An outrigger oil circuit system

An oil circuit system and oil circuit technology, which is applied in the direction of fluid pressure actuation system components, lifting devices, fluid pressure actuation devices, etc., can solve the problems that affect the use of orders, large force, small hose bending radius, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

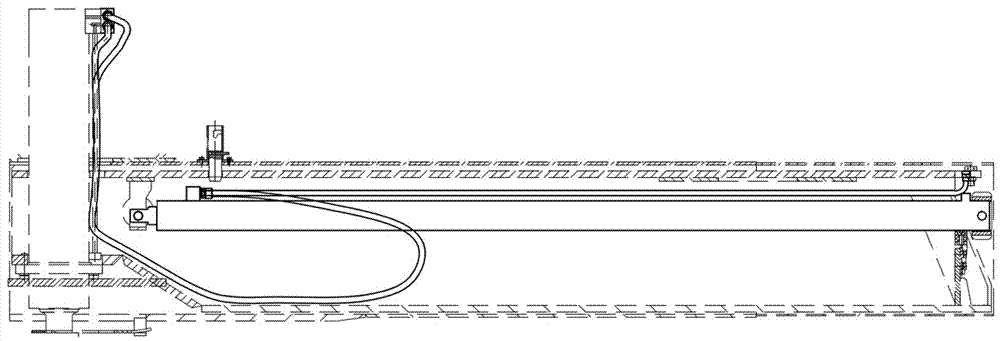

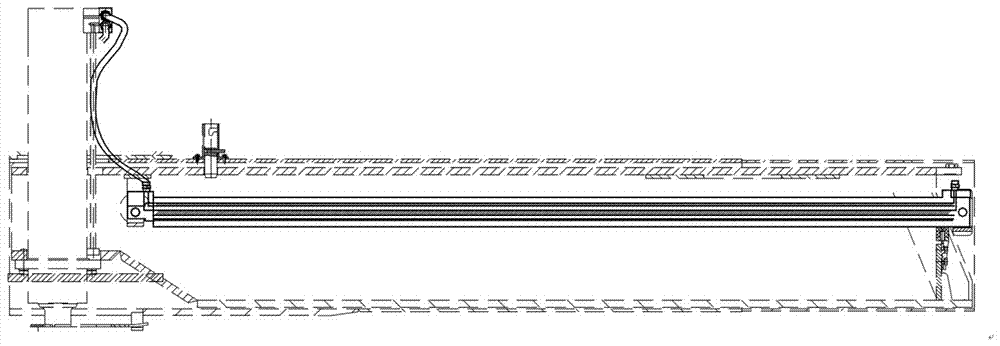

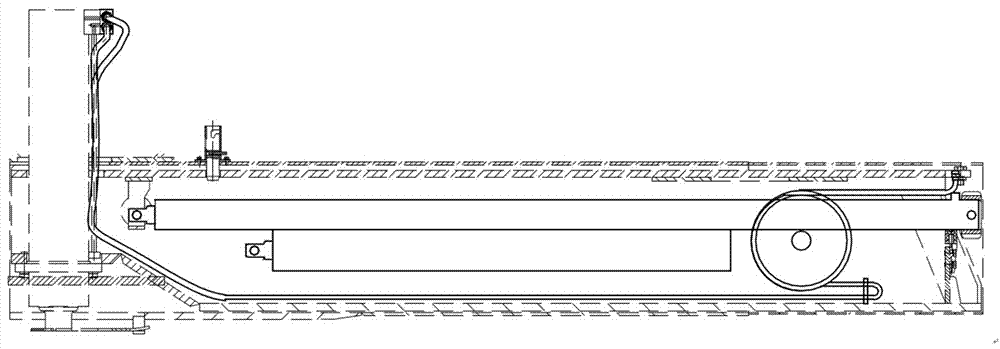

[0034] The invention provides a horizontal outrigger oil circuit system, which can especially be used to guide the direction of the hydraulic oil circuit without an oil cylinder when the manual horizontal outrigger box is telescopic, and is suitable for introducing the oil circuit into other implements through the horizontal telescopic outrigger box. The equipment of the mechanism, such as the truck-mounted crane transporter, introduces the power oil source into the vertical outrigger hydraulic cylinder through the horizontal outrigger box.

[0035] The system of the present invention includes a movable outrigger box 1 and a fixed outrigger box 19, the movable outrigger box 1 is sleeved at one end inside the fixed outrigger box 19, and is attached to the oil circuit of the movable outrigger box 1 and the fixed outrigger box 19 The assembly introduces pressurized oil from an external source into the vertical cylinder. In light construction machinery and equipment, both ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com