A Design Method of Tensile Sliding Isolation Bearing

A technology of seismic isolation bearing and design method, which is applied in the directions of earthquake resistance, building type, building, etc., can solve the problems of poor vertical tensile resistance structure, poor anti-overturning ability, poor shock absorption effect, and high rigidity of seismic isolation layer. Achieve the effect of improving the shock absorption effect, increasing the vertical bearing capacity and reducing the stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

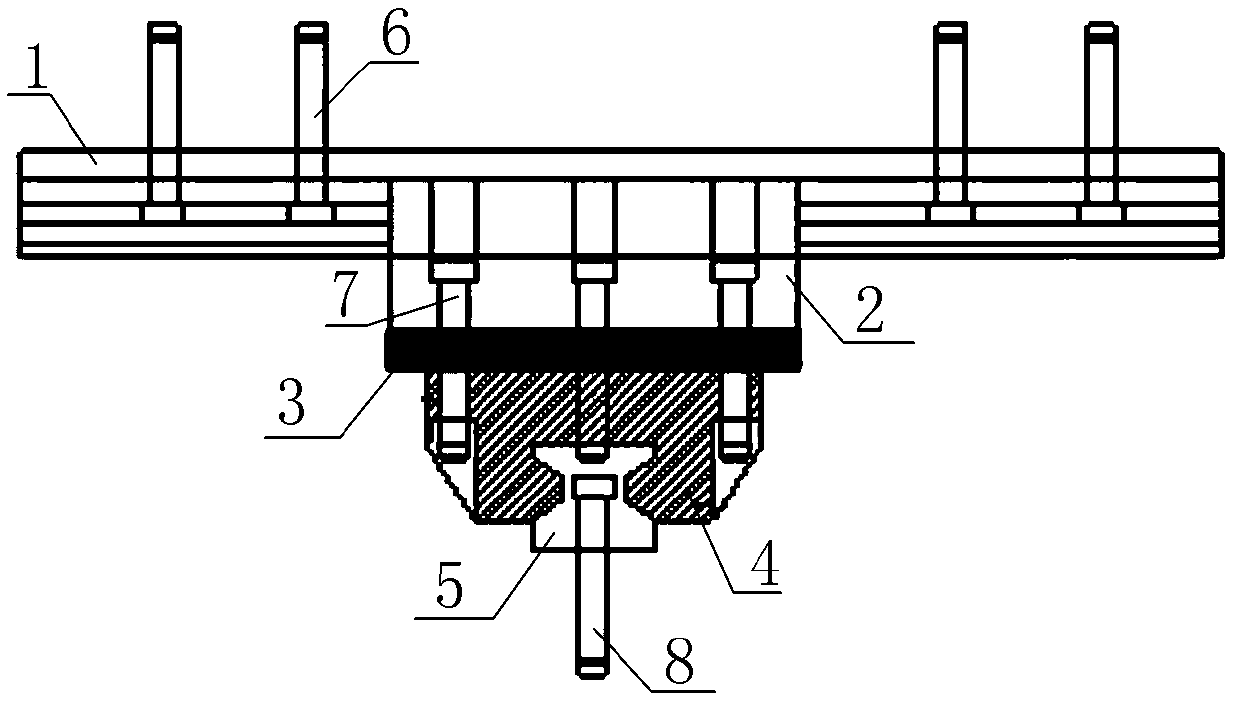

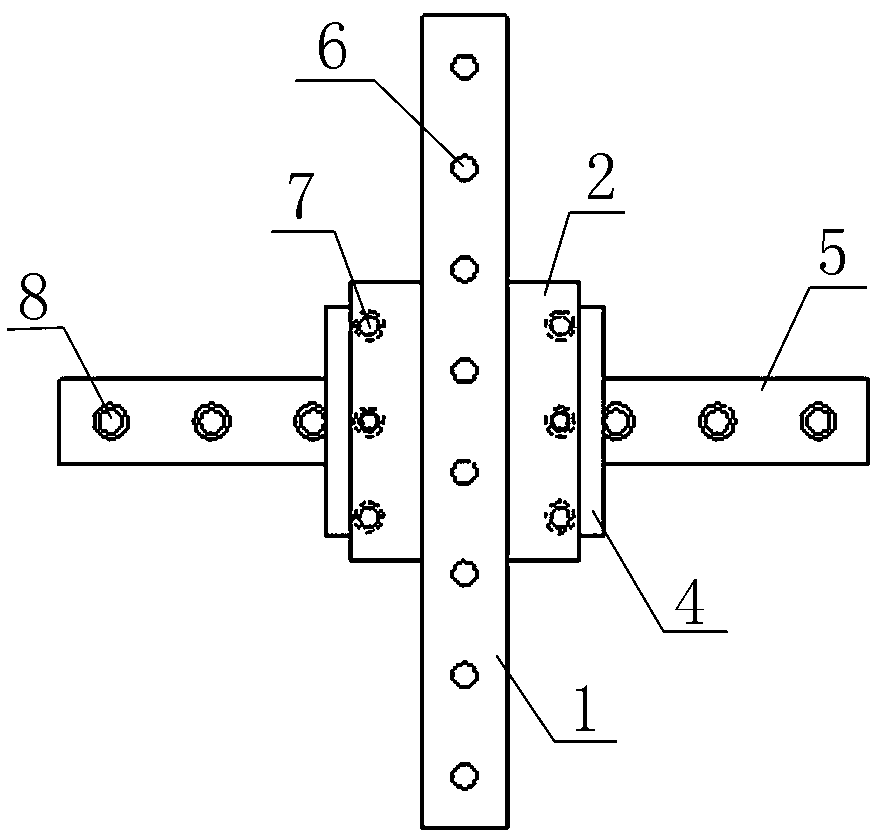

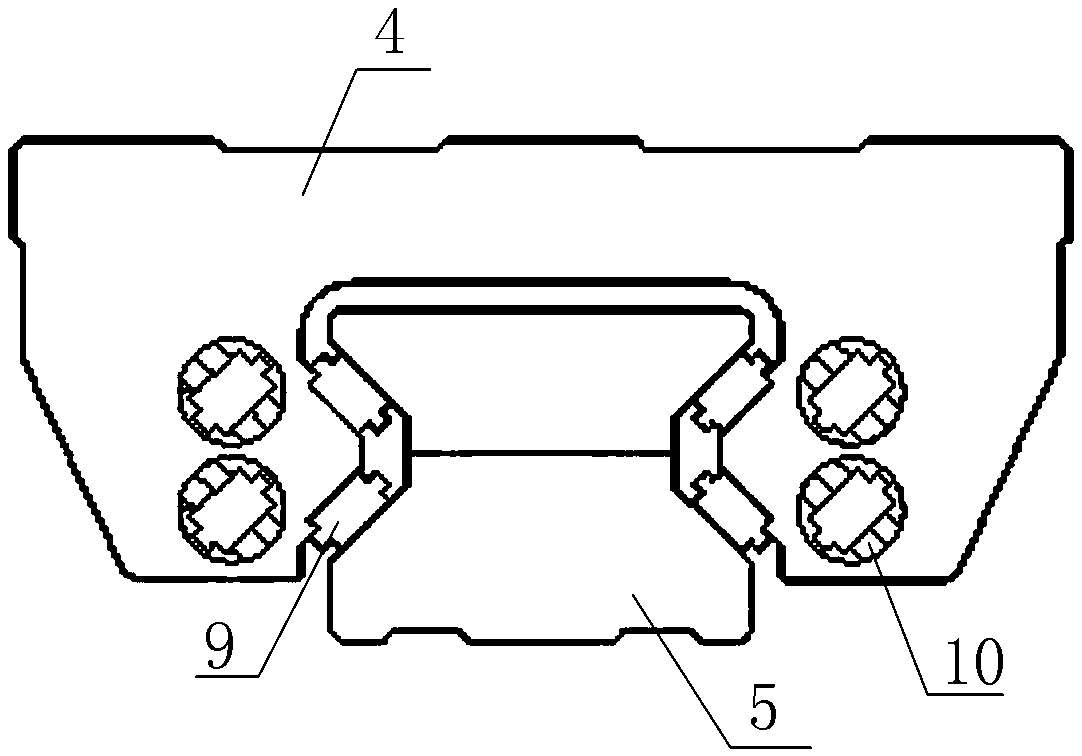

[0038] A tensile-resistant sliding shock-isolation support for buildings is composed of an upper slider 2, a lower slider 4, an upper guide rail 1, a lower guide rail 5, a rubber intermediate layer 3 and a connecting piece 7.

[0039] In this embodiment, the composition and function of each part are as follows.

[0040] The upper and lower guide rails are respectively connected to the upper buttress 11 and the lower buttress 12, and there are corresponding structural reserved screw holes at the connecting positions of the upper buttress 11 and the lower buttress 12.

[0041] The connecting piece 7 connects the upper and lower sliders and the rubber intermediate layer 3 together, so that the support becomes a whole.

[0042] The rubber interlayer 3 can adjust the vertical stiffness of the support, and at the same time provide a certain bending deformation capacity.

[0043] The roller 9 is used as the rolling element between the slider and the guide rail, which effectively imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com