An improved elastic earphone wire

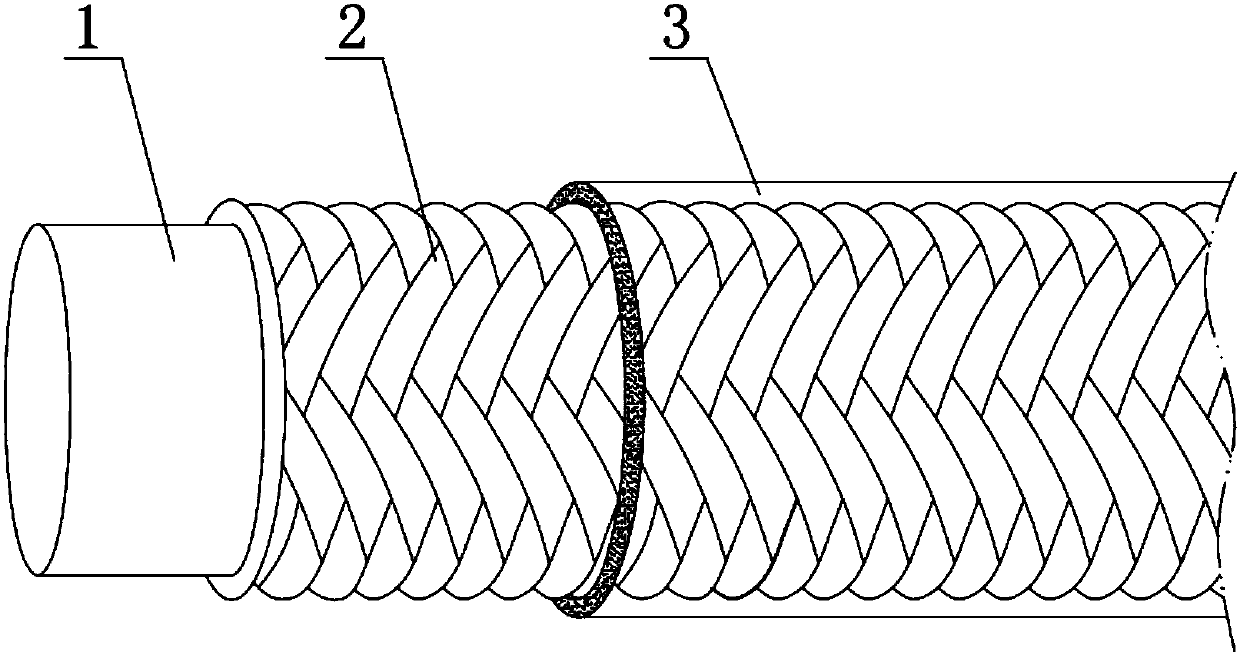

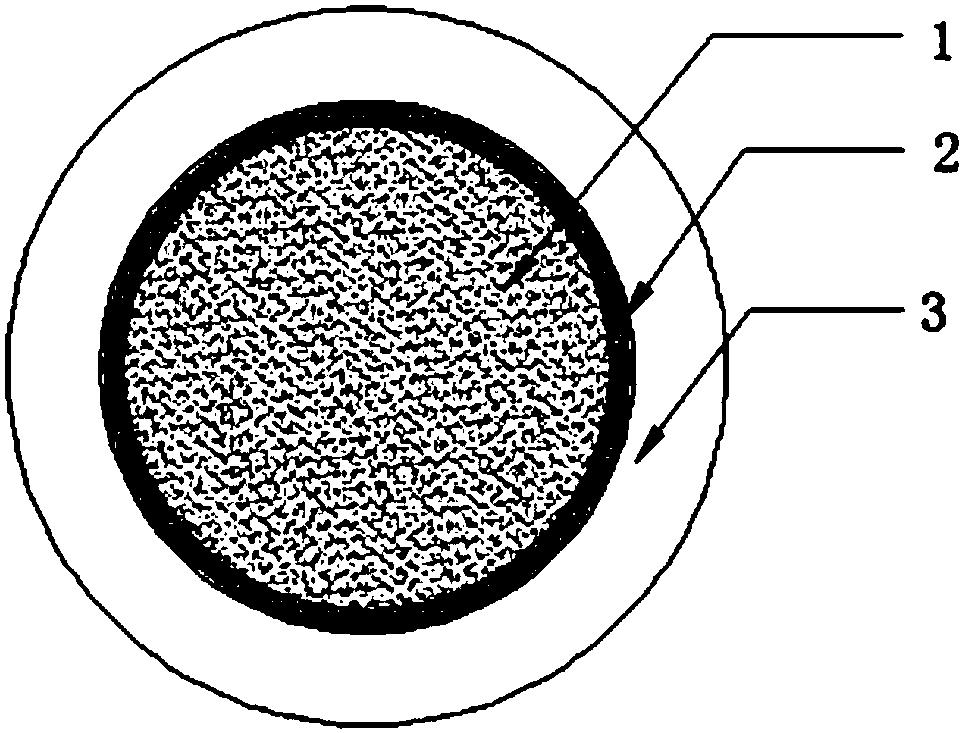

An improved technology for headphone wires, which is applied in the field of high-elastic bonding plastic materials, can solve the problems of being unable to meet dynamic occasions, being unable to be used for headphone wires, and poor repeated bending performance, and achieving excellent elasticity, long stretching length, and excellent The effect of scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

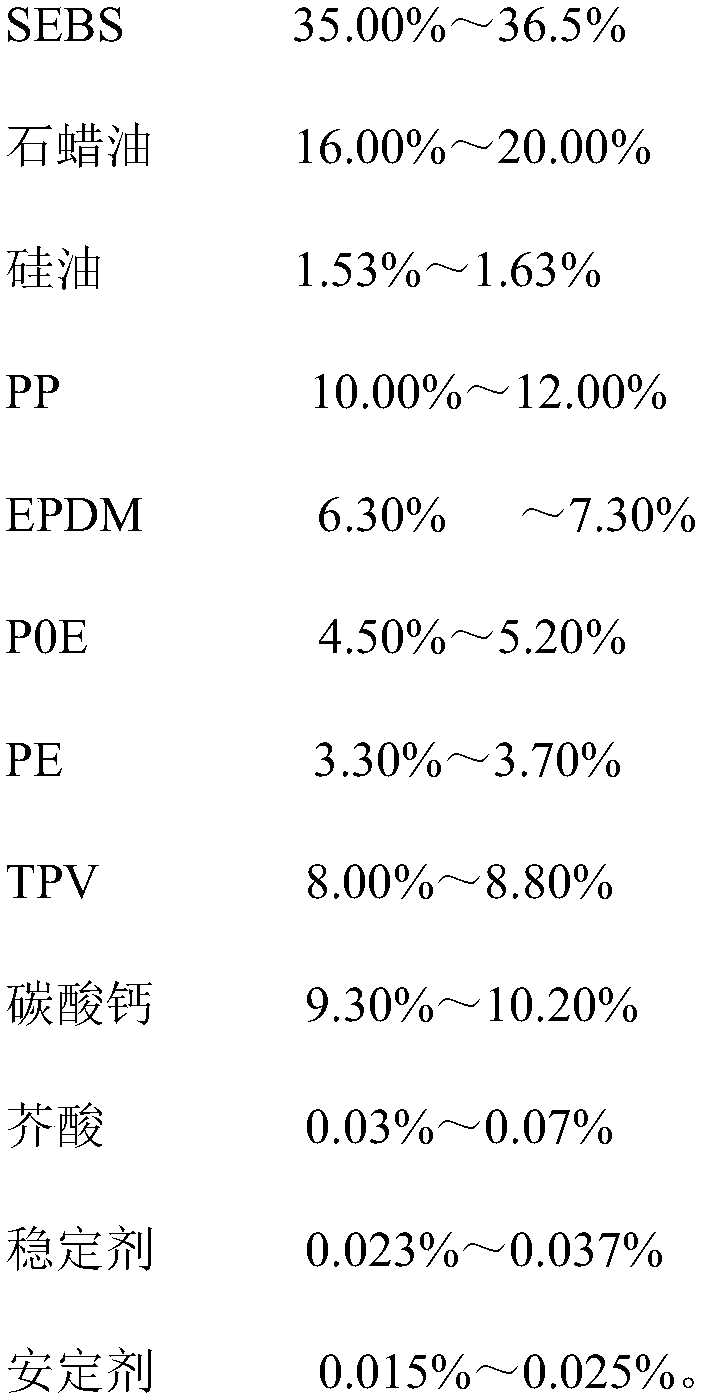

Embodiment 1

[0028] The elastic core wire of the improved elastic earphone wire is made of the following components in weight percentage: 36.00% for SEBS, 18.00% for paraffin oil, 1.60% for silicone oil, 11.00% for PP, 6.80% for EPDM, and 4.80% for P0E %, PE is 3.50%, TPV is 8.40%, calcium carbonate is 9.80%, erucic acid is 0.05%, stabilizer is 0.030%, and stabilizer is 0.020%. Wherein, the stabilizer is a mixture of antioxidant 168 and antioxidant 1024; the stabilizer is a mixture of dibutyltin dilaurate and dibutyltin maleate, wherein dibutyltin dilaurate and dibutyltin maleate The weight percentage of dibutyltin dilaurate in the mixture is 20%-80%.

Embodiment 2

[0030] The elastic core wire of the improved elastic earphone wire is made of the following components by weight percentage: 35% for SEBS, 19.1% for paraffin oil, 1.53% for silicone oil, 12% for PP, 6.3% for EPDM, and 4.5% for P0E %, PE is 3.3%, TPV is 8%, calcium carbonate is 10.2%, erucic acid is 0.03%, stabilizer is 0.023%, and stabilizer is 0.015%. Wherein, the stabilizer is a mixture of antioxidant 1010 and antioxidant 168; the stabilizer is a mixture of dibutyltin dilaurate and dibutyltin maleate, wherein dibutyltin dilaurate and dibutyltin maleate The weight percentage of dibutyltin dilaurate in the mixture is 20%-80%.

Embodiment 3

[0032] The elastic core wire of the improved elastic earphone wire is made of the following components in weight percentage: 35.5% for SEBS, 20% for paraffin oil, 1.60% for silicone oil, 10.5% for PP, 6.80% for EPDM, and 4.6% for P0E %, PE is 3.40%, TPV is 8.20%, calcium carbonate is 9.30%, erucic acid is 0.05%, stabilizer is 0.028%, and stabilizer is 0.019%. Wherein, the stabilizer is a mixture of antioxidant 1076 and antioxidant 1024; the stabilizer is a mixture of dibutyltin dilaurate and dibutyltin maleate, wherein dibutyltin dilaurate and dibutyltin maleate The weight percentage of dibutyltin dilaurate in the mixture is 20%-80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com