A fast-installation corner code for profile frame doors and windows and its application method

A corner code and profile technology, applied in the direction of windows/doors, building components, buildings, etc., can solve the problems of increasing production, storage and transportation, construction period and cost, high labor intensity, inconvenient installation, etc., to shorten the installation or maintenance. The effect of cycle, saving materials and man-hours, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

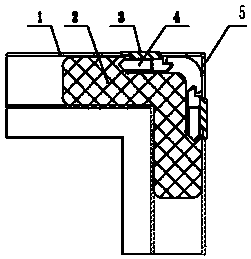

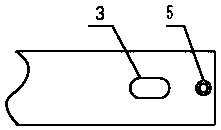

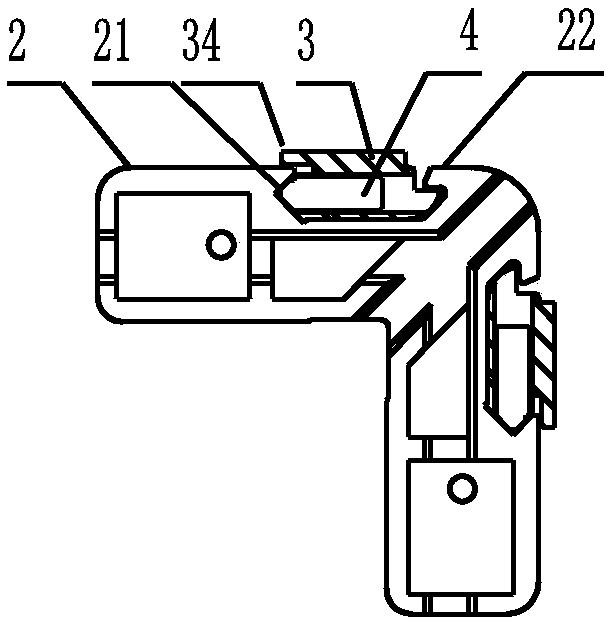

[0027] The present invention is described below in conjunction with accompanying drawing and embodiment: Embodiment: referring to accompanying drawing, a kind of firm quick-loading corner code of profile frame door and window is provided with corner code body and fixing part, and described corner code body 2 is a kind of right angle Shape, on the side of two right-angled sides, be respectively provided with a fixing member installation hole, each fixing member installation hole is provided with a fixing member 3, the shape and size of each fixing member are just in line with the corresponding fixing member installing hole match; a threaded screw hole 4 is provided at the bottom of the fixing piece, and a fastening screw is arranged in the screw hole; the outer wall of each fixing piece mounting hole is the right-angled side wall of the corner code body There is a screw mounting hole 5 for installing the fastening screw, the inner end of the screw mounting hole is opposite to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com