Screw drill

A screw drilling tool and screw technology, which is applied to drilling equipment, earthwork drilling, and driving devices for drilling in boreholes. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

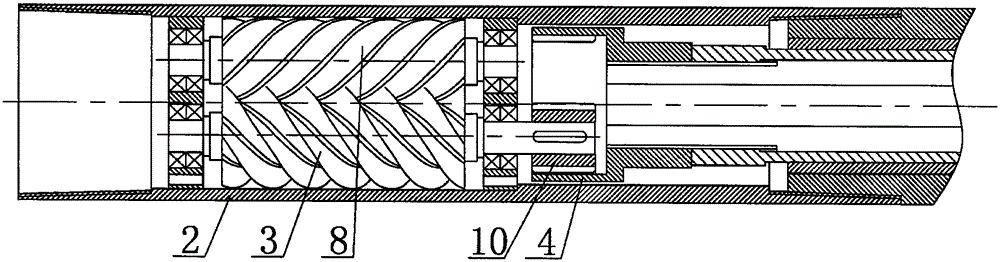

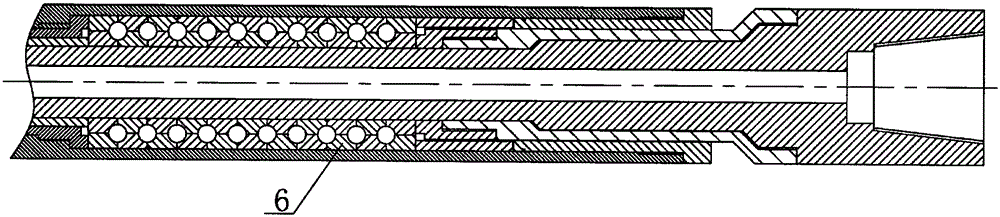

Embodiment 1

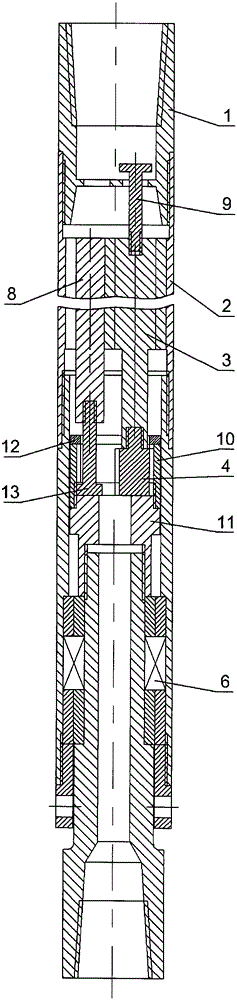

[0019] Such as image 3 As shown, the screw drilling tool is composed of an anti-drop joint 1, an anti-drop rod 9, a motor assembly, a transmission shaft assembly and an intermediate connecting part. In order to improve the service life of the gears, the material of the internal gear 10 and the external gear 4 is designed to be solid carbide, but because the hardness of the cemented carbide is too high, it can only be processed by wire cutting. In order to facilitate the processing of gears by the wire cutting processing equipment, the internal gear 10 and the external gear 4 are designed as spur gears, so that the tooth shape can be completely processed by wire cutting. In order to prevent damage to other parts of the gear except the tooth shape during wire cutting, the gear is designed as follows: the outer contour of the outer gear 4 except the tooth shape is within the cylindrical surface of the dedendum, and the inner contour of the other parts of the inner gear 10 except...

Embodiment 2

[0023] Such as Figure 4 As shown, the screw drilling tool is composed of the anti-drop joint 1, the anti-drop rod 9, the motor assembly, the transmission shaft assembly and the intermediate connecting parts. The axes of the motor assembly and the transmission shaft assembly form a small angle, and the bending point at the internal gear. In order to improve the service life of the gears, the material of the internal gear 15 and the external gear 16 is designed to be solid carbide, but because the hardness of the cemented carbide is too high, it can only be processed by wire cutting. In order to facilitate the processing of gears by wire cutting equipment, the internal gear 15 and the external gear 16 are designed as straight bevel gears, so that the tooth profile can be processed by wire cutting. In order to prevent damage to other parts of the gear except the tooth shape during wire cutting, the gear is designed as follows: the outer contour of the outer gear 16 except the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com