A method for lifting a nacelle

A nacelle and lifting beam technology, applied in the field of hoisting the nacelle, can solve problems such as difficult control of the inclination angle of the nacelle, aggravating the inclination of the nacelle, damage to mechanical equipment, etc., to achieve the effect of guaranteeing the lifting effect, realizing equal distribution, and reducing the cost of unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for lifting a nacelle, providing a lifting beam, one side surface of the lifting beam is provided with a first hook and a first ring for connecting with a hook of a hoisting machine, the number of the first hook and the first ring Similarly, the first hook and the first ring are arranged symmetrically with respect to the vertical axis of the lifting beam, and a second hook or a second ring for fixing to the engine room is provided on the other side of the lifting beam relative to the hook;

[0037] Arrange at least three lifting points on the base of the generator in the engine room,

[0038] Install at least two lifting machines on the side of the engine room carrier vehicle, each lifting machine is connected to the lifting beam through the first hook or the first ring, and the second hook or the second ring is provided with a connecting rope for connecting with the lifting point Fixed, lift the lifting beam from the ground and turn it to the top of the engine...

Embodiment 2

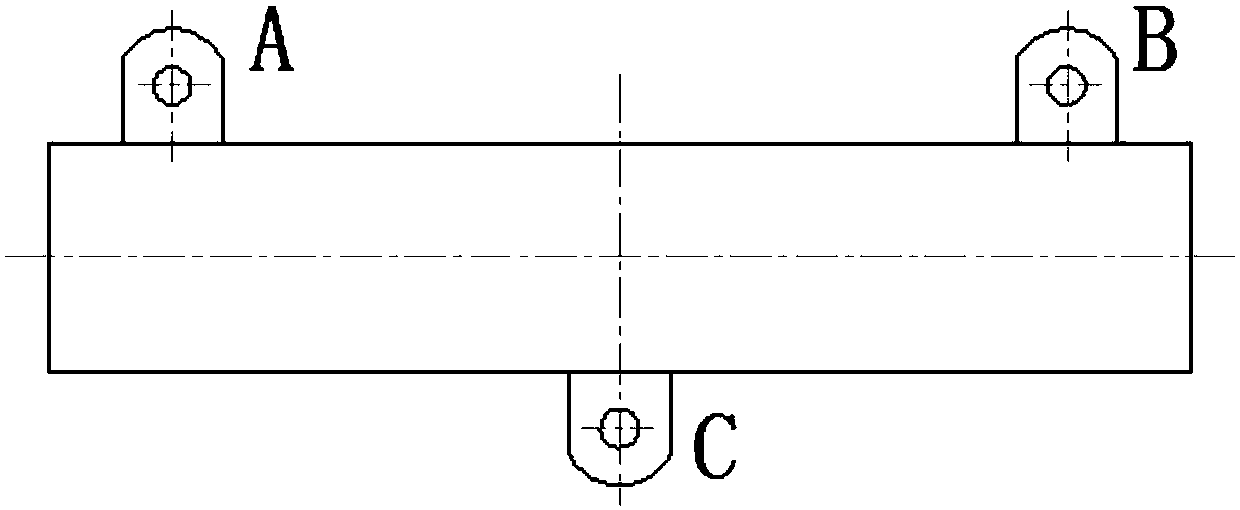

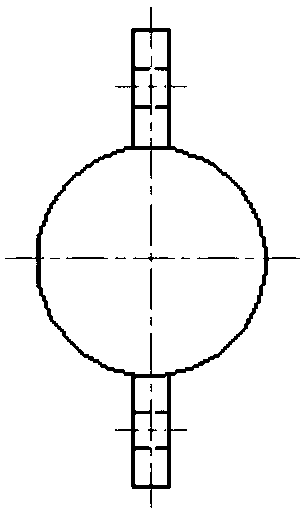

[0041] Such as figure 1 and figure 2 As shown, a method for hoisting the nacelle, providing a hoisting beam, one side surface of the hoisting beam is provided with two first left hoisting rings A and first right hoisting hoops B for connecting with hoisting mechanical hooks, and the two The other is set at a set distance, and each of them can be replaced by the first hook. The first hook or the first ring is arranged symmetrically with respect to the vertical axis of the lifting beam. On the other side of the lifting beam relative to the hook A second hook or second ring C for fixing to the engine room is provided; when in use, the first hook or the first ring is arranged on the upper surface of the lifting beam, and the second hook or the second ring C is arranged on the upper surface of the lifting beam. The lower surface of the hanging beam, the first suspension ring and the second suspension ring are connected with the lifting beam by welding.

[0042]Wherein, in order ...

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 is: the hook of the hoisting machine is fixed to the first hook or the first ring by a wire rope or a chain cable, the second hook or the second ring is fixed to one end of the chain cable, and the other end of the chain cable is fixed. It is fixed with the lifting point of the generator base, and the chain cables are provided with at least three, preferably four.

[0049] Wherein, the lifting points on the base of the generator are arranged symmetrically.

[0050] In order to further ensure the stability of the suspension of the nacelle, the horizontal distance between the first suspension ring and the end face of the lifting beam is 1 / 12 to 1 / 8 of the length of the lifting beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com