Tandem coil heat exchanger

A technology of heat exchangers and rows, applied in the direction of indirect heat exchangers, heat exchanger types, fixed tubular conduit components, etc., can solve the problems of large heat exchanger size and insufficient heat transfer rate, and achieve axial The effect of short size, fast heat replacement, and short heat radiation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

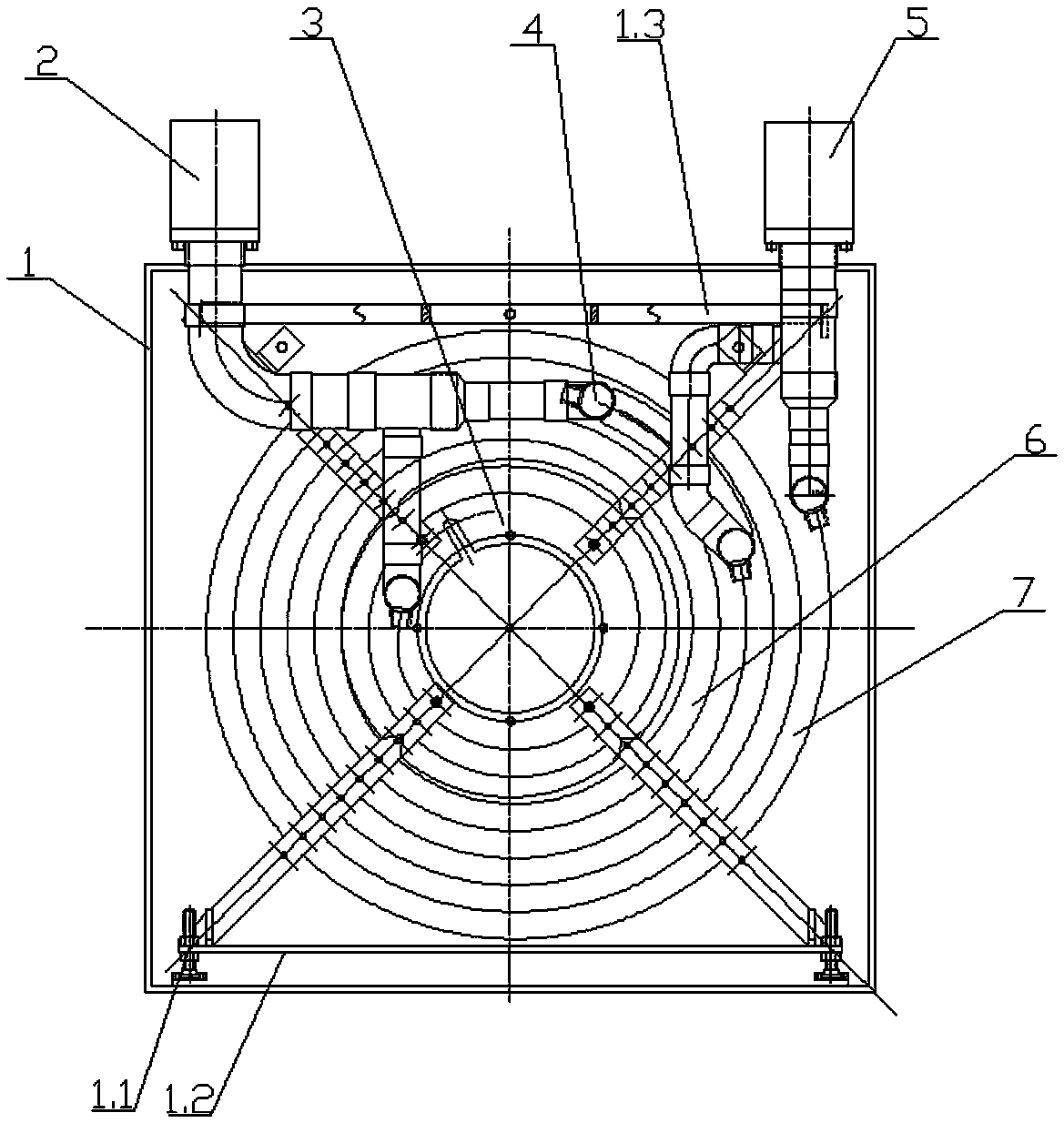

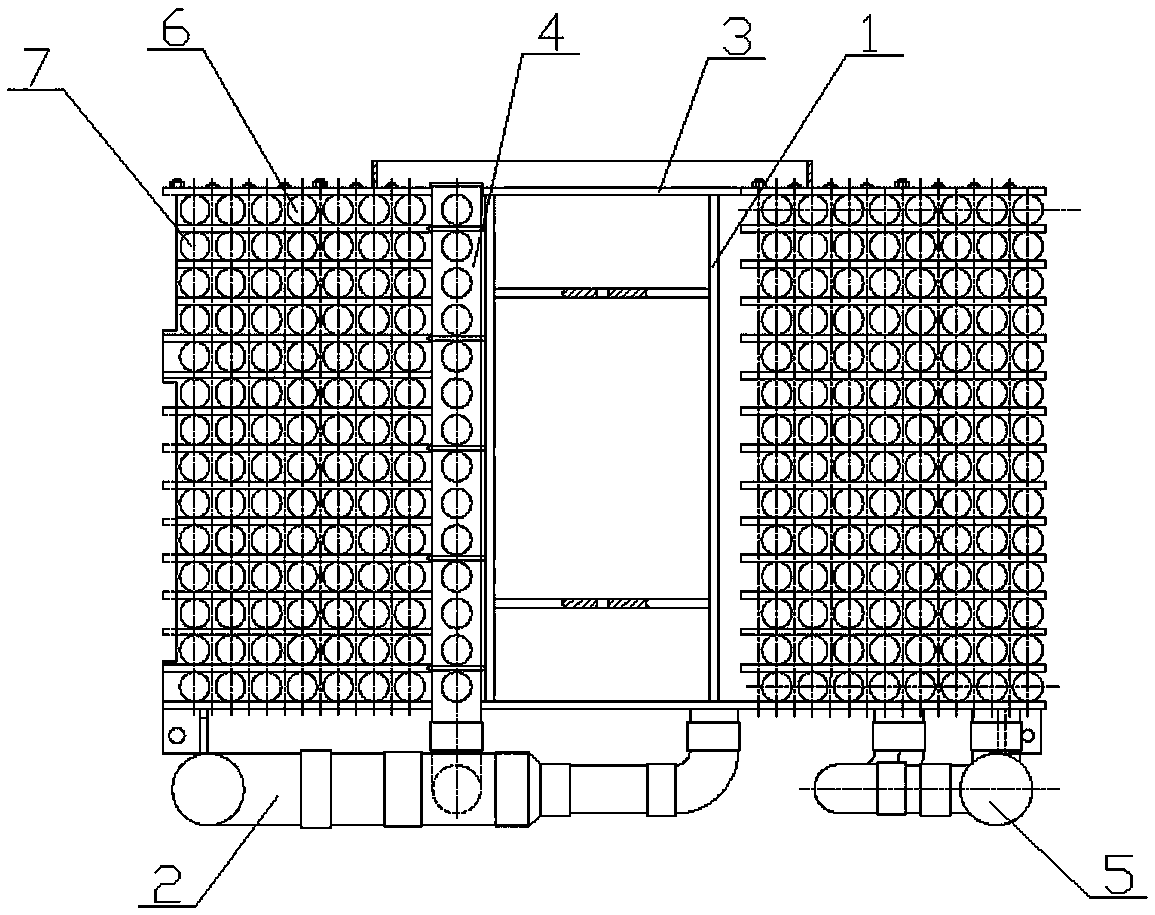

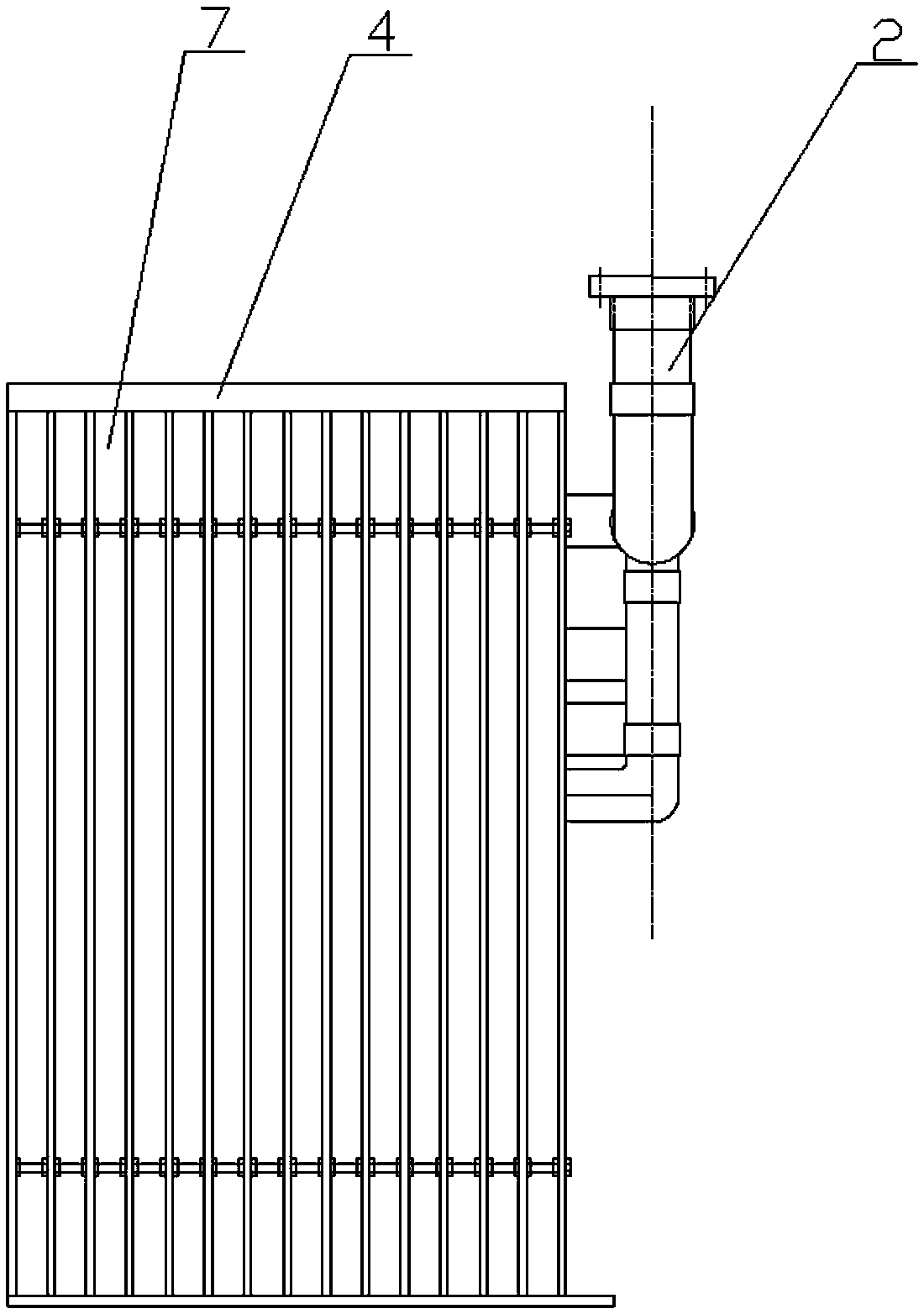

[0017] The row-type coil heat exchanger shown in the accompanying drawing is an embodiment used for the heat replacement of the rotating shaft support of a large heat treatment furnace. Heat exchange tube 6 and outer channel heat exchange tube 7. The frame 1 is a rectangular frame, and a bottom plate 1.2 parallel to the lower frame is provided inside, and the four corners of the bottom plate 1.2 are provided with vertical adjustment components 1.1. The upper frame of the frame 1 has built-in parallel pipe clips 1.3. The grid 3 such as image 3 As shown, it is a kind of thin plate, and the middle annular plate surface radially protrudes equal-length slats at intervals of 45°, and through holes are evenly distributed on the slats. The heat exchange elements in the present invention are the inner heat exchange tube 6 and the outer heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com