High-low-temperature vacuum leak hole calibration device and method

A technology of vacuum leak hole and calibration device, applied in the field of measurement, can solve the problems of large measurement uncertainty, deviation of leak rate value, extension of calibration lower limit and reduction of measurement uncertainty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

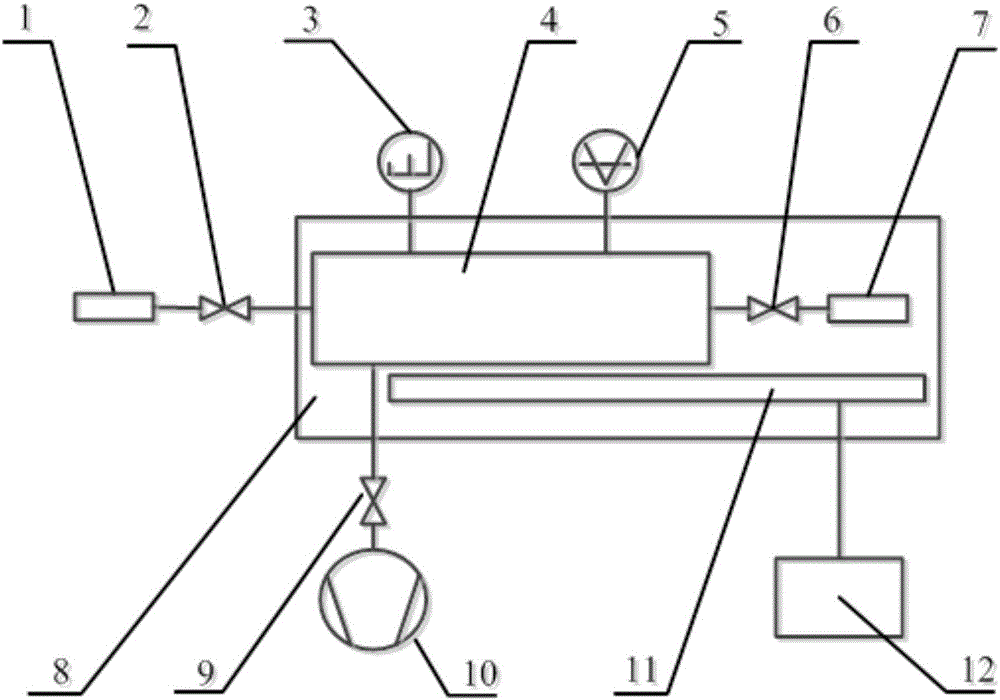

[0043] Such as figure 1 As shown, it is a high and low temperature vacuum leak calibration device in this embodiment. The main components of the device include a standard vacuum leak 1, a first valve 2, a mass spectrometer 3, a calibration chamber 4, a vacuum gauge 5, Second valve 6 , high and low temperature chamber 8 , third valve 9 , air extraction unit 10 , temperature control board 11 and temperature control system 12 .

[0044] Wherein, the standard vacuum leak hole 1 is connected with the calibration chamber 4 through the first valve 2, and is used to provide the standard gas flow rate in the calibration chamber 4; the air extraction unit 10 is connected with the calibration chamber 4 through the third valve 9, and is used for extracting gas, Realize vacuum; the vacuum leak 7 to be calibrated is connected with the calibration chamber 4 through the second valve 6, and placed in the high and low temperature chamber 8; the mass spectrometer 3 is connected with the calibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com