Device and method for synchronously measuring three-dimensional deformation and temperature with single camera under high temperature environment

A technology of three-dimensional deformation and high-temperature environment, which is applied in the direction of measuring devices, radiation pyrometry, and optical devices, etc., can solve the problems of low resolution and high price, and achieve the effect of convenient operation and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

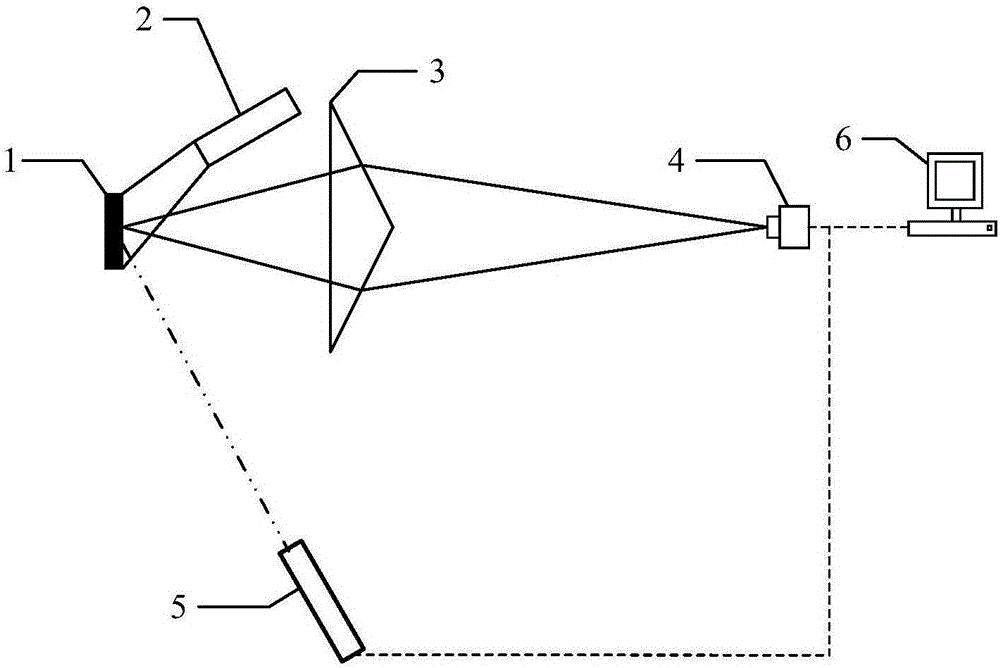

[0029] Such as figure 1 As shown, the single-camera three-dimensional deformation and temperature synchronous measurement device in the high-temperature environment of this embodiment includes: an illumination source 2, a color CCD camera 4, a filter, a single-camera binocular imaging system 3, an infrared thermometer 5, and a computer 6; Wherein, the illumination light source 1 emits the illumination light in the blue light band and irradiates the surface of the measured object 1; a filter is arranged in front of the lens of the color CCD camera, the transmission band of the filter is the blue light band, and the transmission center band corresponds to the band of the illumination source; The color CCD camera 4 and the infrared thermometer 5 are connected through a synchronization line and connected to the computer 6; the infrared thermometer 5 is aimed at the surface of the object to be measured; the color CCD camera 4 takes pictures of the object to be measured through the s...

Embodiment 2

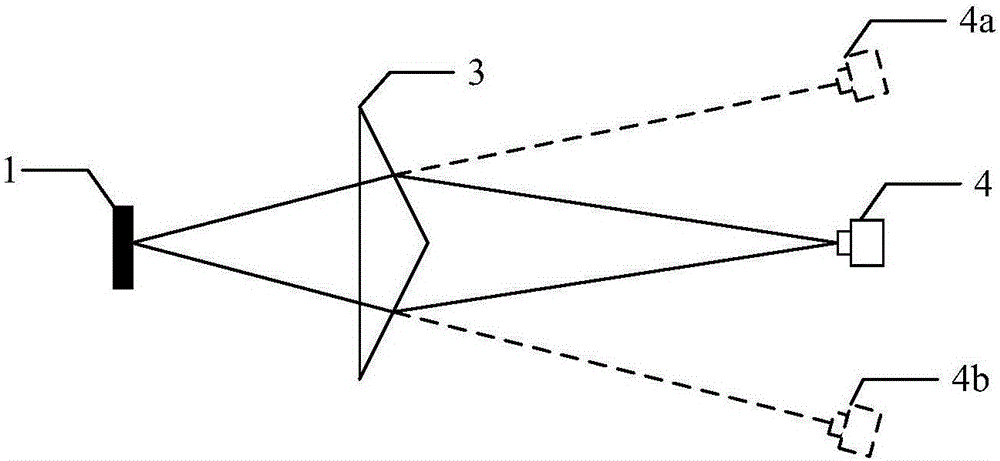

[0048] In this embodiment, the single-camera binocular imaging system 3 uses mirrors. Such as figure 2 As shown, the color CCD camera 4 shoots the surface of the measured object through the reflector, which is equivalent to two virtual cameras 4a and 4b shooting the surface of the measured object from different angles, thereby realizing the binocular vision effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com