Bolt set with anti-loosening function

A bolt group and anti-loosening nut technology, applied in the direction of bolts, screws, nuts, etc., can solve the problems of loose bolt connections, connection failures, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

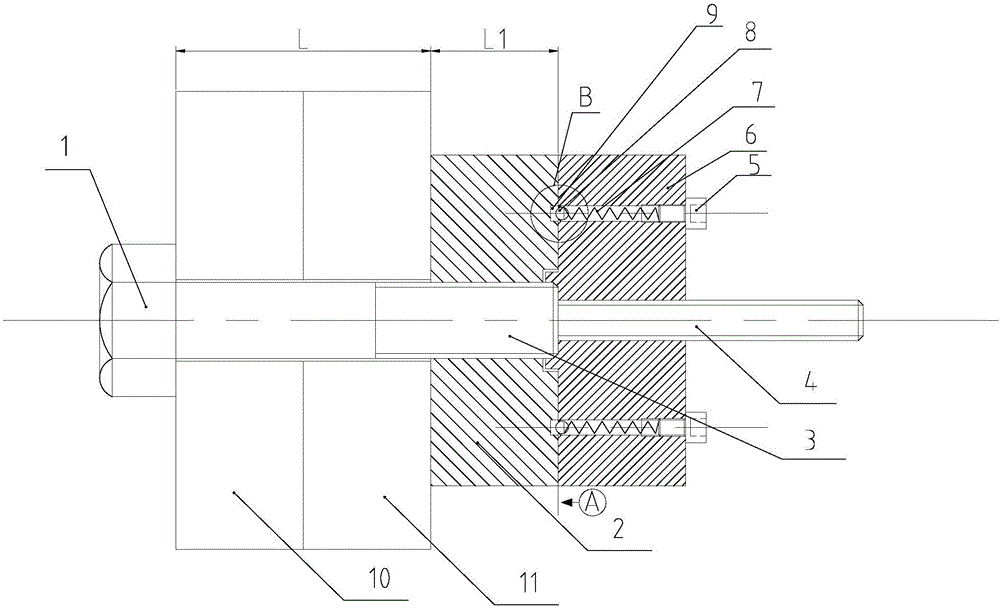

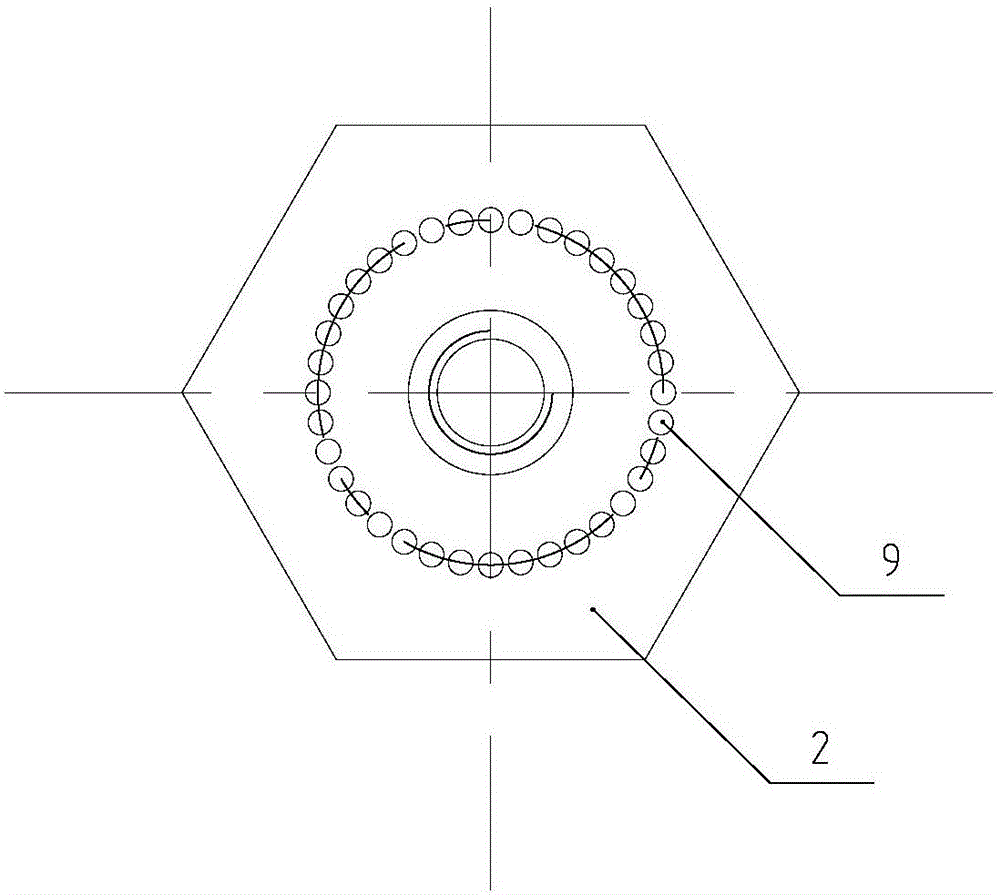

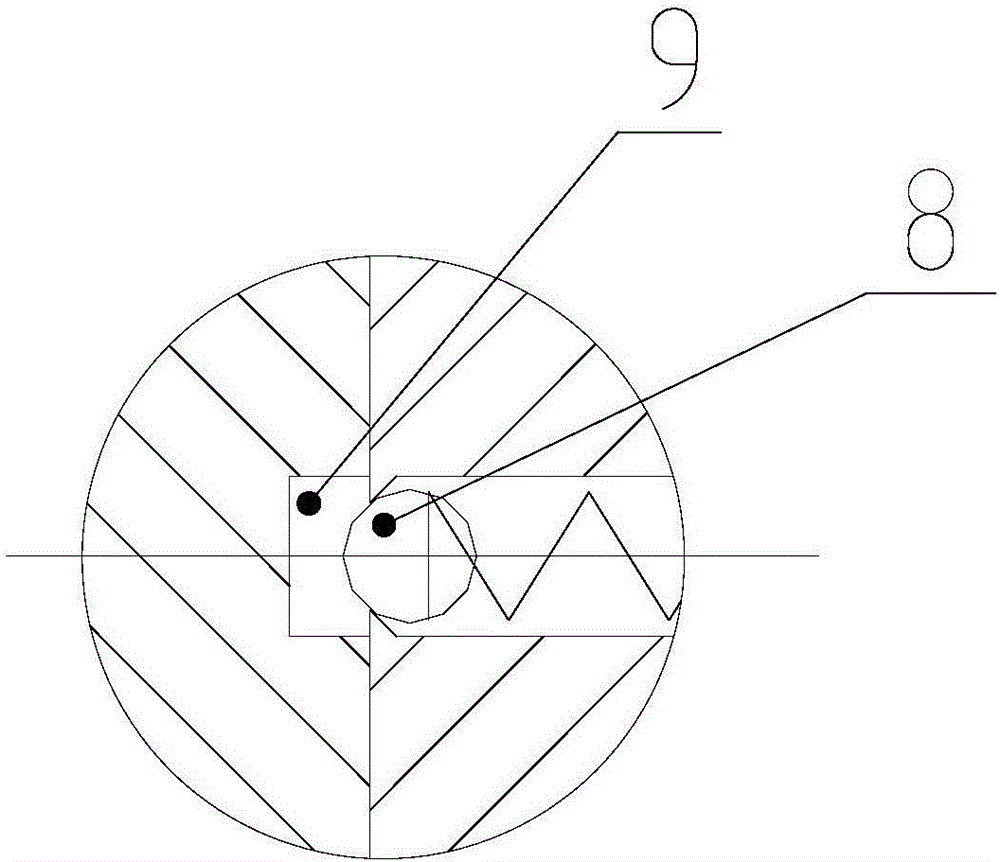

[0022] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0023] See Figure 1-Figure 2 , a bolt group with anti-loosening function, including two-section bolt 1, pre-tightening nut 2, and anti-loosening nut 6, the two-section bolt 1 is provided with two sections of thread sections with different diameters, and the direction of rotation of the two sections of threads On the contrary; the pre-tightening nut 2 is screwed with the large-diameter threaded section 3, and the locknut 6 is screwed with the small-diameter threaded section 4; a groove 9 is provided on the end surface of the pre-tightened nut 2 , a through hole is provided at a position corresponding to the position of the pre-tightening nut groove 9 on the locknut 6, a jacking wire 5 is screwed at one end of the through hole, and a steel ball 8 is provided at the other end of the through hole, A spring 7 is arranged between the steel ball 8 and the top wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com