Plump, elastic and weave-pattern-imitating leather fabric

A plump and elastic technology, applied in the field of textile fabrics and fabrics, can solve the problems of labor and time-consuming, low price, high cost of natural leather, etc., and achieve the effect of low dyeing and finishing weight consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

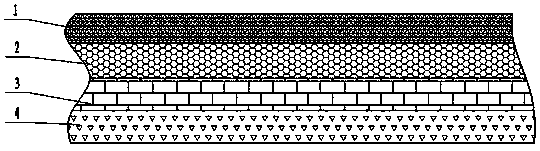

[0014] see figure 1 , the present invention relates to a kind of product plump and elastic imitation weaving texture leather fabric, comprising surface layer, the inner side of said surface layer is provided with indentation retaining layer, undergerm layer and inner layer in turn; said surface layer is made of plastic resin The indentation-retaining layer is made of SEE ecological cotton, and the surface layer and the indentation-retaining layer are bonded to fix the pressing pattern; the subgerm layer is made of polyvinyl chloride artificial leather; the inner lining The layers are woven with bamboo charcoal fibers; each layer is bonded and fixed by hot melt adhesive.

[0015] The back of the inner layer is provided with a lining fabric layer, the lining fabric layer includes the first warp yarn, the second warp yarn, the third warp yarn and the weft yarn. Plain weave, the third warp yarn and the weft yarn form a "V"-shaped structure to form plush, and the second warp yarn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com