Grain sampler

A sampling machine and grain technology, applied in sampling, sampling devices, measuring devices, etc., can solve the problems of inconvenient sampling operation, sampling detection deviation, sampling, etc., and achieve the effect of convenient sampling operation and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

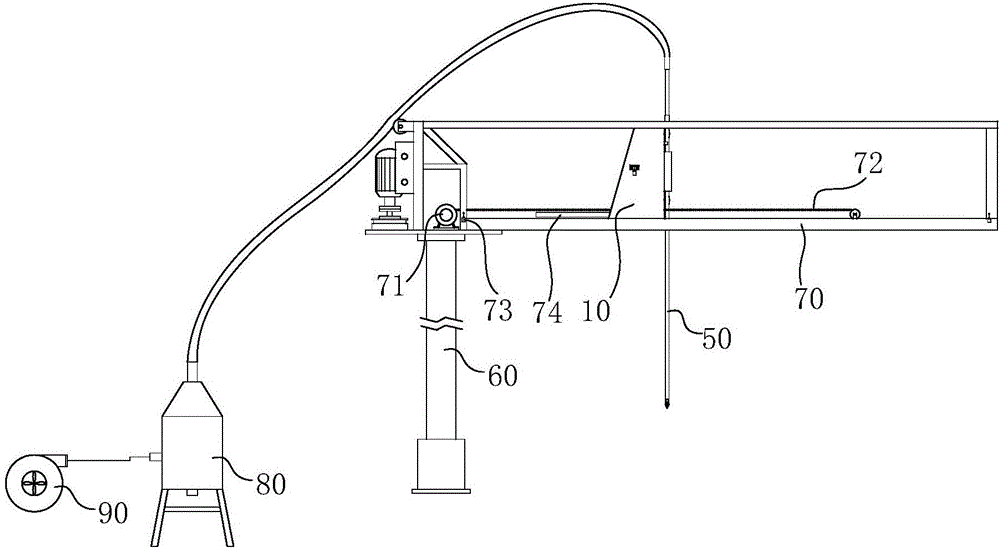

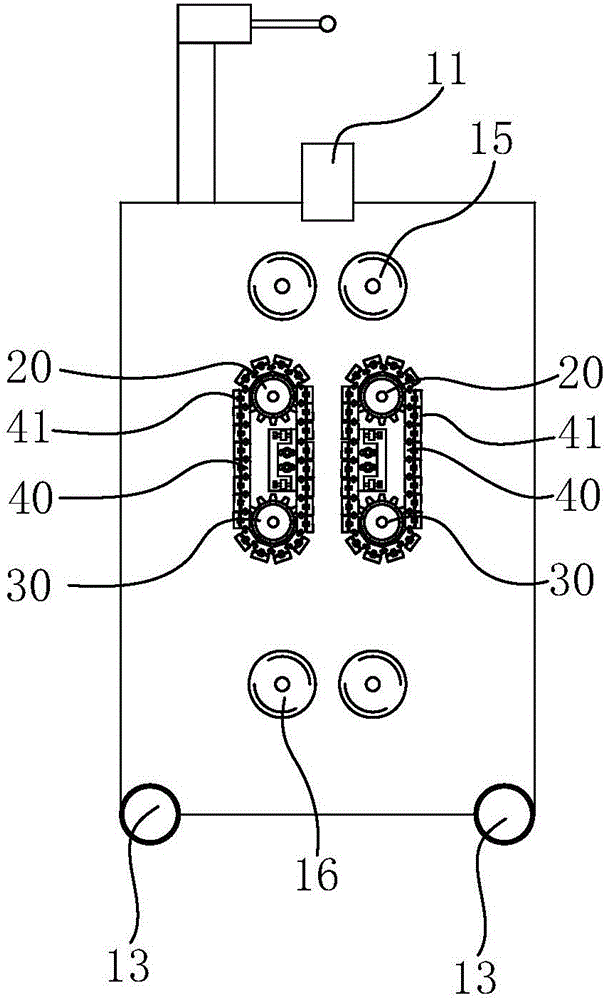

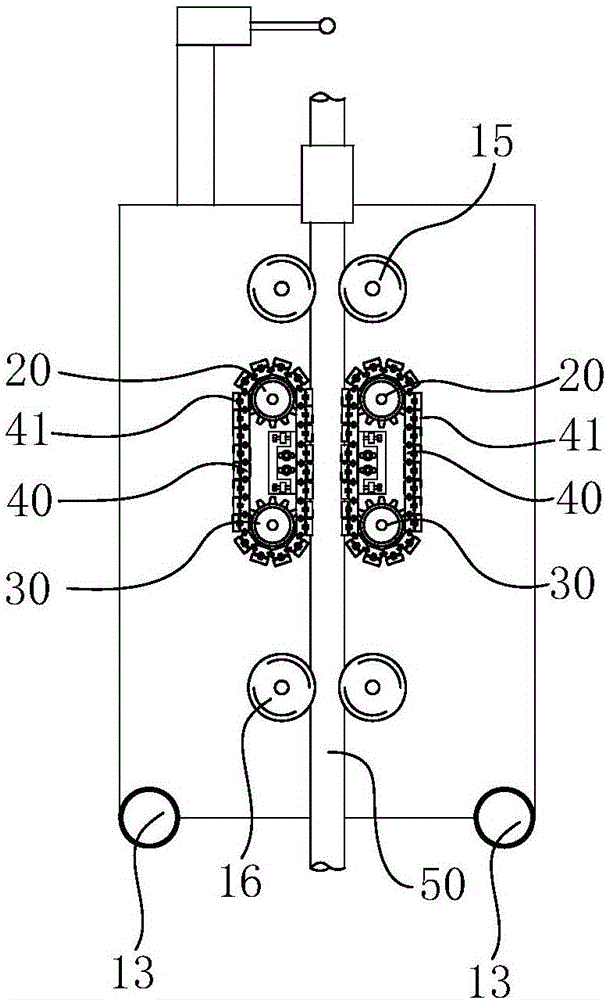

[0024] combine Figure 1 to Figure 8 , the present invention is further described:

[0025] Grain sampling machine, comprises column 60, is positioned at column 60 upper end and is arranged with horizontally extending cantilever frame 70, is provided with rotating mechanism between cantilever frame 70 and column 60, and rotating mechanism drives cantilever frame 70 to rotate around column 60, and described cantilever frame 70 A moving frame 10 is arranged on it, and the driving mechanism drives the moving frame 10 to reciprocate along the length direction of the cantilever frame 70. There are first and second guiding units arranged on the moving frame 10, and the first and second guiding units Each unit includes a driving gear 20 and a driven gear 30, the driving gear 20 and the driven gear 30 are connected by a transmission chain 40, and the connecting lines of the driving gear 20 and the driven gear 30 are vertical and respectively located at the sampling tubes to be clamped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com