Compressors with variable compressor inlet

一种压缩机、压缩机壳体的技术,应用在机器/发动机、机械设备、非变容式泵等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

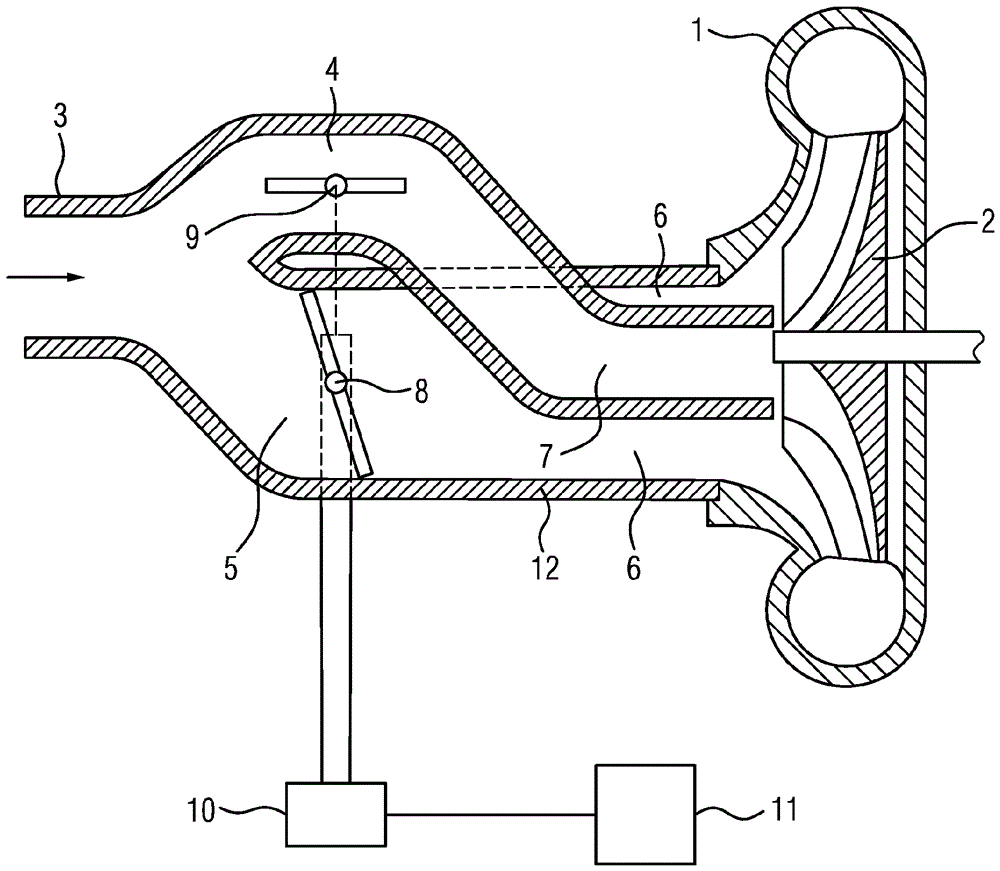

[0020] In the corresponding schematic cross-sectional illustration, a compressor housing 1 with an associated compressor inlet 12 is shown. A compressor wheel 2 with corresponding compressor blades (indicated only schematically) is located in the compressor housing 1. The air flows out from the intake filter (not shown) and flows into the header 3, and from there into the compressor inlet 12. Adjacent to the header 3, the compressor inlet 12 has two separate tubes 4, 5 arranged adjacent to each other into which the header 3 merges. The upper pipe 4 shown in the figure extends into the lower pipe 5 and thus forms two concentric pipes (ie, the inner pipe 7 and the outer pipe 6) and is adjacent to the compressor housing 1 in the area of the compressor inlet 12. In this case, the inner pipe 7 is directed toward the radially inner area, and the outer pipe 6 is directed toward the radially outer area of the compressor blades. In terms of cross section, the inner tube 7 has a ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com