Vertical cross flow air conditioner with air capable of going out from top and control method

An air conditioner, a technology for ejecting air, applied in heating and ventilation control systems, control input involving air characteristics, space heating and ventilation control input, etc., can solve the problems of increasing assembly difficulty, casing wear, and high manufacturing costs , to achieve the effect of improving the degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

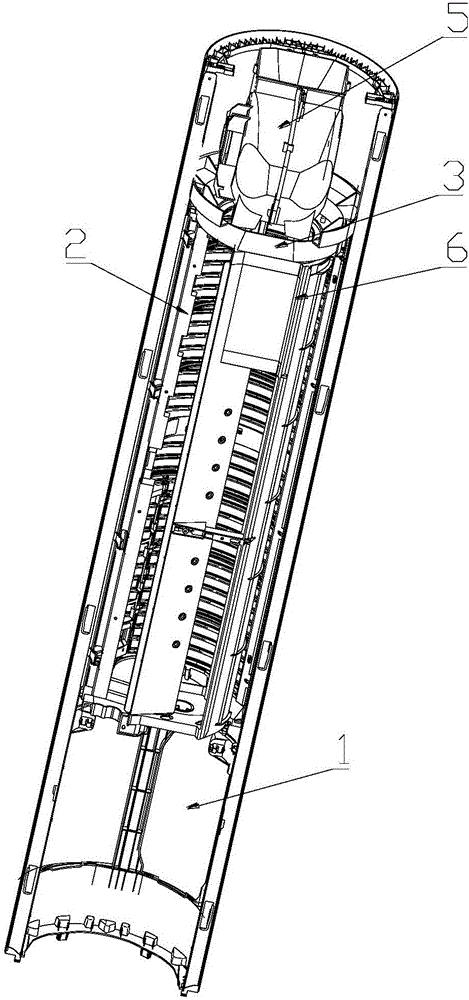

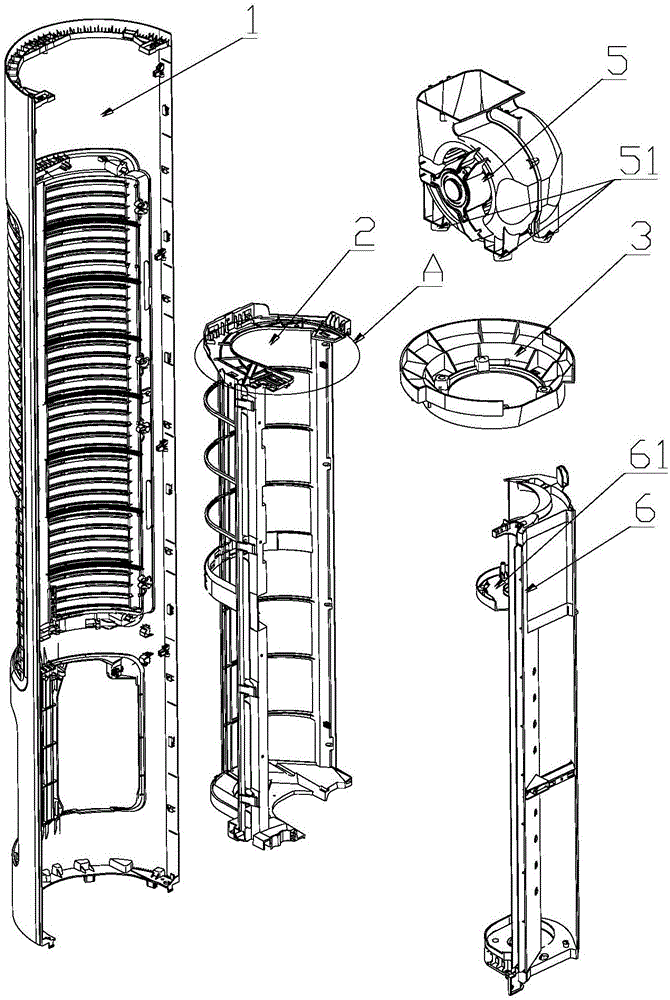

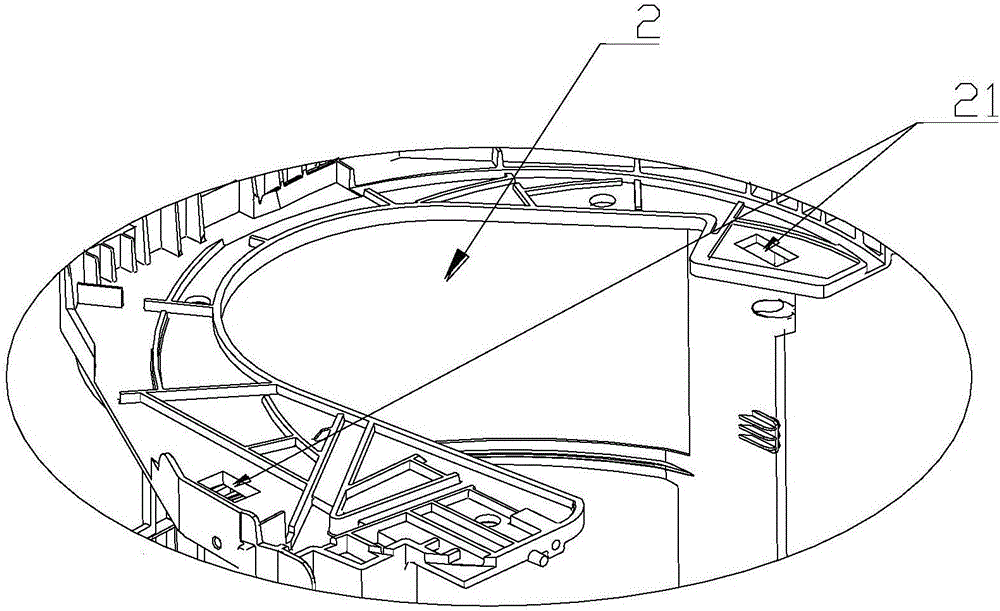

[0048] like figure 1As shown, a vertical cross-flow air conditioner with air outlet from the top includes a casing 1 with a long cylindrical structure arranged vertically, a heat exchanger assembly and a volute assembly 6 installed in the casing 1 , the mounting bracket 3, the top air outlet assembly 5 and the front air outlet assembly; the upper end of the volute assembly 6 is fixedly connected to the upper end of the heat exchanger assembly by screws, and the lower end of the volute assembly 6 is connected to the heat exchanger assembly by screws. The lower end of the heater assembly is fixedly connected, and the volute assembly 6 forms an air cavity with the casing 1, the heat exchanger assembly, and the top air outlet assembly 5, and the middle part of the air cavity is fixed with a The air chamber is divided into an upper chamber and a lower chamber by a partition 61; a part of the heat exchanger assembly is located in the upper chamber, and another part is located in the...

Embodiment 2

[0060] A control method for a vertical cross-flow air conditioner as described in Embodiment 1, comprising the following steps:

[0061] S1, turning on the vertical cross-flow air conditioner, and selecting an automatic operation mode;

[0062] S2. When the temperature detection device detects that the current room temperature is greater than the preset temperature value, control the vertical cross-flow air conditioner to operate in cooling mode, and the front air outlet assembly and the top air outlet assembly are turned on at the same time. The humidity detection device detects the current humidity;

[0063] At this time, if the humidity detection device detects that the current air humidity is lower than the preset humidity range, control the heat exchanger assembly to increase the temperature and reduce the frequency of the compressor, and the front air outlet assembly and the top air outlet assembly continue to operate. Run at the same time; if it is detected that the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com