A thermal baking experimental device for testing the reaction level of the shock plate detonator to high temperature stimulation

An impact sheet detonator and stimulation reaction technology, applied in weapon accessories, fuzes, offensive equipment, etc., can solve problems such as the influence of the thermal response characteristics of reactive grade explosives, reduce the interference factors of uneven heating, and improve the test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

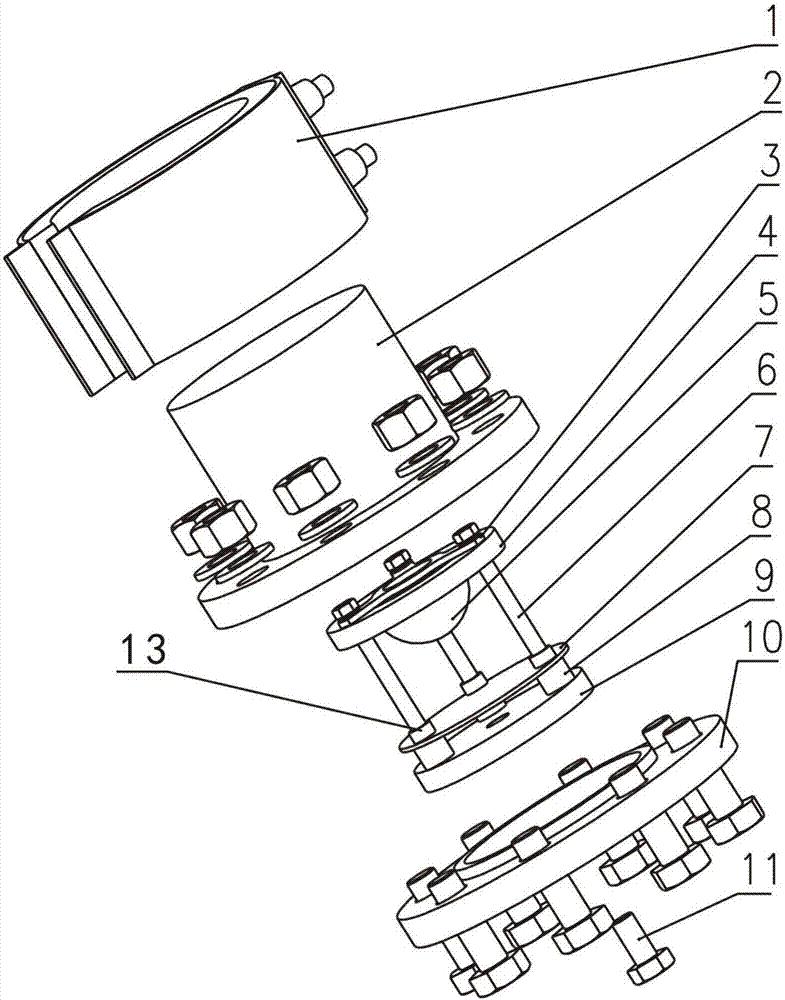

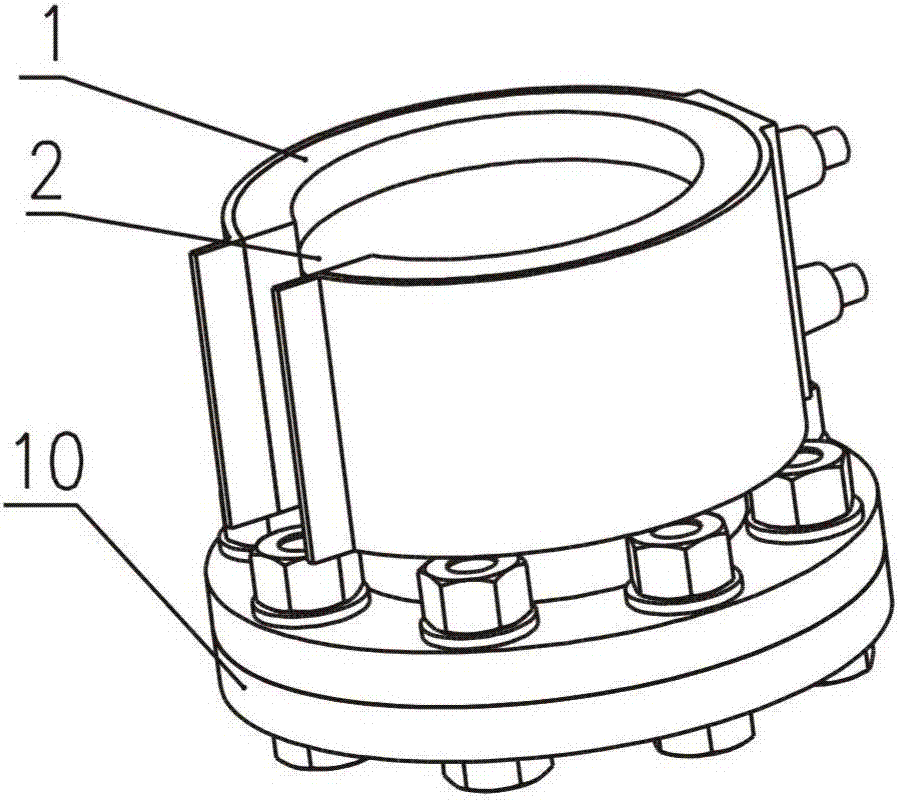

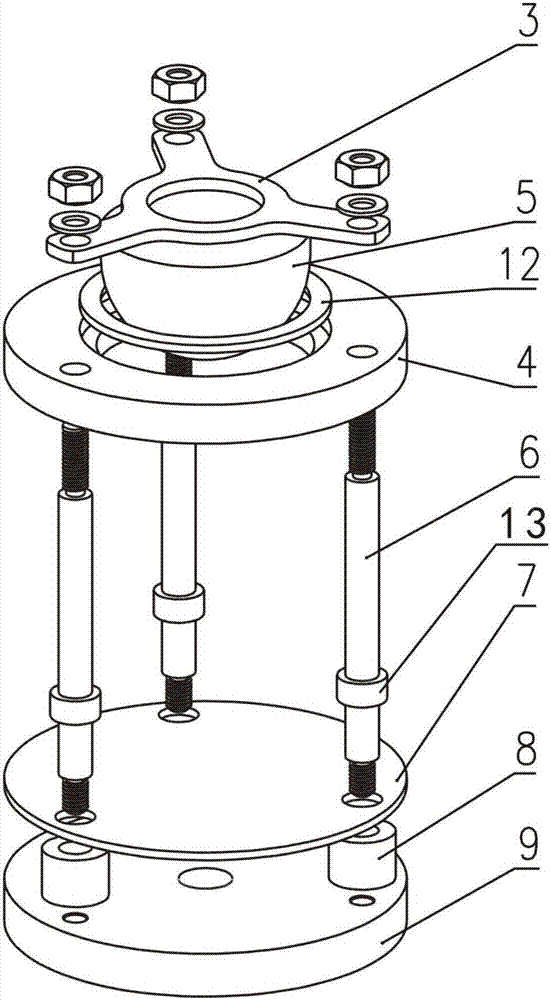

[0017] Such as figure 1 , figure 2 with image 3 As shown, the thermal roasting experimental device for testing the shock level of the shock blaster detonator according to the present invention is used to perform a thermal roasting experiment on the shock blaster detonator 5, including an electric heating ring 1, a cylinder body 2, a cylinder cover 10, a test bracket and The test plate 7 is used to withstand the impact of the shock plate detonator after the explosion of the test. The electric heating ring 1 is set outside the cylinder body 2 and used to heat the cylinder body 2. The cylinder cover 10 is installed on one end of the cylinder body 2. The test The bracket is installed in the cylinder body 2. The test bracket includes a gland 3, an installation cover 4, a support rod 6, a bushing 8, a base 9 and a support gasket 12, and the two ends of a plurality of support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com