Multifunctional transport packaging frame for hollow glass

A multi-functional, packaging rack technology, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as the inability to improve the utilization efficiency of packaging racks, the use of transport packaging racks, and the damage of insulating glass, so as to reduce the phenomenon of bumps, Convenient transportation and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

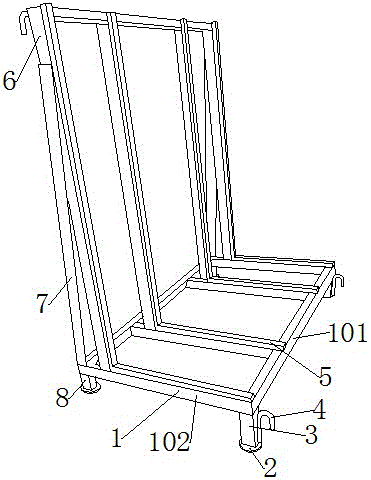

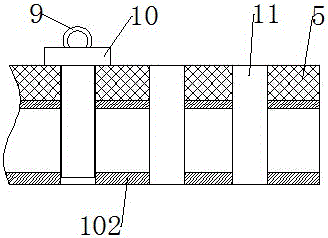

[0023] As shown in the figure, a multi-functional transport and packaging frame for insulating glass includes a bottom frame 1 and a vertical frame 6. The bottom frame 1 is in a rectangular structure and includes a long side 101 and a short side 102. The number of long sides 101 is two, and Parallel to each other, the number of short sides 102 is four, and parallel to each other, and the long side 101 is divided into three equal parts, the upper surface of the short side 102 is provided with a buffer layer 5, and the buffer layer 5 is fixedly connected to the short side 102. 102 and the cushioning layer 5 are provided with a limit hole 11, a limit pin 10 is arranged on the limit hole 11, a pull ring 9 integrally formed with the limit pin 10 is arranged on the top of the limit pin 10, and a pull ring 9 integrally formed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com