Dynamically balanced plow-type unloader

A plow unloader and dynamic balancing technology, applied in the direction of loading/unloading, conveyor objects, transportation and packaging, etc., can solve the problems of fragile conveyor belts, difficult installation and debugging, complex structure, etc., to ensure effective contact, The effect of compact structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

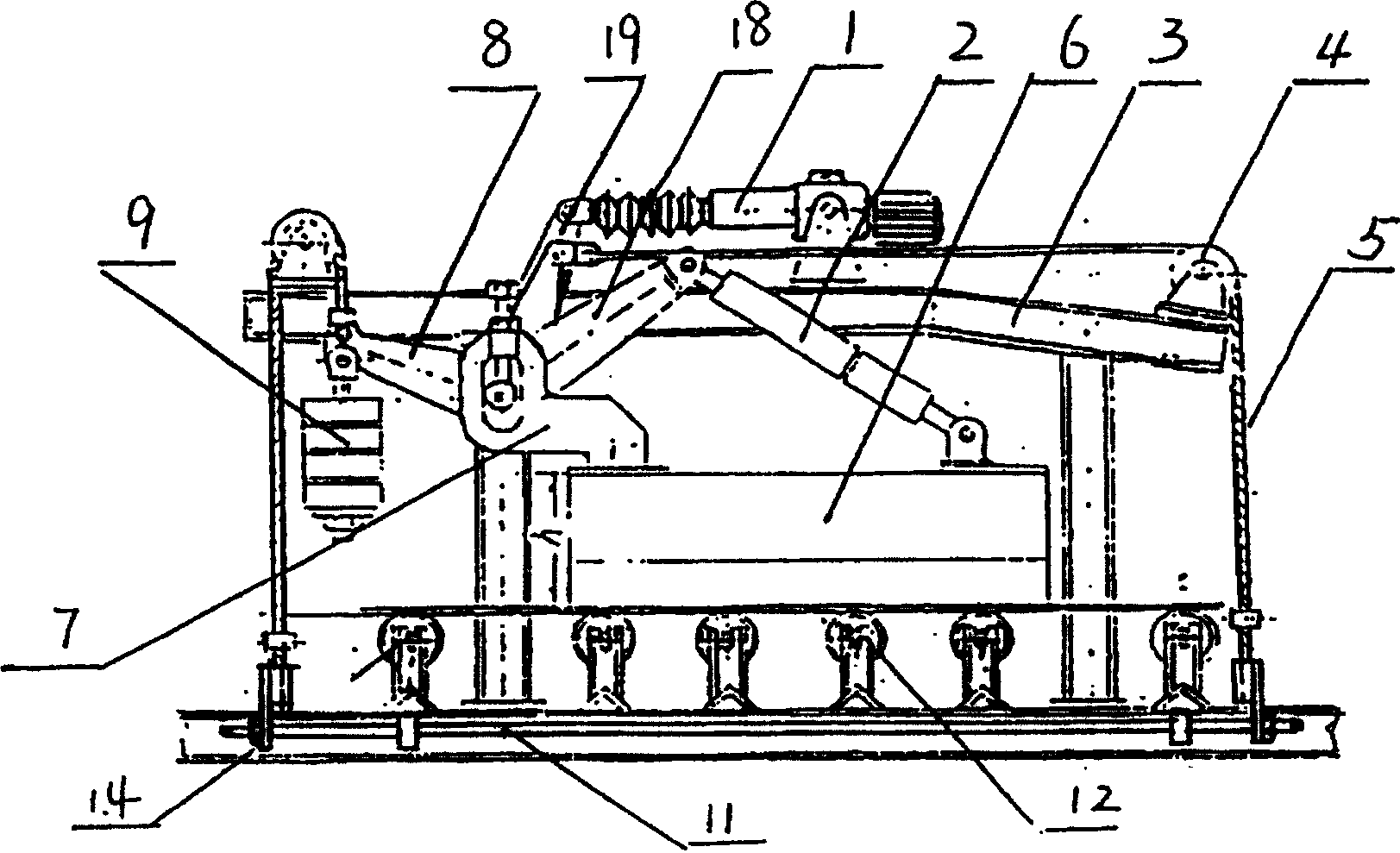

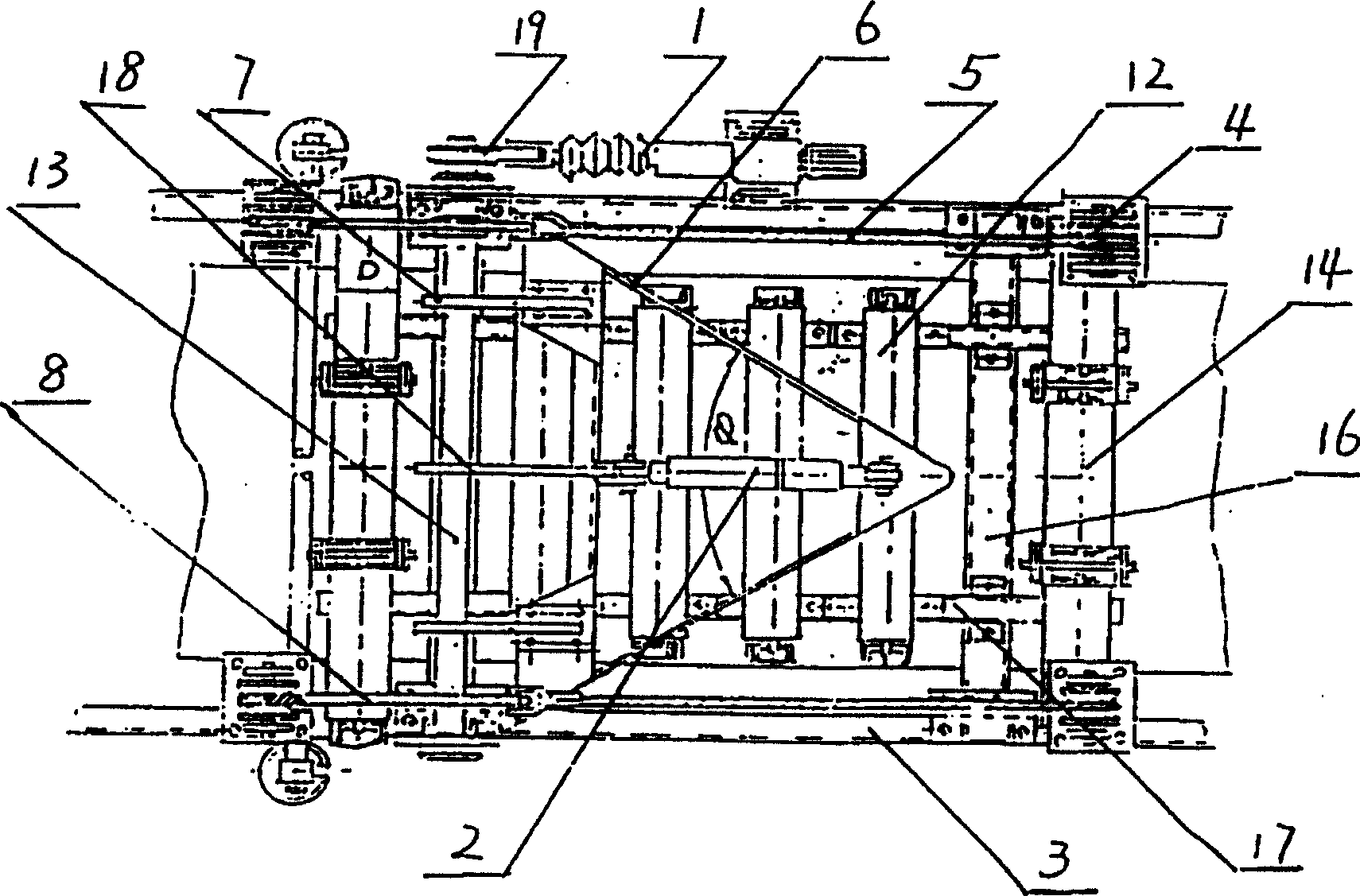

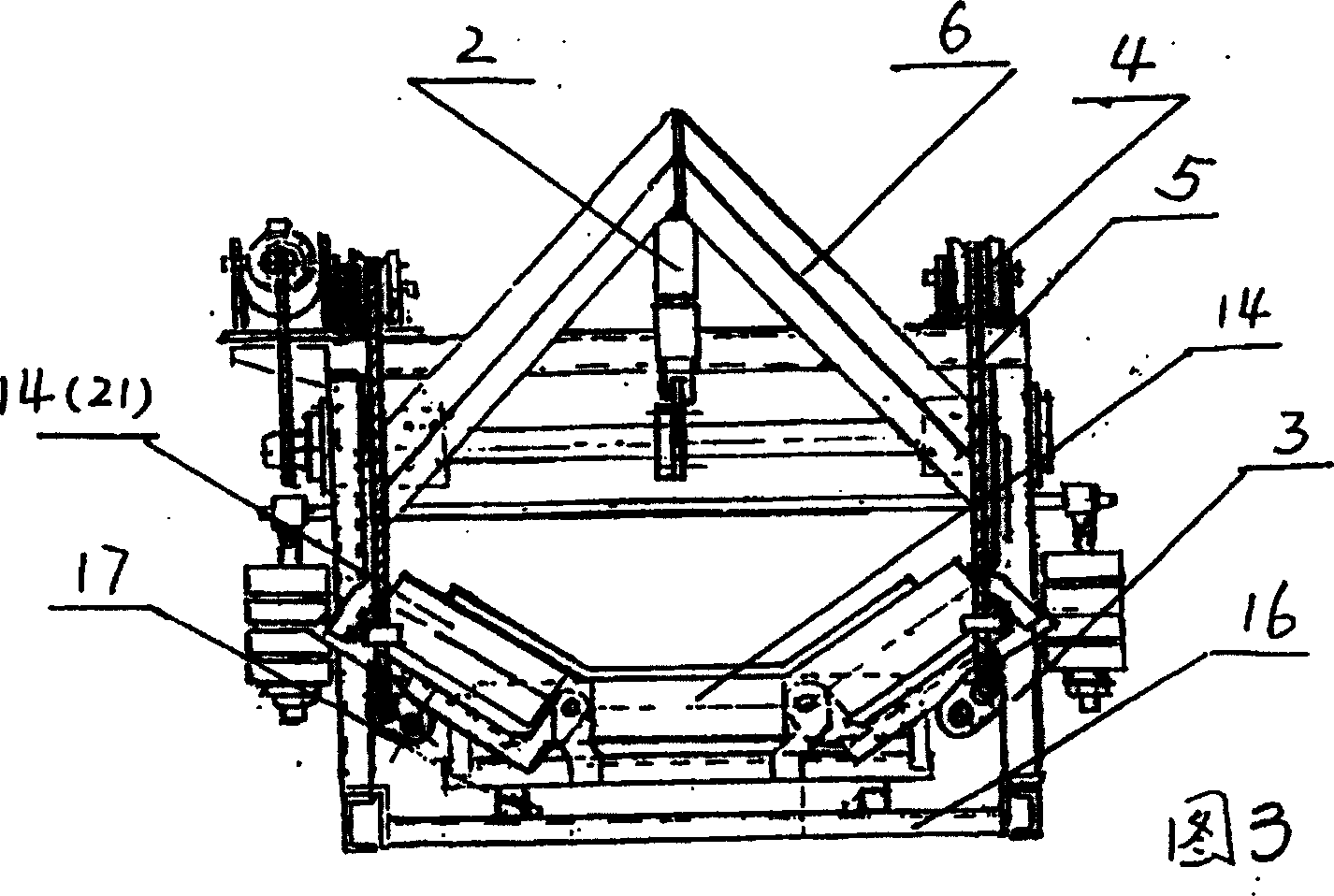

[0011] Below in conjunction with accompanying drawing, the present invention will be further described.

[0012] Depend on Figure 1 Figure II It can be seen that the present invention consists of two quadrilateral frames 3 with the same shape that are integrated through the idler bracket 16. The idler main support 17 is installed on the idler main support 17, and the idler main support 17 is equipped with a The horizontal roller 12 and the deformed roller 14; a set of corresponding vertical longitudinal bars on the frame 3 are equipped with a rotatable knife-edge plate shaft 13, and a pull-rod pole 8 that can act synchronously is installed on the knife-edge plate shaft 13 to adjust the balance. The support 7, the knife-edge plate pull rod 18 and the control arm 19, the control arm 19 is movably connected with the electric push rod 1; the knife-edge plate pull rod 18 is movably connected with the front end of the knife-edge plate 6 through the buffer pull rod 2, and the balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com