Real-time automatic monitor system for wireless torque wrench

An automatic monitoring system and torque wrench technology, which is used to measure the direction of torque/torsion force during tightening, can solve problems such as scaffolding collapse, bolt tightening force requirements are not up to standard, and construction workers are lazy, so as to prevent excessive bolt tightening force Large or too small, enhanced work efficiency management, easy to understand and judge the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

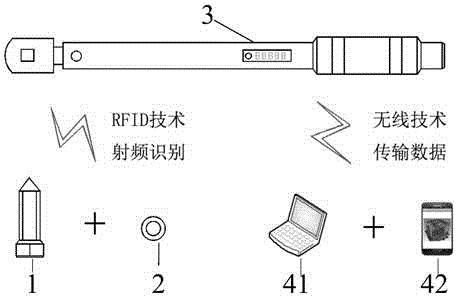

[0025] Such as Figure 1~3 As shown, the present invention also provides another wireless torque wrench real-time automatic monitoring system, including:

[0026] display terminal;

[0027] Scaffold node bolt 1, including electronic label 2, used to record the bolt number;

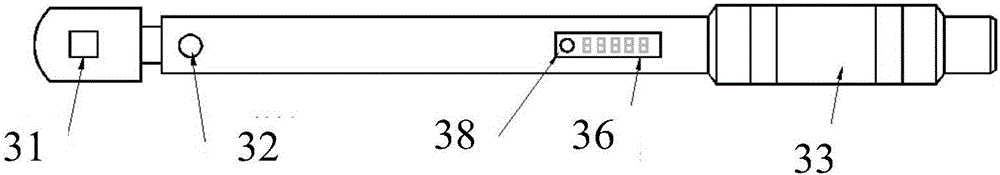

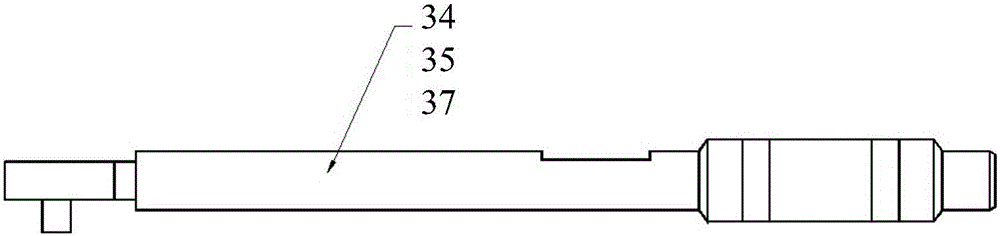

[0028] The wireless torque wrench 3 includes a bolt contact port 31, an electronic tag identification module 32 for identifying the information of the electronic tag 2, and a power supply module 33. The electronic tag identification module 32 is connected to the power supply module 33, wherein one wireless torque wrench corresponds to one For the operator, the electronic tag identification module is used to identify the bolt number; here, an operator corresp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap