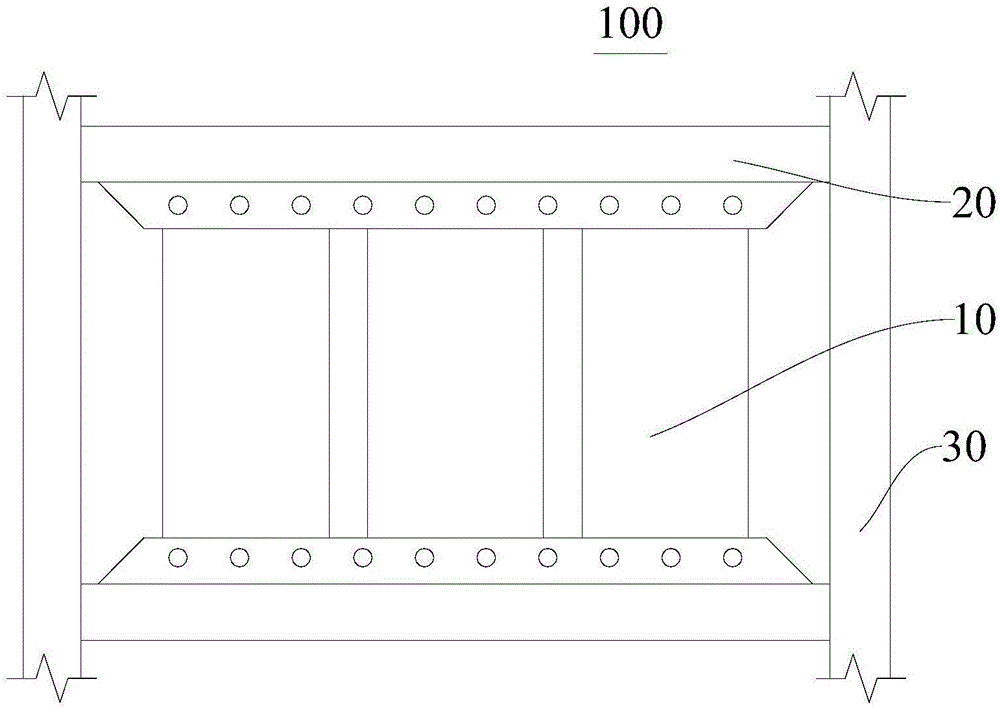

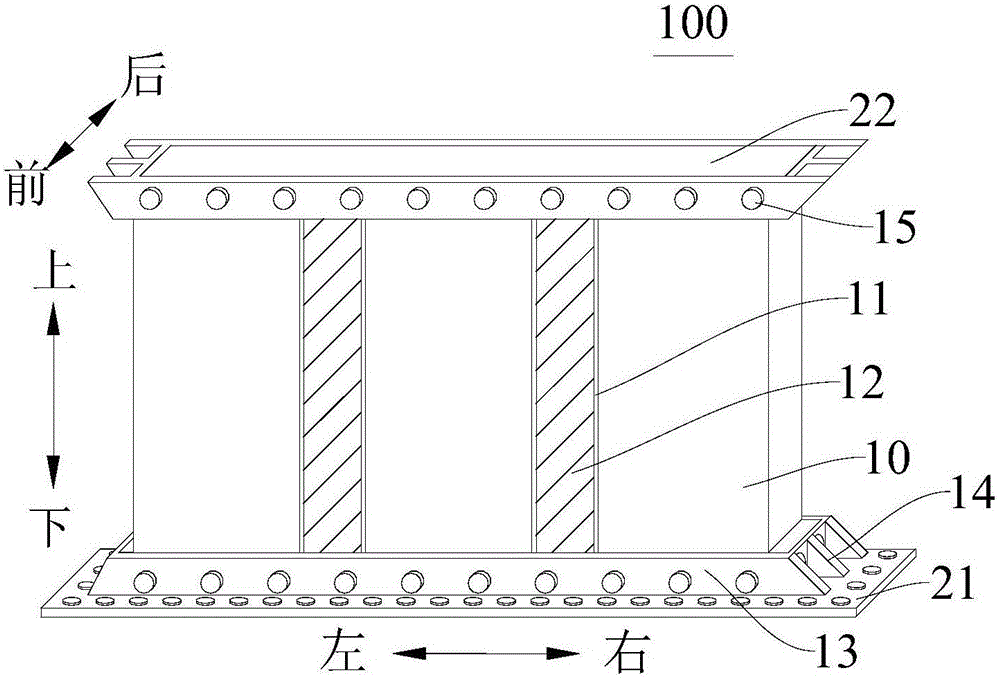

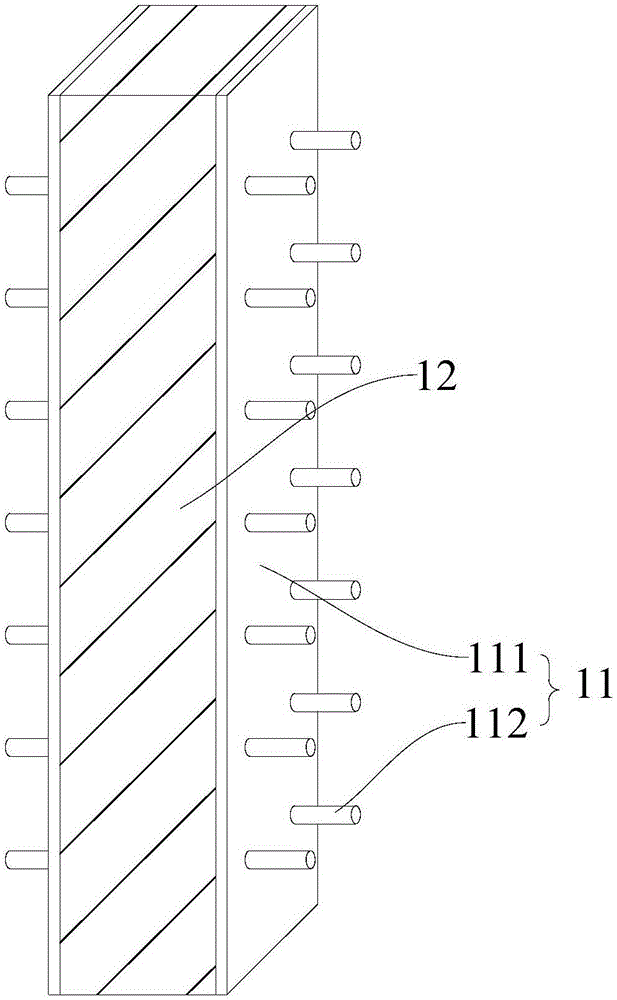

[0100] Such as Figure 1 to Figure 4 shown, combined with Figure 7, the prefabricated concrete slotted shear wall 100 includes: at least one concrete prefabricated wall panel 10, frame beams 20 and frame columns 30, the frame beams 20 include two and are arranged at intervals along the upper and lower directions, and the frame columns 30 include two and They are respectively arranged on both sides of the frame beam 20, and the upper and lower ends of each frame column 30 are respectively connected with the frame beam 20 located above and below. The frame beams 20 are connected, and the two frame columns 30 are respectively located on both sides of the precast concrete wall panel 10 , and the precast concrete wall panel 10 is provided with a plurality of first damping joints 110 arranged at intervals.

[0101] Each first damping joint 110 runs through the thickness direction of the concrete prefabricated wall panel 10 respectively, and viscoelastic energy-dissipating material...

Embodiment 2

[0107] Such as figure 1 , Figure 5 and Figure 6 shown, combined with Figure 8 , the prefabricated concrete slotted shear wall 100 includes: at least one concrete prefabricated wall panel 10, frame beams 20 and frame columns 30, the frame beams 20 include two and are arranged at intervals along the upper and lower directions, and the frame columns 30 include two and They are respectively arranged on both sides of the frame beam 20, and the upper and lower ends of each frame column 30 are respectively connected with the frame beam 20 located above and below. The frame beams 20 are connected, and the two frame columns 30 are respectively located on both sides of the concrete prefabricated wall panel 10. The concrete prefabricated wall panel 10 is provided with a plurality of spaced apart first damping joints 110, and each first damping joint 110 Respectively penetrate along the thickness direction of the concrete prefabricated wall panel 10, and each first damping joint 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com