Non-horizontal-direction insert device and working method thereof

A working method and non-horizontal technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of high installation space and assembly requirements, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

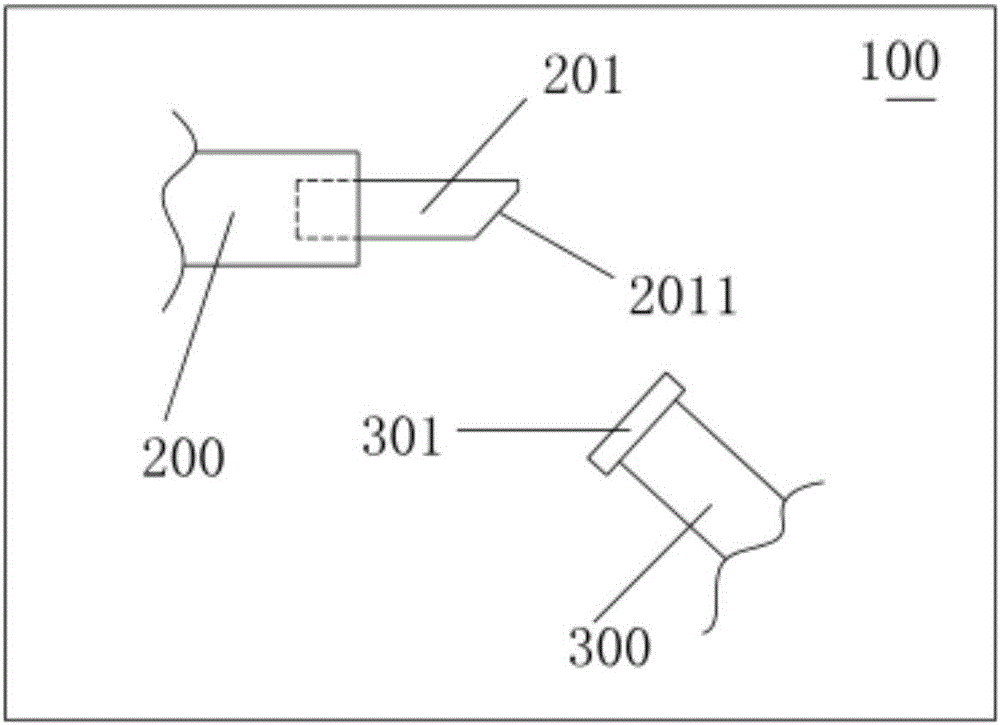

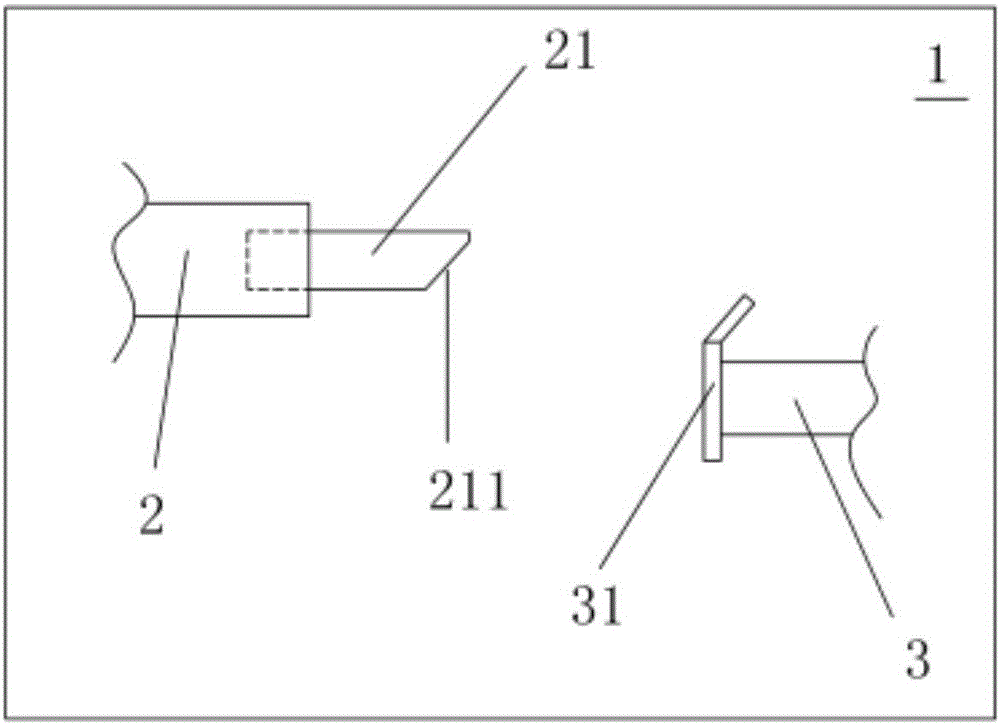

[0027] See Figure 2 to Figure 4 As shown, a non-horizontal direction insert device of a preferred embodiment is shown, wherein,

[0028] The machine tool 1 is an ordinary machine tool, the workpiece gripper 2 is equipped with a workpiece 21, the workpiece 21 has an inclined surface 211, and the insert gripper 3 is equipped with a non-horizontal insert 31, and both the workpiece gripper 2 and the insert gripper 3 are movable Ground installation (that is, adjustable) on the machine tool 1.

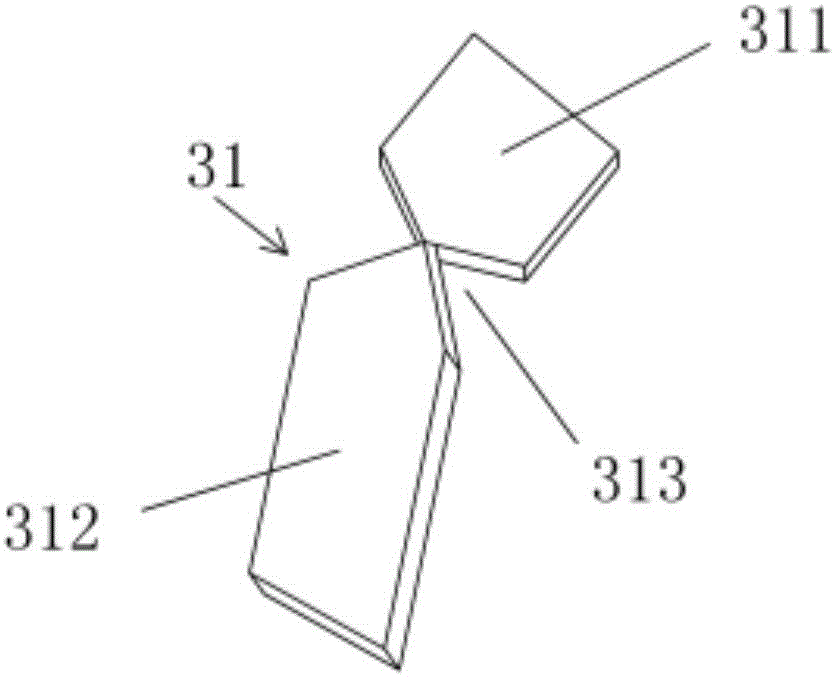

[0029] The insert gripper 3 can be set to move back and forth relative to the workpiece gripper 2. The insert gripper 3 sends the non-horizontal insert 31 to the workpiece gripper 2 and combines with the workpiece 21. The non-horizontal insert 31 is from top to bottom They are an inclined piece 311 and a vertical piece 312 respectively.

[0030] On the basis of the above, the present invention also has the following implementation modes, please continue to refer to Figure 2 to Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com