Oil distribution element

A hollow, rotor shaft technology, used in electrical components, electric components, electromechanical devices, etc., can solve problems such as too small cross-section of pipelines, increase in moving mass, and reduce volume requirements, and achieve increased weight per unit power, large output, Efficient cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

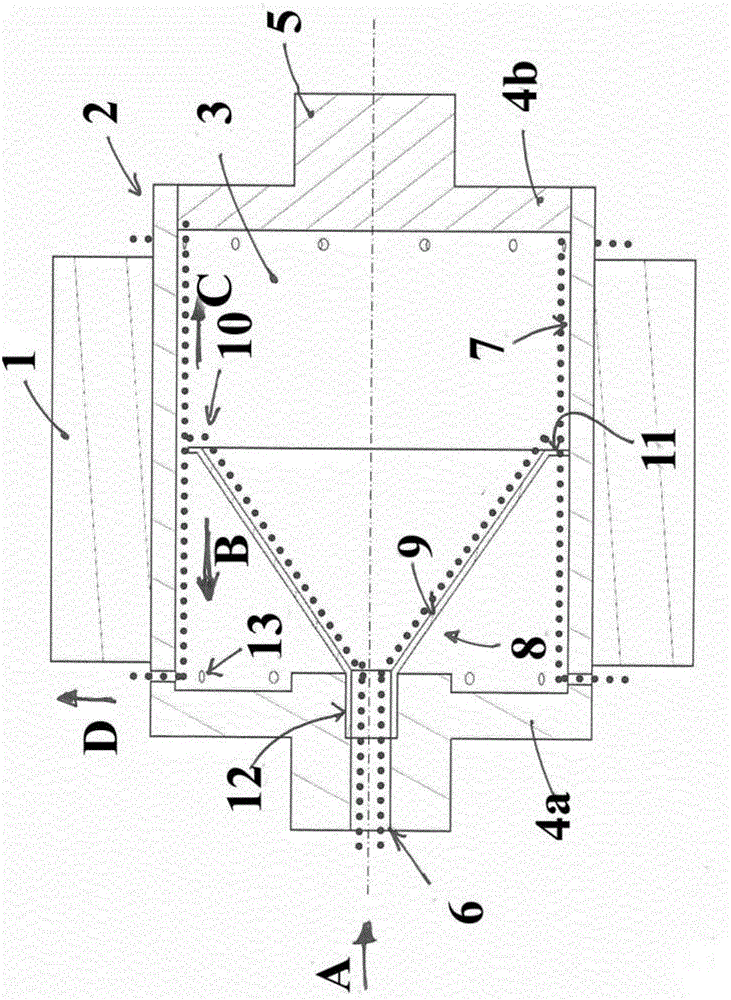

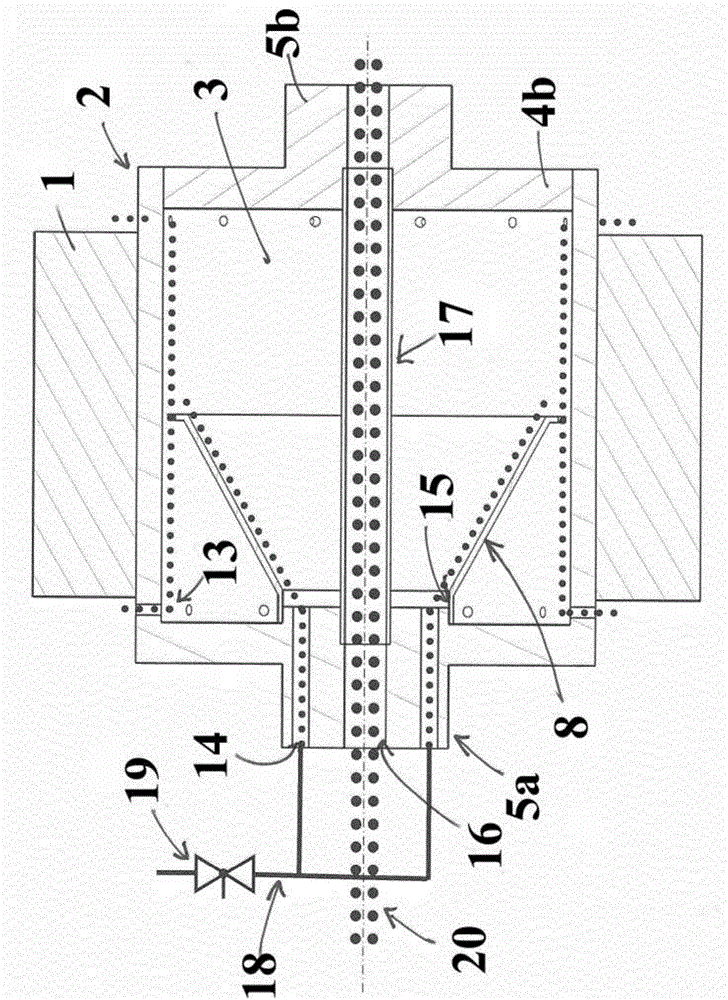

[0029] exist figure 1 , firstly shows a rotor for an electric machine, in particular for an asynchronous or permanent magnet synchronous machine, which has a hollow rotor shaft equipped with a laminated core 1 . The hollow rotor shaft is formed by a cylindrical barrel 2 which surrounds a shaft cavity 3 and is closed on both sides by surface flanges 4 . In this example, one surface flange 4 a is formed on the cylindrical barrel 2 and the other flat flange 4 b is fitted into the cylindrical barrel 2 . In each case, at both surface flanges 4 there is provided a journal 5 which is formed on or attached as a separate component. In one of the journals 5 there is provided an inlet 6 through which a cooling fluid (shown as a dot) enters the shaft chamber 3 in the direction of arrow A and reaches the inner surface 7 of the cylindrical barrel.

[0030] In the shaft cavity 3 is arranged a distribution element 8 which receives the cooling fluid entering through the inlet 6 and passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com