Hydraulic pump installation structure

A mounting structure, hydraulic pump technology, applied to parts, pump elements, transmissions, etc. of pumping devices used for elastic fluids, can solve the problem of not being able to fully suppress the displacement of the pump casing, not being easy to set the thickness of the supporting member, Shape and other problems, to achieve the effect of suppressing displacement, suppressing the number of parts, and suppressing relative displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

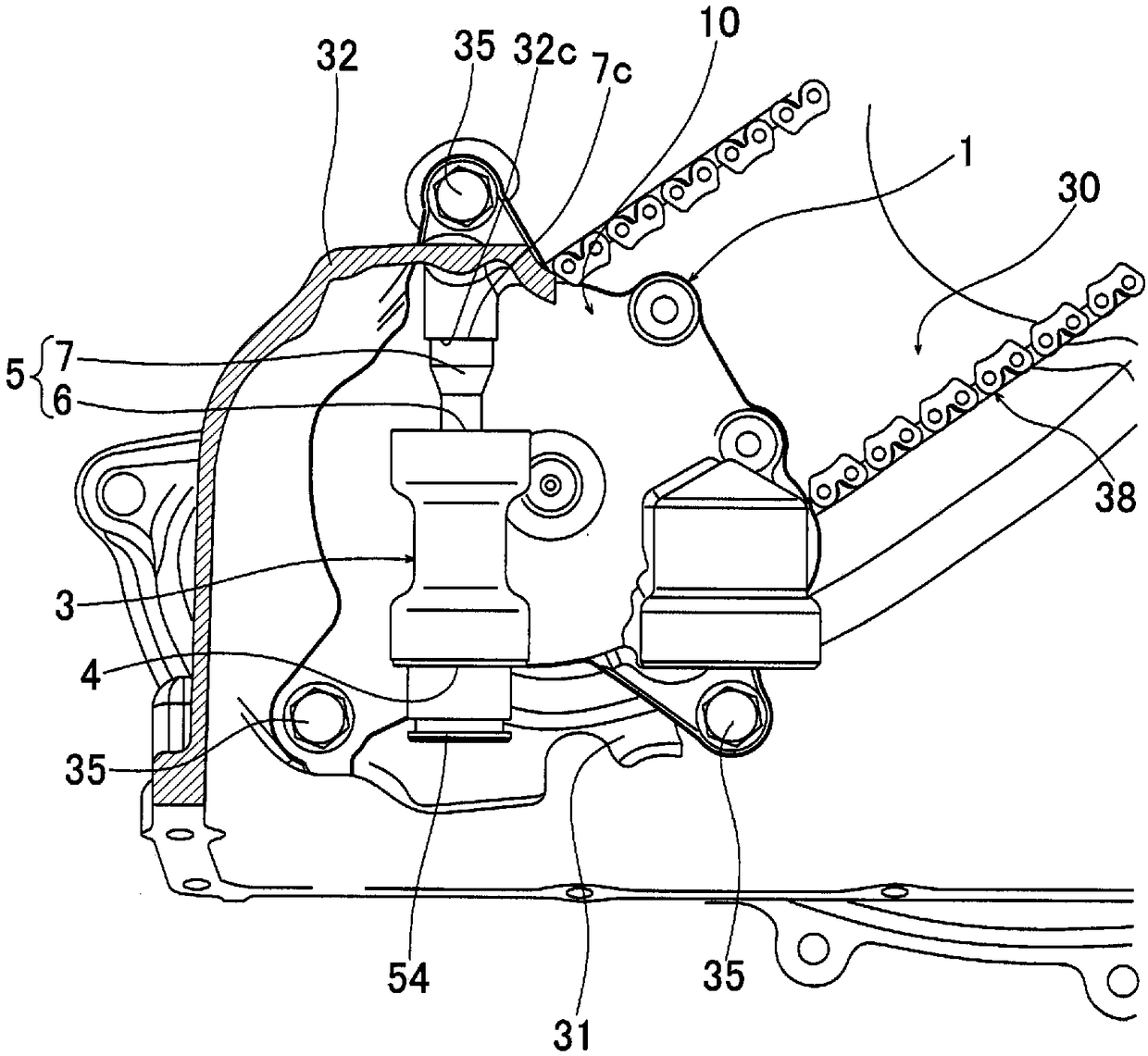

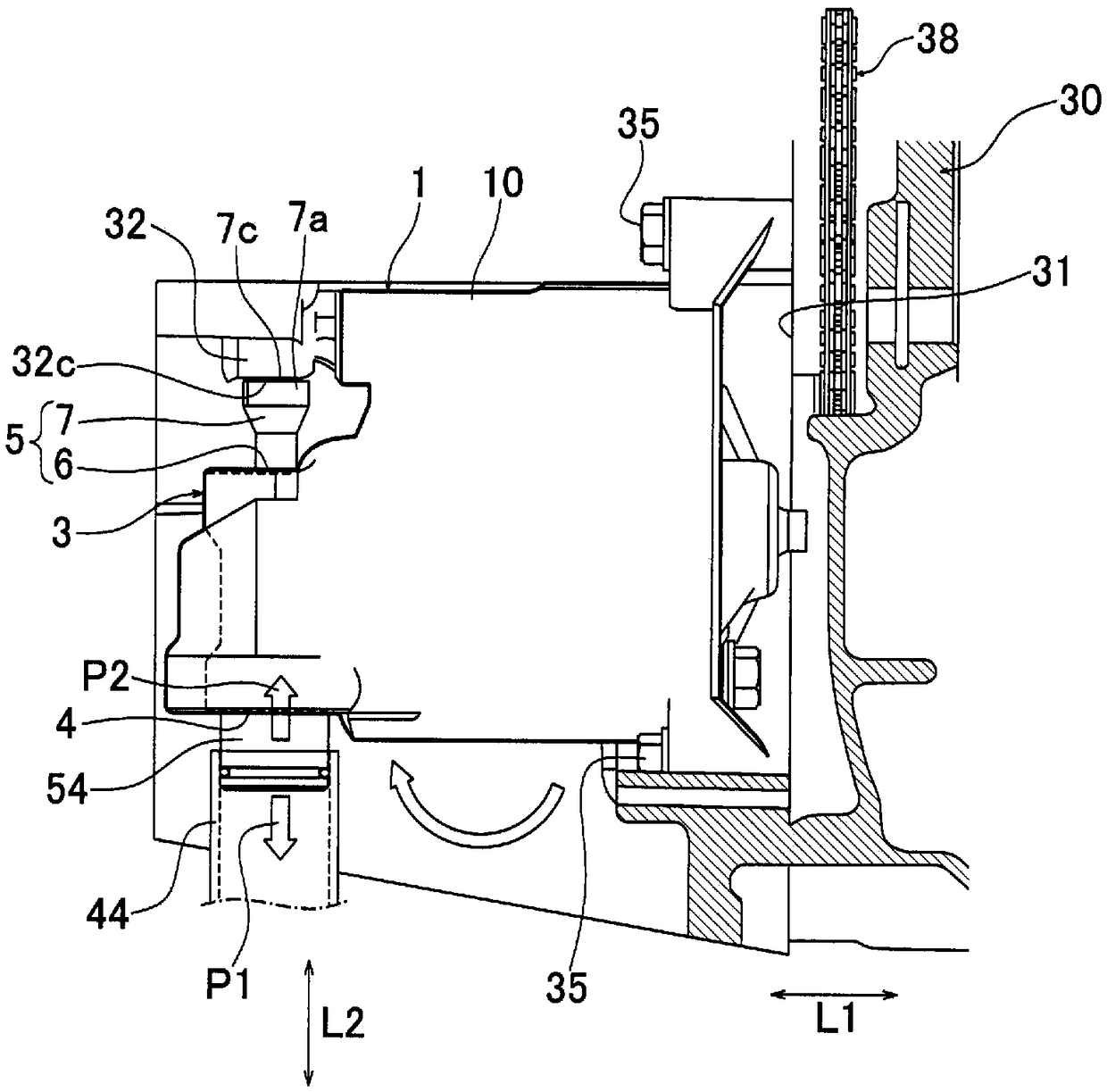

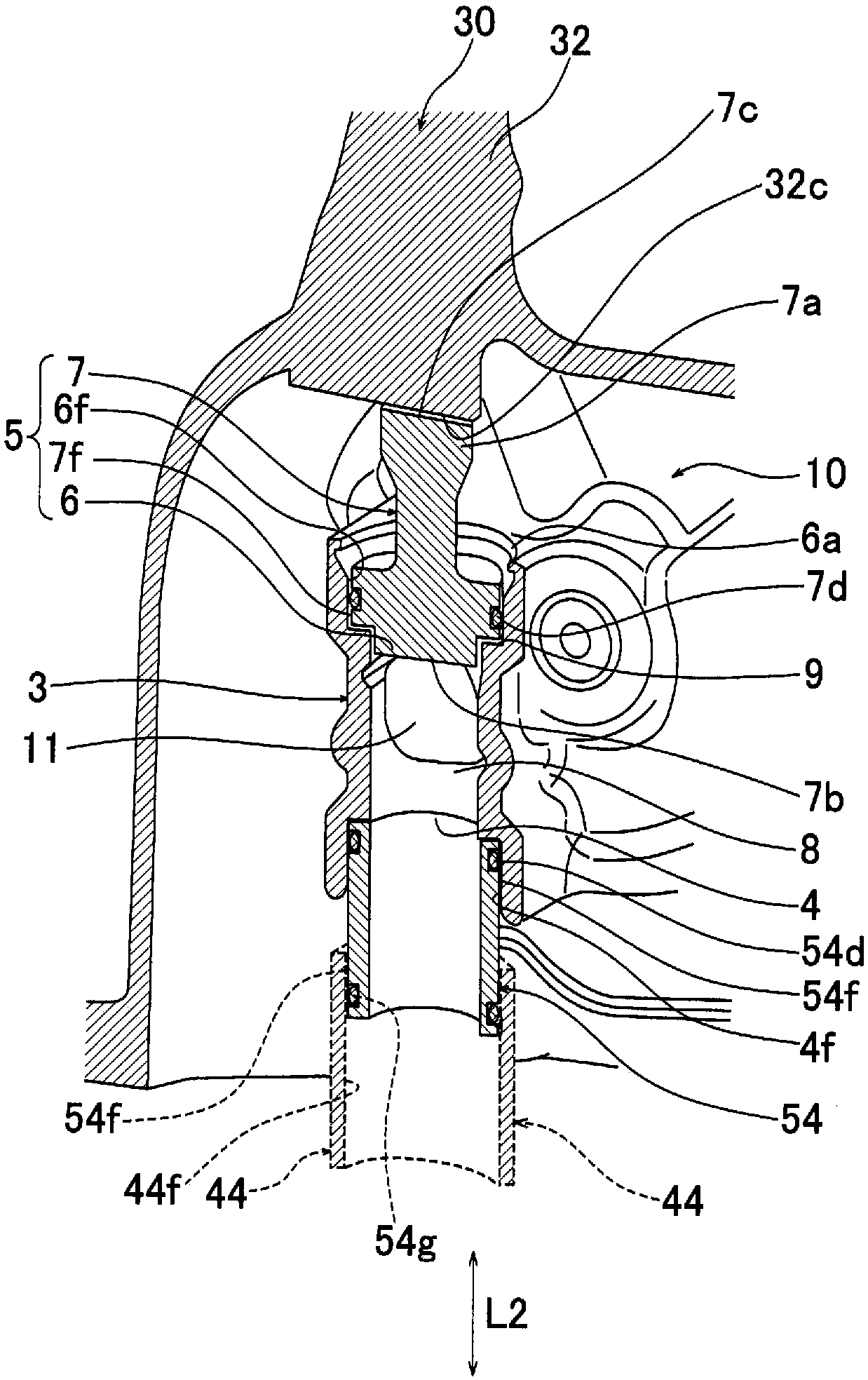

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 and figure 2 It is a figure which shows the hydraulic pump 1 mounted|worn in the mounting structure of one embodiment of this invention, figure 1 is the main view, figure 2 is a side view. and, image 3 It is a perspective view showing a part of the pump housing 10 of the hydraulic pump 1 and the transmission housing 30 of the transmission in cross section.

[0024] The mounting structure of the hydraulic pump 1 in the present embodiment is a mounting structure of the hydraulic pump 1 for supplying hydraulic pressure to a hydraulic control device (control body) included in a transmission (the overall illustration is omitted). Such as figure 1 and figure 2 As shown, the installation structure has: a substantially planar installation surface 31, which is used to install the hydraulic pump 1 on the transmission case 30; the pump housing 10 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com