Debris shearing blocking box

A technology of cutting feet and shells, which is applied in the field of cutting feet and blocking boxes, can solve the problems of laborious cleaning and reduce operation efficiency, and achieve the effect of saving special cleaning work, improving operation efficiency, and avoiding splashing everywhere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

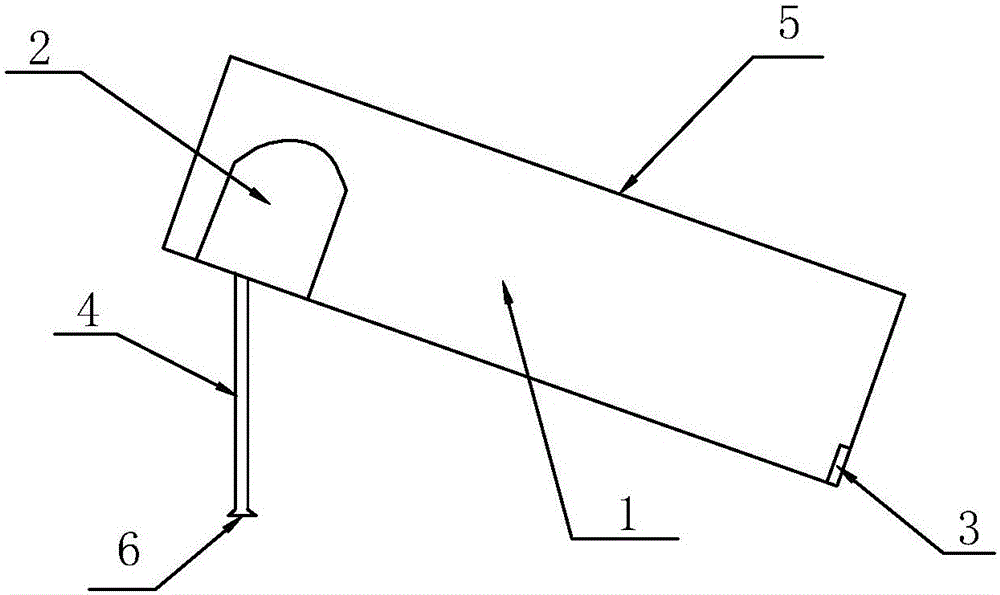

[0014] refer to figure 1 , a kind of scissors box of the present invention, comprises cuboid housing 1, and described housing 1 is provided with the product inlet 2 that is used to put in the product and the outlet 3 that is used to discharge sundry, described housing 1 It is arranged obliquely, and two supporting rods 4 are provided on one side of the housing 1 for supporting this side of the housing 1 , and the upper surface of the housing 1 is provided as a transparent layer 5 . Specifically, the lower part of the support rod 4 is provided with a support seat 6, and the transparent layer 5 is transparent glass. The setting of the transparent layer 5 is mainly for the operator to clearly see the situation inside the box and facilitate operation.

[0015] refer to figure 1 , the product inlet 2 is arranged on one side of the cuboid, and the size of the product inlet 2 can be penetrated into the hands. During operation, the product is manually taken into the blocking box to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com