A method for forming an integrally formed airfoil structure

An integral forming, airfoil technology, applied in other home appliances, home appliances, household components, etc., can solve the problems of long manufacturing cycle, high weight, increased cost, etc., to reduce structural weight, reduce complexity, and reduce overall stress. and good aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for forming an integrally formed airfoil structure, for example, includes the following steps;

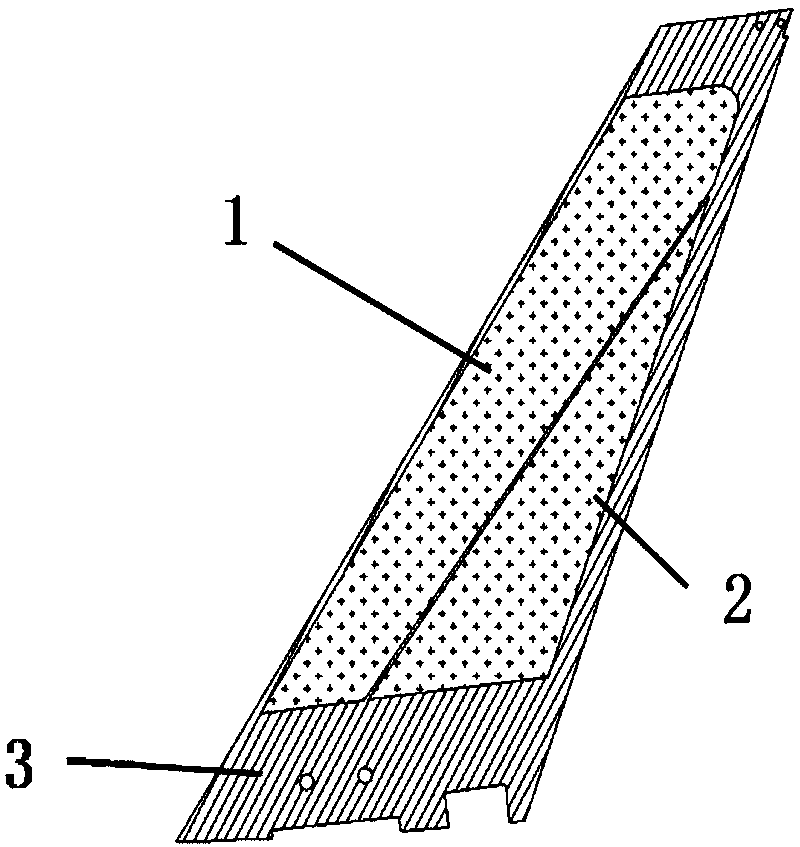

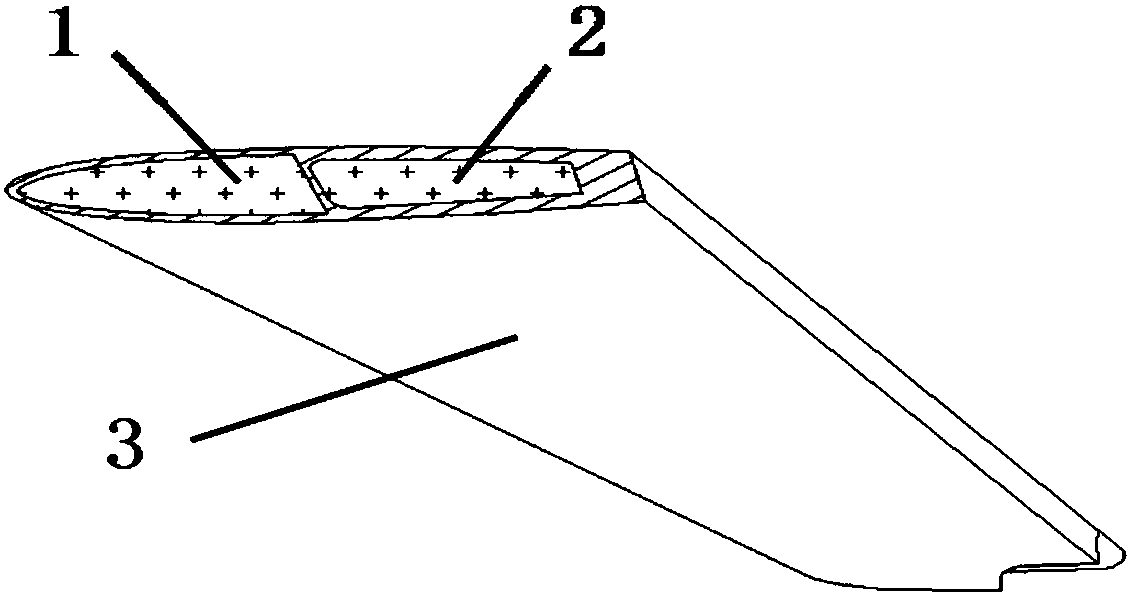

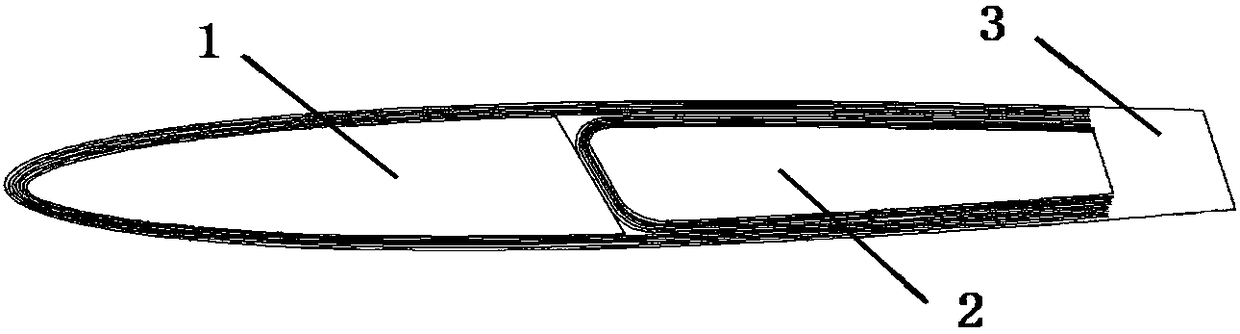

[0025] 1. Design the airfoil interlayer. The airfoil interlayer includes two parts: airfoil interlayer 1 and airfoil interlayer 2. The shapes of airfoil interlayer 1 and airfoil interlayer 2 are the shapes of the airfoil with an inward deviation of 1.8mm and 3.3mm respectively. shape, and make the airfoil structure meet the specified strength and rigidity requirements;

[0026] 2. Wrap 5 layers of carbon fiber prepreg PESEKK / SW400 fabric on the outer surface of the airfoil interlayer 2. The thickness of each layer is 0.3mm, and the direction is not required. Then place the airfoil interlayer 2 and the airfoil interlayer 1 according to the shape of the airfoil. , and wrap 6 layers of carbon fiber prepreg cloth as above, and the layup is allowed to be along the direction of -45°, 0°, +45°, -45°, 0°, -45° on the surface;

[0027] 3. Make a mold that has the same shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com