Single-arm type multi-dimensional movement mixer

A mixer and multi-dimensional technology, applied in the direction of mixers, mixers with rotating containers, mixer accessories, etc., can solve the problems of low mixing uniformity, poor safety performance, cross-contamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

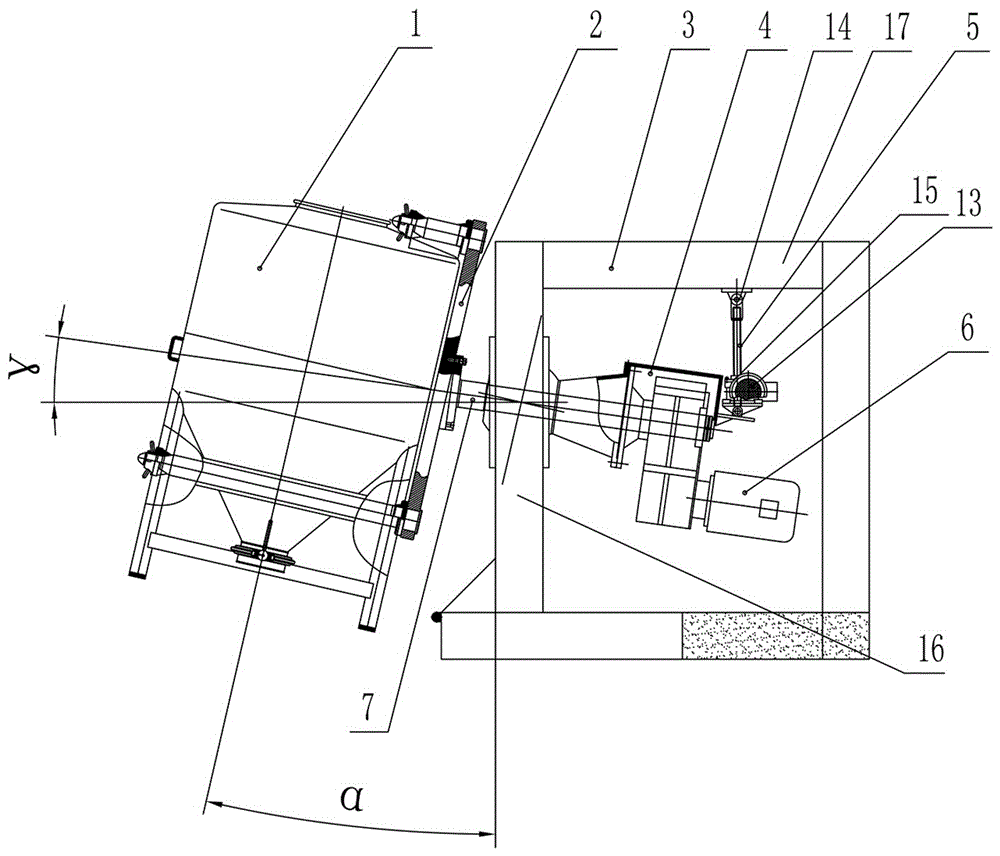

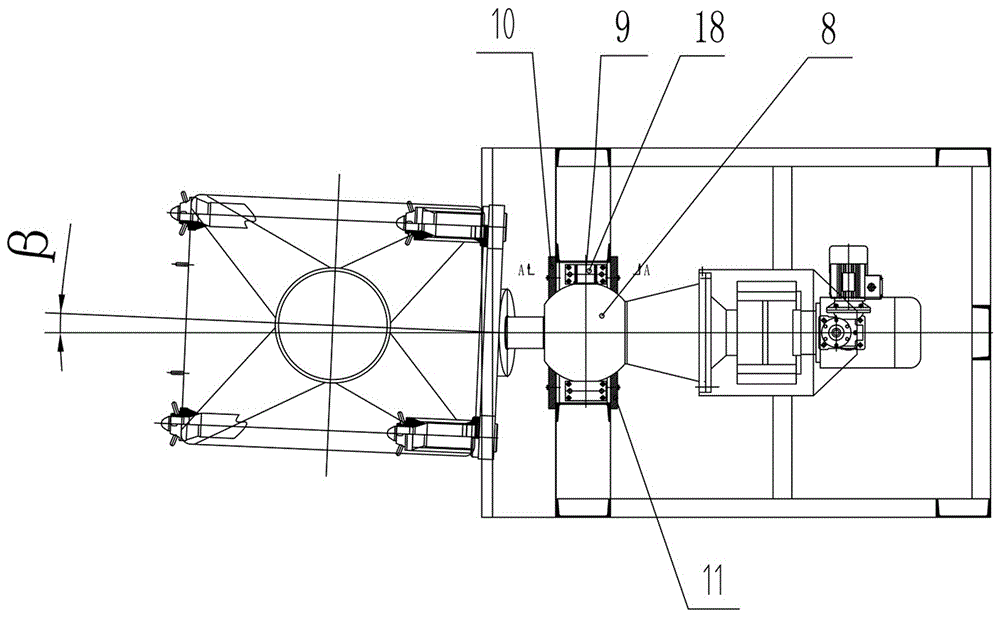

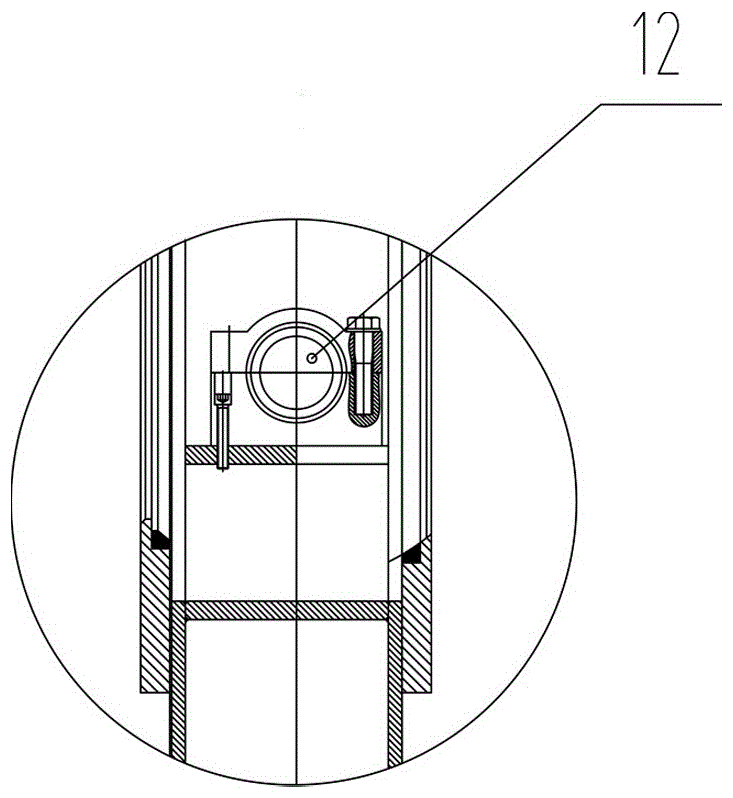

[0013] like figure 1 , figure 2 , image 3 As shown, a single-arm multi-dimensional motion mixer in this embodiment includes a mixing tank 1 and a mixer transmission mechanism capable of lifting movement. The transmission mechanism includes a frame 3, a speed reducer 6, a transmission spindle 7 of the speed reducer, Drive the main shaft support and the screw lifter, and the mixing tank 1 is installed on the mixing tank support 2 . The supporting part of the transmission spindle is a hollow sphere 8, which is movably placed in the sphere seat 9 in the frame column 16, and is clamped and positioned on the channel steel of the frame column 16 by the outer splint 10 and the inner splint 11 , there is a PTFE sealing ring between the axial end face of the hollow sphere and the outer splint 10 and the inner splint 11, the two axial ends of the hollow sphere 8 are welded with a sphere rotating shaft 18, and are supported by bearing seats 12 at both ends, and are fixed with bolts O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com