Novel building construction mortar stirring device

A technology for building construction and stirring device, which is applied to cement stirring devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of inconvenient feeding operation, mortar precipitation, insufficient stirring and uniformity, etc., and achieves convenient feeding and cleaning. The effect of even stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

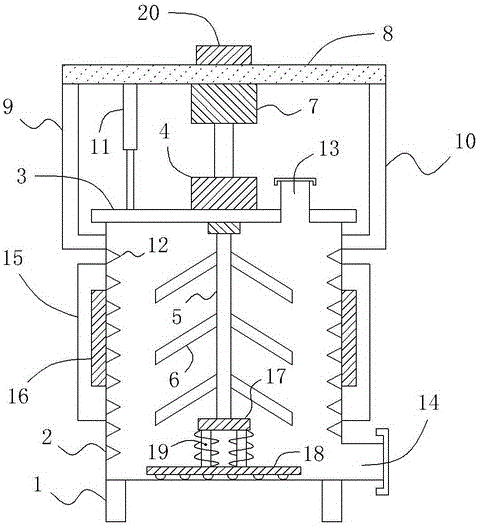

[0013] Such as figure 1 As shown, a new type of mortar mixing device for building construction includes a bracket 1 and a cylinder 2 arranged on the bracket 1. A cylinder cover 3 is also provided on the top of the cylinder 2, and a motor 4 is arranged on the cylinder cover 3. The motor 4 The output shaft of 4 is arranged vertically downwards and stretches to the inside of cylinder 2, and the bottom end of the output shaft of motor 4 is also connected with the stirring shaft 5 that extends vertically downwards, and on the stirring shaft 5, there are evenly distributed A plurality of stirring rods 6; also be provided with hydraulic cylinder 7 directly above motor 4, the piston rod of hydraulic cylinder 7 is arranged vertically downwards, and the bottom end of the piston rod of hydraulic cylinder 7 is fixedly connected with the top of motor 4, in The top of the hydraulic cylinder 7 is also fixedly connected with a horizontally arranged crossbar 8, and the left and right ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com