A construction method of concrete drawing form for the well circle of the water intake pump house

A construction method and concrete technology, which is applied in pumping stations, water supply devices, buildings, etc., can solve problems such as unsynchronized construction and high safety risks, and achieve the effects of increasing construction efficiency, solving installation space, and reducing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

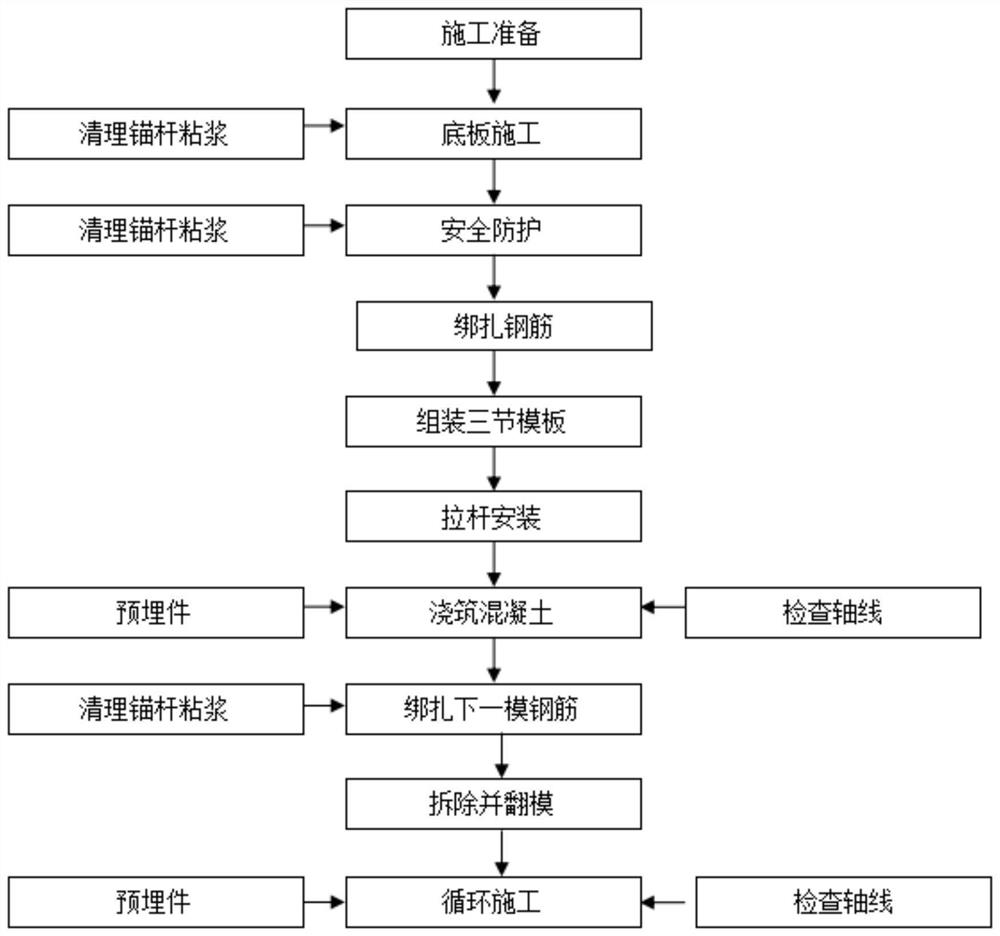

Method used

Image

Examples

Embodiment Construction

[0054] The embodiment of the present invention is illustrated by taking the No. 124 water plant relocation and water supply guarantee project in the downtown area of Yibin City as the ultra-deep and large-span circular water intake pump well ring project of the Pu'an Water Plant. This embodiment realizes the mechanical and electrical facilities for water intake at the bottom of the well The installation was carried out simultaneously with the construction of the well ring, as well as the protection of the equipment and facilities at the bottom of the pump room. During the construction process, the goal of the construction period was accelerated, and the safety risk of the high formwork support was also reduced, which was unanimously received by the owner, design and supervision units. praise.

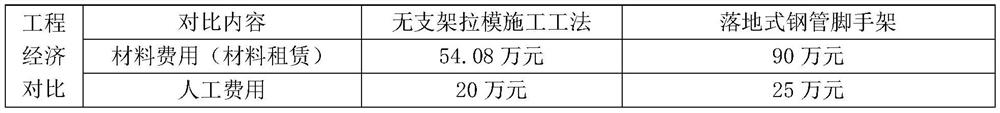

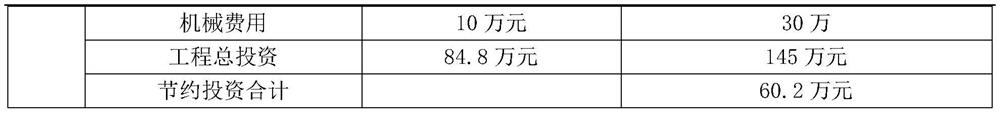

[0055] The materials used in this embodiment are mainly materials such as formwork and section steel, as shown in Table 2.

[0056] Table 2 Main material and equipment list

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com