Combined bearing and rotating shaft device using combined bearing

A combined bearing and shaft device technology, applied in the direction of bearings, bearing elements, shafts and bearings, etc., can solve the problems of hard to find woodworking end mills and high speed requirements, and achieve the effect of increasing stability and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

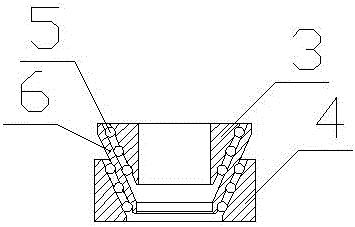

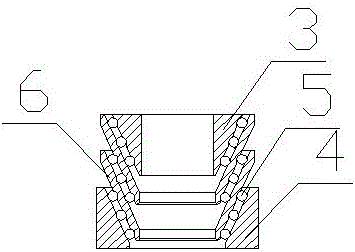

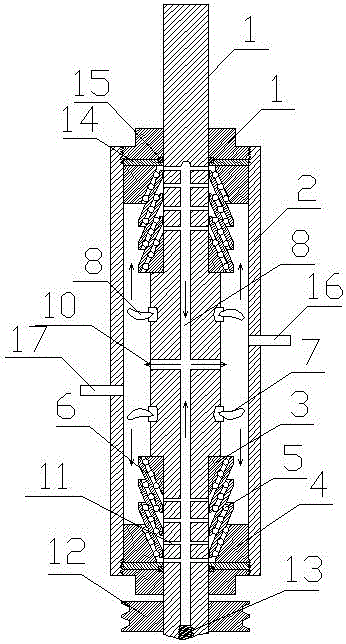

[0021] A rotating shaft device using the above-mentioned combined bearing, comprising; The main oil hole 18 is arranged in the axial direction of the axis of the rotating shaft 1. Two sets of combined bearings are arranged on the shaft body of the rotating shaft 1. The first impeller 7 and the second impeller 8 are arranged between the two sets of combined bearings. The first impeller 7 and the second The radial oil hole 10 communicating with the main oil hole 18 is arranged between the impellers 8, and the radial branch oil hole 11 communicating with the main oil hole 18 is respectively arranged on the shaft body where two sets of combined bearings are installed, and the shaft sleeve 2 Nuts 19 for fixing the composite bearing are respectively arranged at both ends of the composite bearing; the radial oil branch holes 11 are all arranged at the interval where the composite bearing is provided with rolling elements 5, and the shaft sleeve 2 is provided with an oil inlet hole 16 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap