Oblique shallow settlement thickener uniform feeding device with half-type residue separators

A technology of feeding device and thickener, which is applied to the feeding/discharging device of sedimentation tank, sedimentation separation, chemical instruments and methods, etc. Effective performance, stable work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

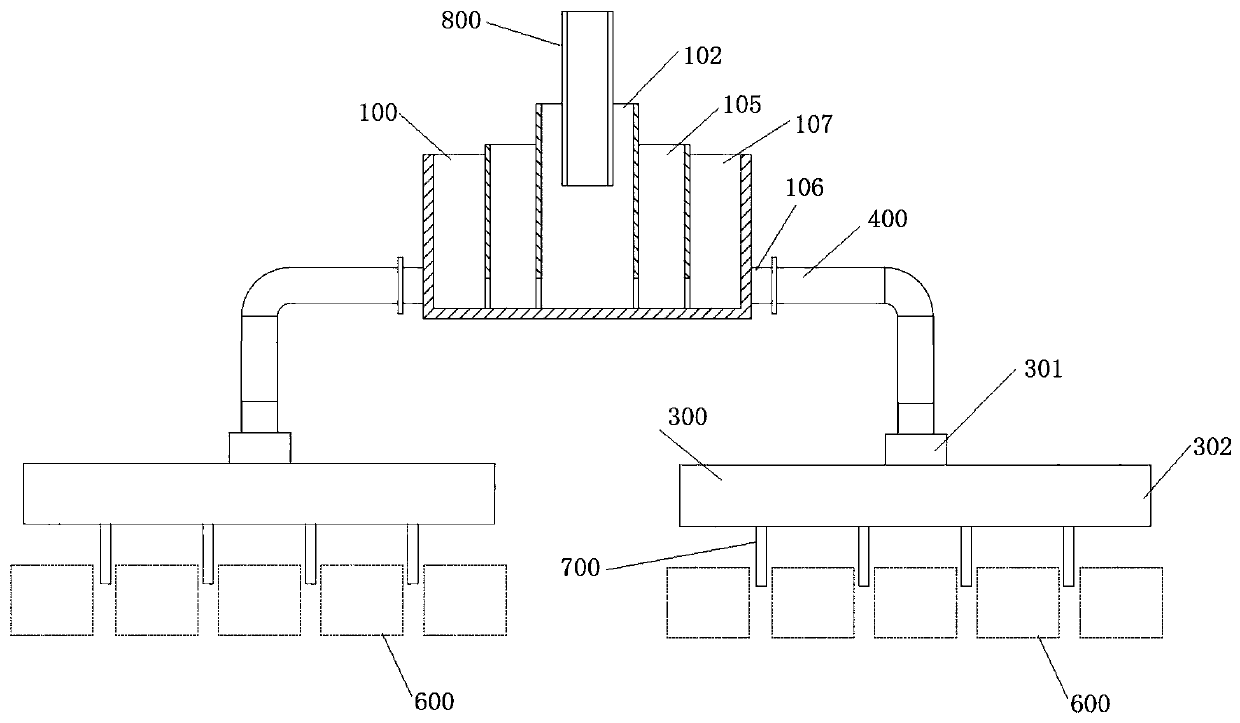

[0042] In a polymetallic sulfide ore dressing plant, ZXN-500 vibrating inclined plate settlement thickener is used for unilateral ore feeding. In the concentration of the middle ore after tin selection, use a ZXN-500 vibrating sloping plate oblique shallow layer thickener for concentration. The equipment has a total of 10 inclined plate settling modules, two cone buckets discharge underflow, and uses a set of uniform feeding device of the present invention.

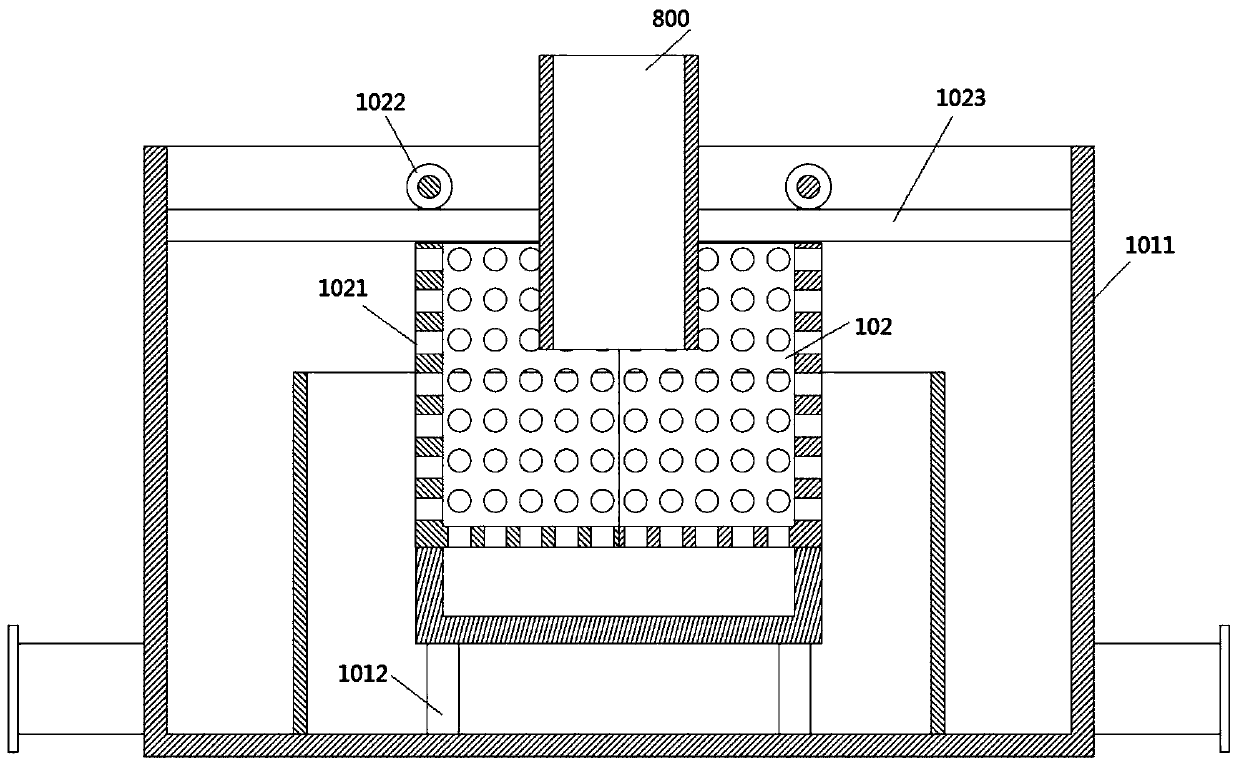

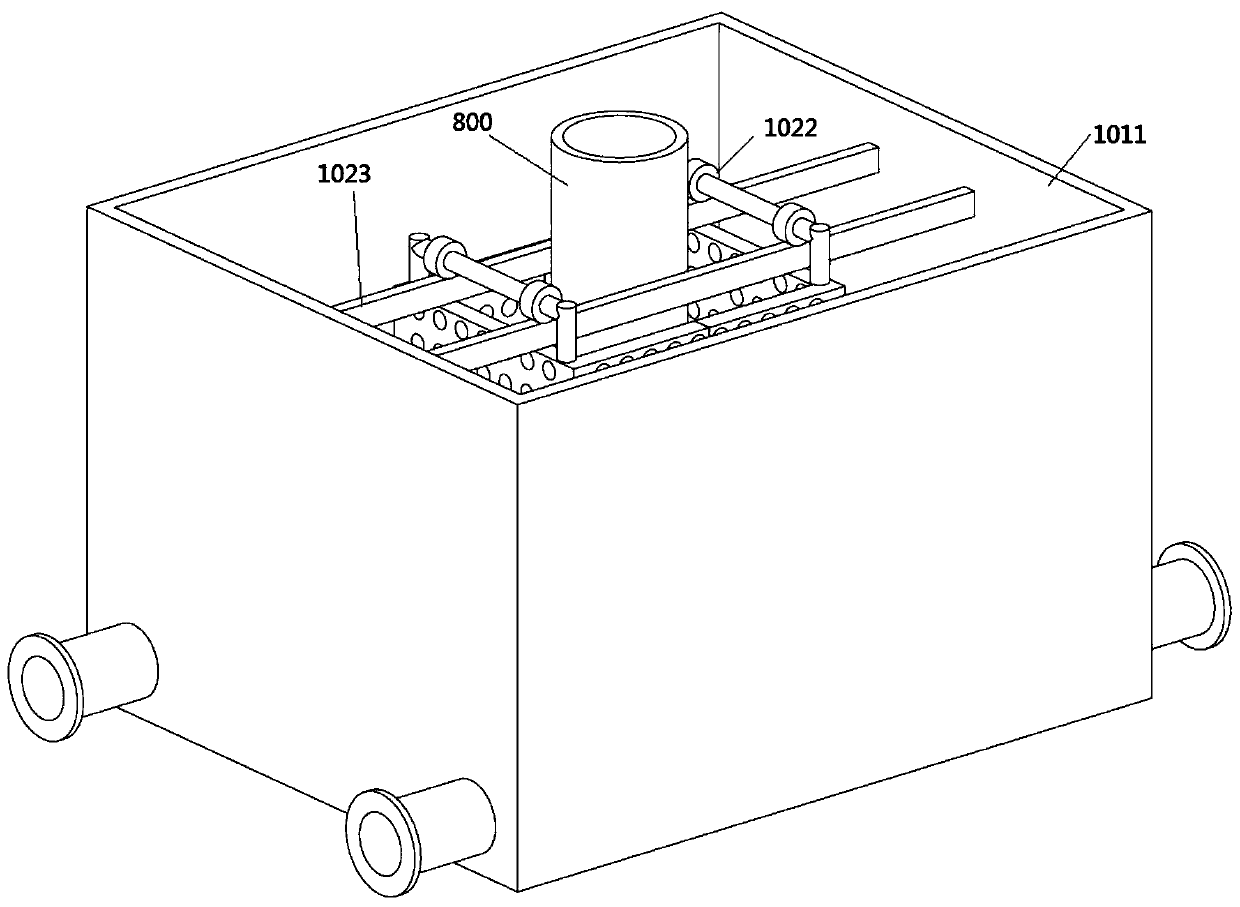

[0043] In the first-stage feeding unit 100, the shape of the feeding box 101 is a cuboid, and its length, width and height are 1000×500×1200mm. The interior is divided into sieve-type slag separators 102 by partitions of different heights. , the middle tank 105 and the ore-distributing channel 107. The length, width and height of the sieve-type slag separator 102 are 500×500×1000 mm, which is a complete through trough, and no isolation is required inside; the length, width and height of the middle tank 105 are 800×500×60...

Embodiment 2

[0048] In an iron ore concentrator, a ZXN-2400 vibration-type oblique box oblique shallow layer thickener is used to concentrate the fine-grained ore pulp in the tailings dry-drainage and heap concentration. The equipment has a total of 48 inclined box settling modules, eight cone buckets discharge the underflow, and two sets of uniform feeding devices with half-type slag separators of the present invention are used.

[0049] In the first-stage feeding unit 100, the shape of the ore feeding box 101 is a cuboid, and the length, width, and height dimensions are 1000×500×1200 mm. Sieve-type slag separator 102, in which wear-resistant material boards are laid to prevent the impact of ore pulp; outside the sieve-type slag separator 102, a middle tank 105 with a length, width and height of 800×500×600mm is set outside the middle tank 105 There is a mine-dividing channel 107 whose length, width and height are 1000×500×600mm. The sieve-type half-type slag separator 102 is made of wea...

Embodiment 3

[0054] An iron ore dressing plant contains a certain amount of phosphate ore, and the slurry needs to be concentrated and deslimed before the iron ore tailings are selected for phosphorus. A ZXN-1200 vibrating inclined box inclined shallow layer thickener is used to deslim the fine-grained ore pulp. The equipment has a total of 24 inclined box settling modules, four cone buckets discharge the underflow, and uses a set of uniform feeding device of the present invention.

[0055] In the first stage feeding unit 100, the profile of the ore feeding box 101 is a cylinder, and the external dimensions of a single device are Set the diameter at the middle position inside the mine box 101 to A sieve-type slag trap 102 with a height of 1200 mm. The sieve-type slag trap 102 is composed of two semicircular half-shaped slag traps 1021. The half-shaped slag trap is made of PE pipes. 103 and the bottom is opened with a diameter of hole. Outside the sieve type slag separator 102, the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com