Energy saving clutch

A clutch and assembly technology, applied in the field of auto parts, can solve the problems of high work intensity of drivers, low degree of automation, wear and tear of parts, etc., and achieve the effects of good fuel saving, labor intensity reduction, and wear reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

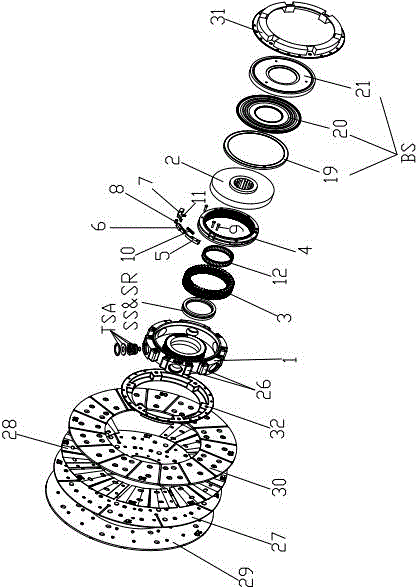

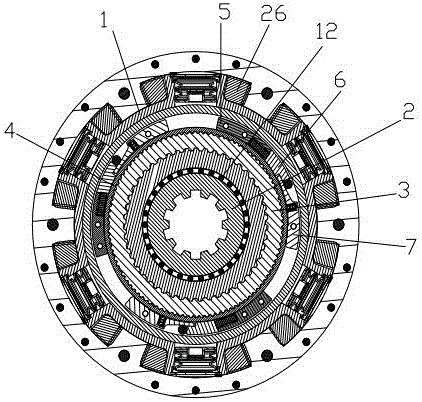

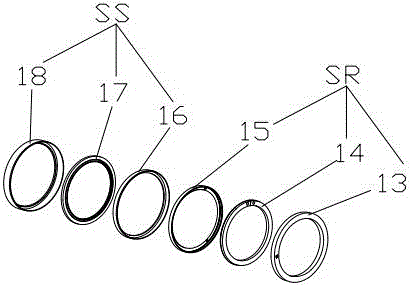

[0031] like Figure 1-7 As shown, the energy-saving clutch of the present invention includes a coaxial driving disc 1, a passive disc 2, a first helical sleeve 3, a second helical sleeve 4 and an active steel plate 27, and the middle part of the space formed by the driving disc 1 and the passive disc 2 is installed There is a first helical sleeve 3, the left helical key set in the inner diameter direction of the first helical sleeve 3 is slidingly matched with the left helical key set on the driving disk 1, and the right helical key arranged radially outside the first helical sleeve 3 is in contact with the second helical sleeve 4. The right screw key arranged radially inside is slidingly fitted; one end surface of the first spiral sleeve 3 is provided with a ratchet 301, and the corresponding end surface of the passive disc 2 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com