Ceramic scraper plate cleaner

A cleaner and scraper technology, which is applied in the field of ceramic scraper cleaners for belt conveyors, can solve problems such as structural defects, insufficient hardness, and insufficient strength, and achieve the effects of improving service life, not easy to scratch, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

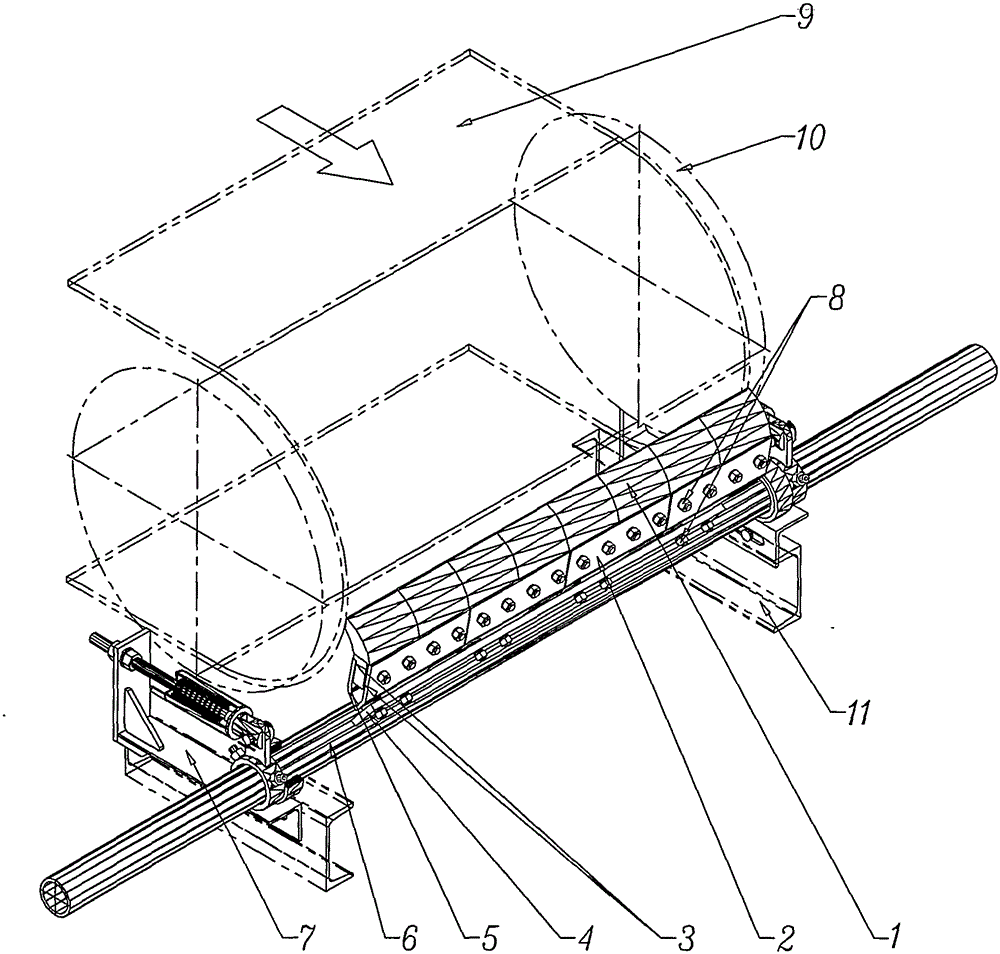

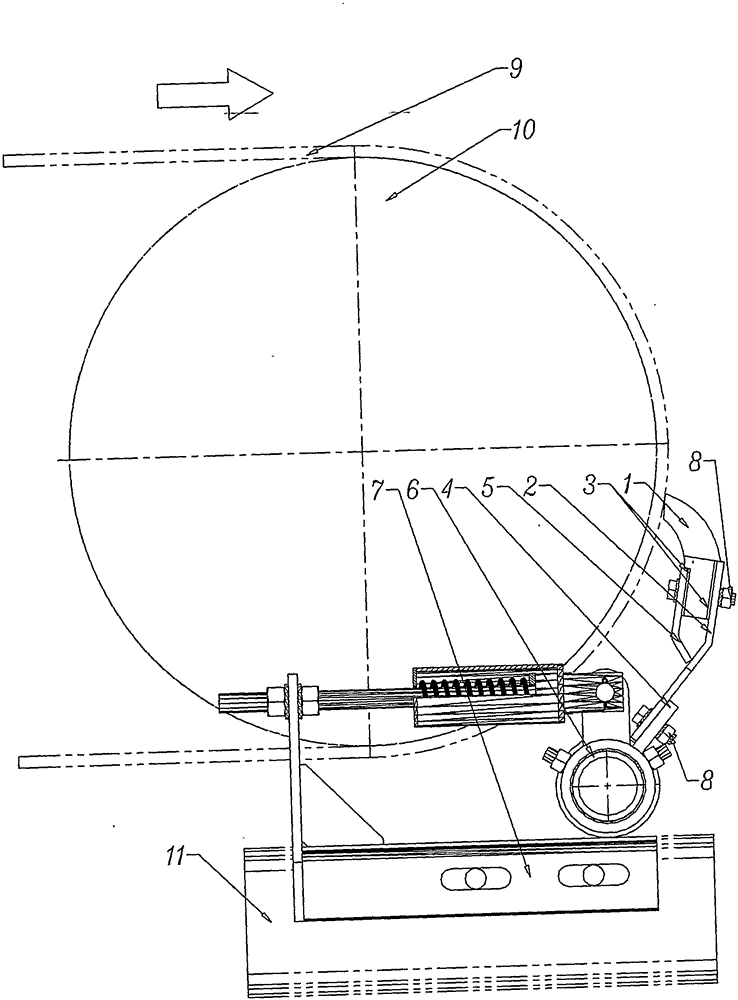

[0016] figure 1 It is drawn according to the belt width of 800 mm, but the present invention is not limited to this specification. This drawing is an isometric drawing, combined with image 3 , you can clearly see the ceramic scraper (1), scraper connecting plate (2), rubber pad (3), fixed plate (4), pressure plate (5), swing tube (6), fixed seat and spring adjustment mechanism (7), bolts and nuts (8), conveyor belt (9), drive roller (10), the installation position and mutual relationship of these parts of frame edge beam (11).

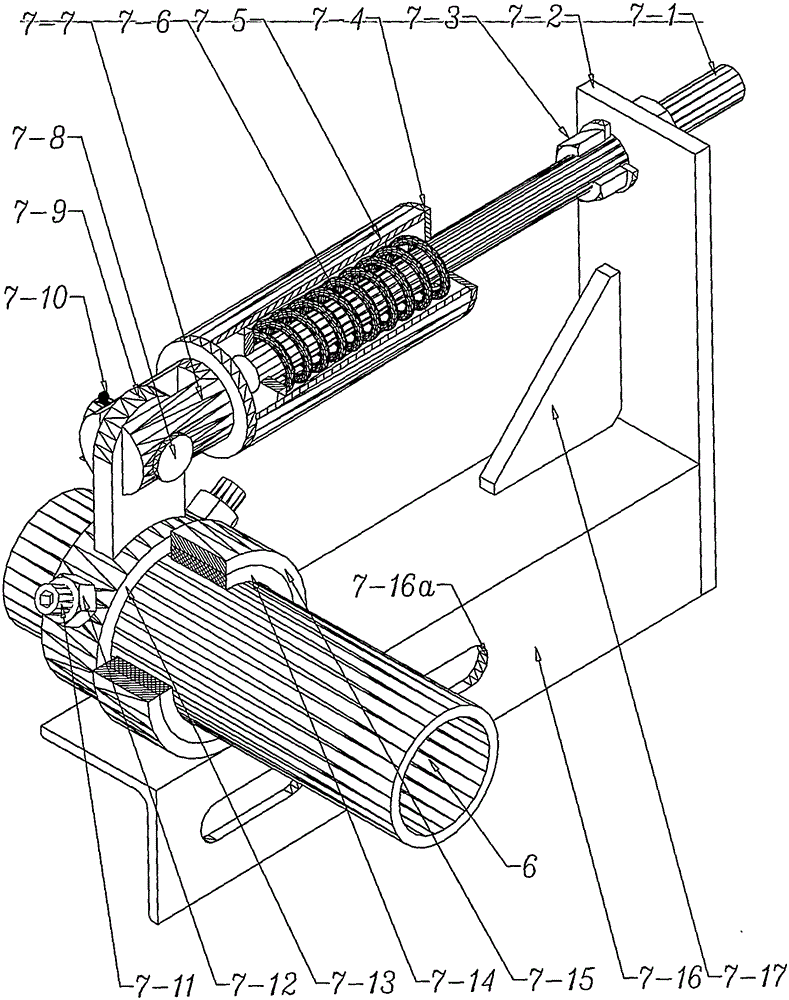

[0017] figure 2 yes figure 1 The enlarged view of the middle fixing seat and the spring adjustment mechanism (7). In the figure, the swing tube (6) has been cut short, and some parts have been cut at 90° to see the covered parts clearly. Tighten the screw rod (7- 1) It is not drawn in the thread diagram, and it is represented by a round bar. The function of the fixed seat and the spring adjustment mechanism (7) is to fix the swing pipe (6), conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com