Fireproof valve

A fire damper and valve frame technology, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of rough production quality, high material cost, and difficult handling, etc., and achieve good bending resistance, increase utilization rate, and reduce weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

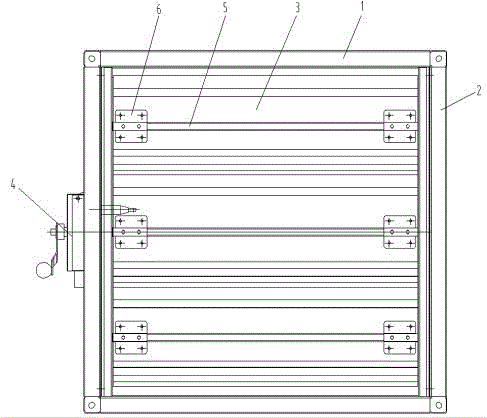

[0014] like figure 1 As shown, the present invention discloses a fire damper, comprising a rectangular valve frame surrounded by two parallel horizontal frame rods 1 and two parallel mullion rods 2 and a valve frame rotatably connected between the two mullion rods 2 Several valve slices 3 connected to the rotating rod 5 through the fixed piece 6, and the actuator 4 fixed on the valve frame control the rotation of the rotating rod 5 through the actuator 4, thereby controlling the opening and closing of the valve slice 3 to To realize the opening and closing of the fire damper, to sum up, it is basically consistent with the structure of the existing common fire damper.

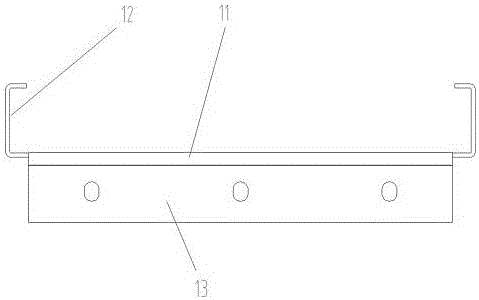

[0015] like figure 2 As shown, the fire damper of the present invention is mainly innovative in that the transverse frame rod 1 includes a long and narrow main rod body 11, and the two long sides of the main rod body 11 have anti-bending reinforcement sheets 12 respectively. The two short sides of the main ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com