Canard aerodynamic configuration of subsonic-velocity high-maneuver drone aircraft

An aerodynamic layout and large maneuvering technology, applied in canard aircraft, fuselage, aircraft parts, etc., can solve the problems that the source and number of target aircraft are not fixed, and cannot meet the needs of military training, so as to increase speed, avoid collision damage, The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

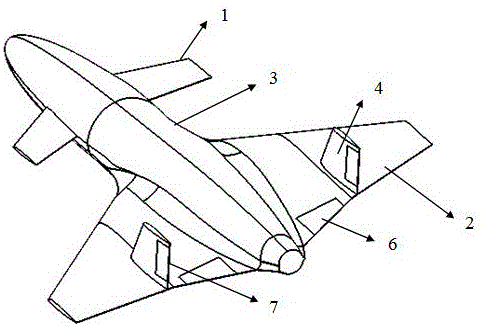

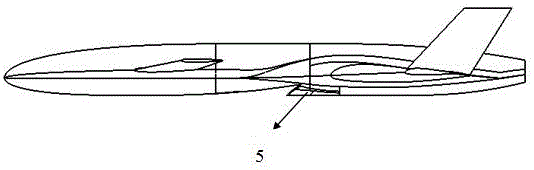

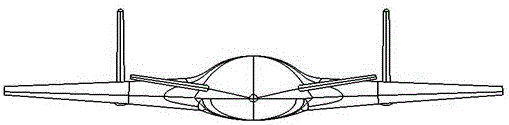

[0018] This embodiment provides a canard aerodynamic layout of a subsonic large maneuvering target drone, such as Figure 1 to Figure 6 As shown, including wing 2, fuselage 3, aileron 6, canard 1, air intake 5, vertical tail 4 and rudder 7, the volume, length, cross-sectional area and other shape parameters of the fuselage are based on the layout requirements of airborne equipment It is finally determined that a pair of canards are arranged symmetrically on both sides of the front of the fuselage. The canards adopt a symmetrical airfoil with a maximum thickness of 12%, the leading edge sweep angle is 32°, and the canard area is 10% of the wing area; A pair of wings are arranged on both sides of the rear. There are ailerons on the outside of the wings. The ailerons can be used as flaps to increase the lift according to the flight status. The sweep angle is 40° and the wing area is 1.6㎡. Double vertical tails are installed on the wings. The vertical tail adopts a symmetrical air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com