Sealing mechanism for large-size sealed case

A technology for sealing a box and a sealing mechanism, applied in the field of sealing mechanisms, can solve problems such as stress instability and air leakage of the sealing ring, and achieve the effects of reliable sealing, easy manufacturing and simple flange structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

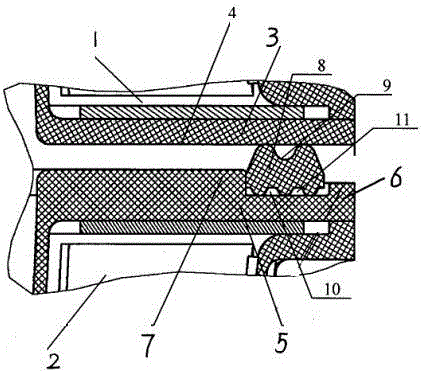

[0011] The present invention is described in detail below in conjunction with accompanying drawing:

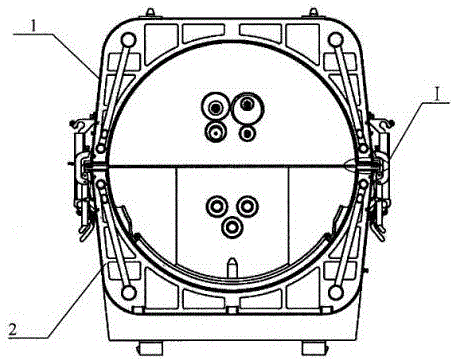

[0012] A sealing mechanism for a large-sized sealed box, including a box cover 1 and a box body 2, a box cover flange 3 is arranged on the box cover 1, a box body flange 5 is arranged on the box body 2, and in the box body method The flange 5 is provided with a sealing ring embedding groove, and a sealing ring 8 is embedded in the sealing ring embedding groove, an upper annular groove 9 is provided on the upper end surface of the sealing ring 8, and etc. The height of the lower inner annular groove 10 and the lower outer annular groove 11, the height of the inner step 7 on the box flange 5 inside the sealing ring embedded in the groove is greater than the outer side of the box flange 5 on the outer side of the sealing ring embedded in the groove The height of the step 6, the height of the outer step 6 on the box flange 5 on the outside of the sealing ring embedded in the groov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap