Cotton tencel spandex fabric with low dyeing and finishing long shrinkage rate

A shrinkage and fabric technology, applied in the field of cotton tencel spandex fabric, can solve the problems of single function and lack of three-dimensional effect, and achieve the effect of low weight consumption in dyeing and finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

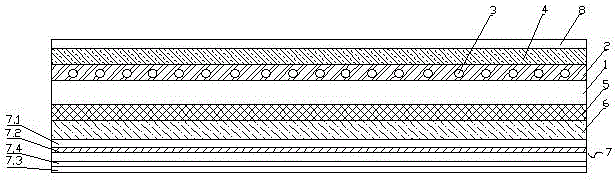

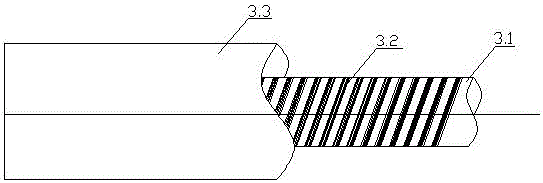

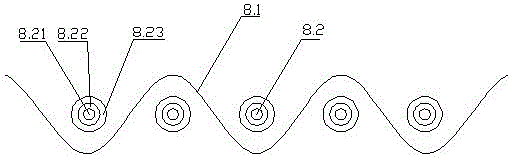

[0024] see Figure 1~3 , a kind of dyeing and finishing low shrinkage cotton tencel spandex fabric related to the present invention, it comprises fabric main body 1, and fabric main body is woven by cotton tencel warp yarn and spandex weft yarn, and the upper surface of fabric main body 1 is provided with anti-radiation layer 2 , the anti-radiation layer 2 is embedded with a plurality of criss-crossing anti-radiation strips 3, the upper surface of the anti-radiation layer 2 is provided with an antistatic layer 4, and the upper surface of the antistatic layer 4 is provided with a high color fastness layer 8, The lower surface of the fabric body 1 is provided with an antibacterial layer 5, the antibacterial layer 5 is woven from silver-plated fibers, the lower surface of the antibacterial layer 5 is provided with a fireproof layer 6, the fireproof layer is woven from polyacrylonitrile fibers, and is fireproof. The lower surface of layer 6 is provided with a waterproof layer 7 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com