Pneumatic tire

A technology of pneumatic tires and beads, applied in tire parts, treads, transportation and packaging, etc., can solve problems such as rim slippage, and achieve the effects of suppressing bending, excellent fitability, and easy fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

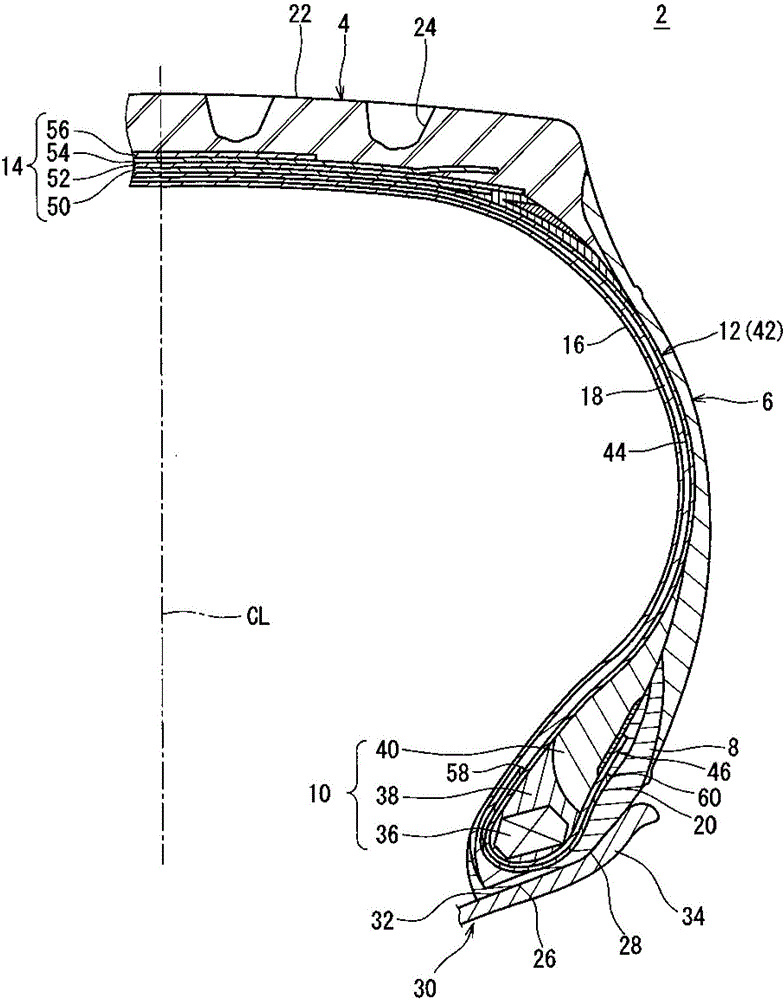

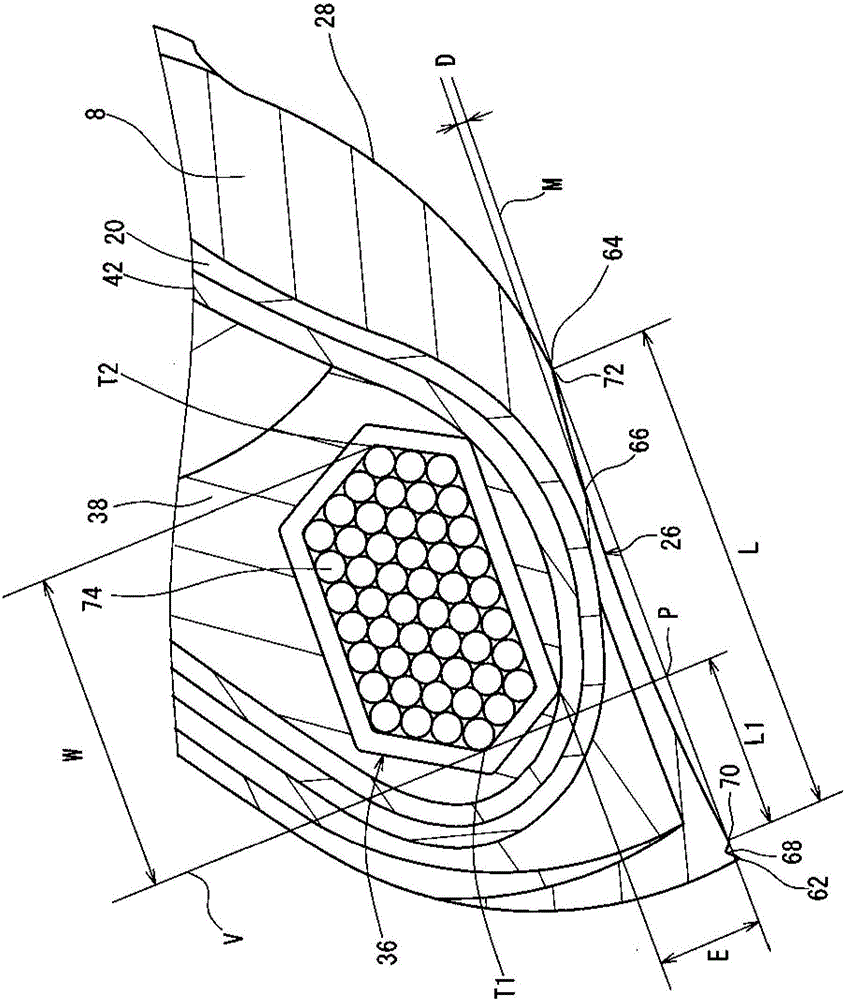

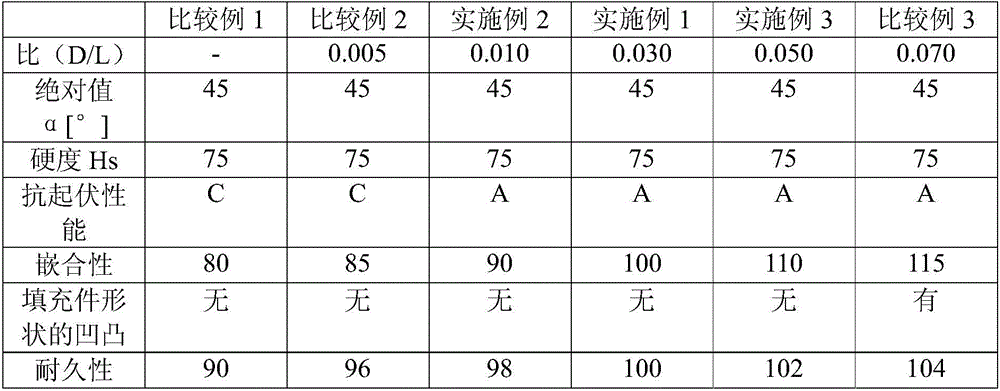

[0066] got to have figure 1 The tire of Example 1 having the structure shown in -2. Set the size of the tire to 11R22.5. Each part of the tire is shown in Table 1. In this tire, the width L of the dimple was 24.3 mm, the width W of the bead core was 16.0 mm, and the distance L1 was 8.5 mm. The cross-sectional shape of the depression is a substantially circular arc. Furthermore, the distance E between the reference line M and the bottom surface of the bead core was set to 7.2 mm. The absolute value θ of the angle formed by the cords of the carcass ply and the equatorial plane was 90°.

Embodiment 2-3、 comparative example 2-3

[0070] Tires of Example 2-3 and Comparative Example 2-3 were obtained in the same manner as in Example 1, except that the depth D of the dent was changed so that the ratio (D / L) was the value shown in Table 1.

Embodiment 4-7

[0072] Tires of Examples 4-7 were obtained in the same manner as in Example 1 except that the absolute value α was set to the value shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com