Lens press fit and vibrating falling device

A technology of pressing device and lens, which is applied in the direction of measuring device, transportation and packaging, and testing of machine/structural components, etc., can solve the problems of leakage operation, high labor intensity and long time consumption of employees, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

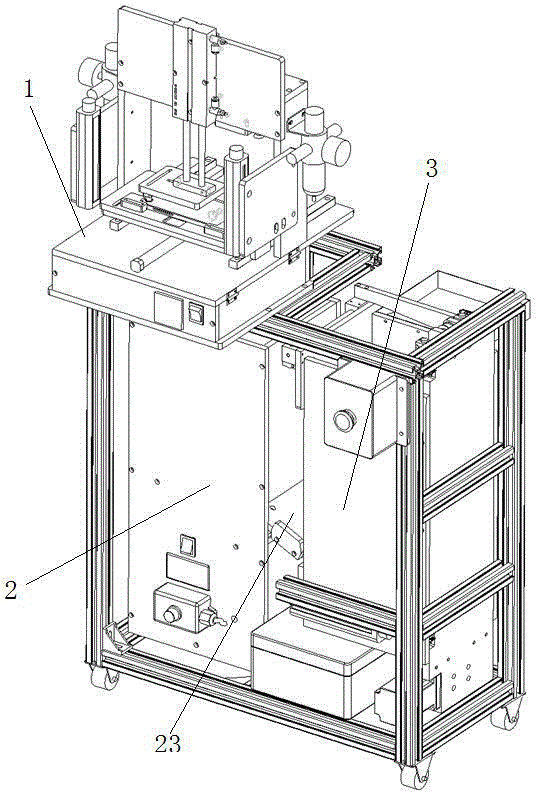

[0016] Such as figure 1 The lens pressing and dropping device shown includes a pressing device 1 for installing a mobile phone camera lens, a vibration drop box 2 for performing a drop test on a mobile phone, and a lifting device 3. The pressing device 1 is located in the vibration drop box 2, the lifting device 3 is arranged on the side of the vibration drop box 2, and the side of the vibration drop box 2 is provided with a chute 23 to communicate with the inside of the lifting device 3. After completing the pressing process on the pressing device 1, the mobile phone falls into the vibration drop box 2 for a drop test. After the test is completed, it can slide into the lifting device 3 from the chute 23, and is lifted upward by the lifting device 3, which is convenient for the operator to pick up.

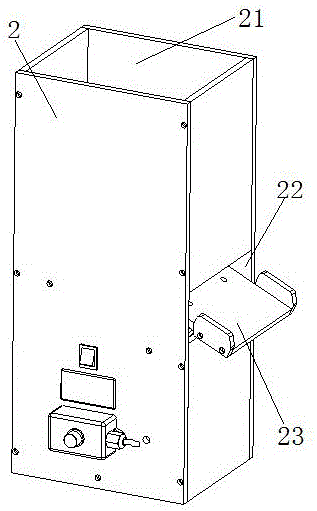

[0017] Such as figure 2 A material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com