Vertical wood peeling device based on micro-controller

A microcontroller and wood technology, applied in the field of agricultural and forestry machinery, can solve problems such as complex processing procedures and limit work efficiency, and achieve the effects of reducing costs, improving automation, and liberating productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

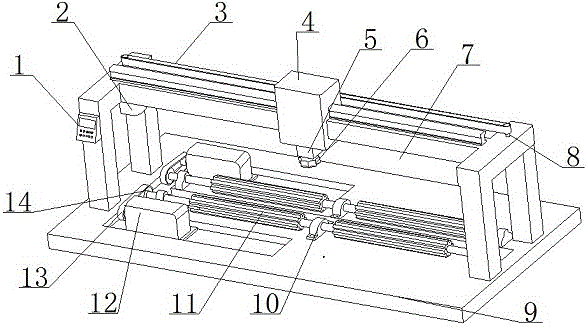

[0009] see figure 1 , the present invention comprises a kind of vertical timber peeling device based on microcontroller, is by microcontroller 1, base 9, first motor 12, synchronous pulley 13, synchronous belt 14, gear pinion shaft 11, fixed bearing 10 , beam 7, mobile platform 4, travel motor 2, steel flat belt 3, support roller 8, second motor 5 and milling cutter 6, it is characterized in that: the first motor 12 is installed on the base 9, the first motor 12 The gear pinion shaft 11 is driven by the synchronous pulley 13 and the synchronous belt 14, the gear pinion shaft 11 is installed on the base 9 through the fixed bearing 10, the beam 7 and the base 9 are connected by welding, and the traveling motor 2 is fixed on the beam 7 directly drives the support roller 8 to rotate, the steel flat belt 3 is pre-tightened by the support roller 8, and the movement of the travel motor 2 drives the steel flat belt 3 to move, thereby driving the mobile platform 4 to move horizontally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com